Control method and system for oil return, air conditioner and computer readable storage medium

An oil return control and computer technology, which is applied to refrigerators, compressors, refrigeration components, etc., can solve the problem that the oil return function is not fully utilized, and achieve the effect of increasing the oil return and reducing the oil discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

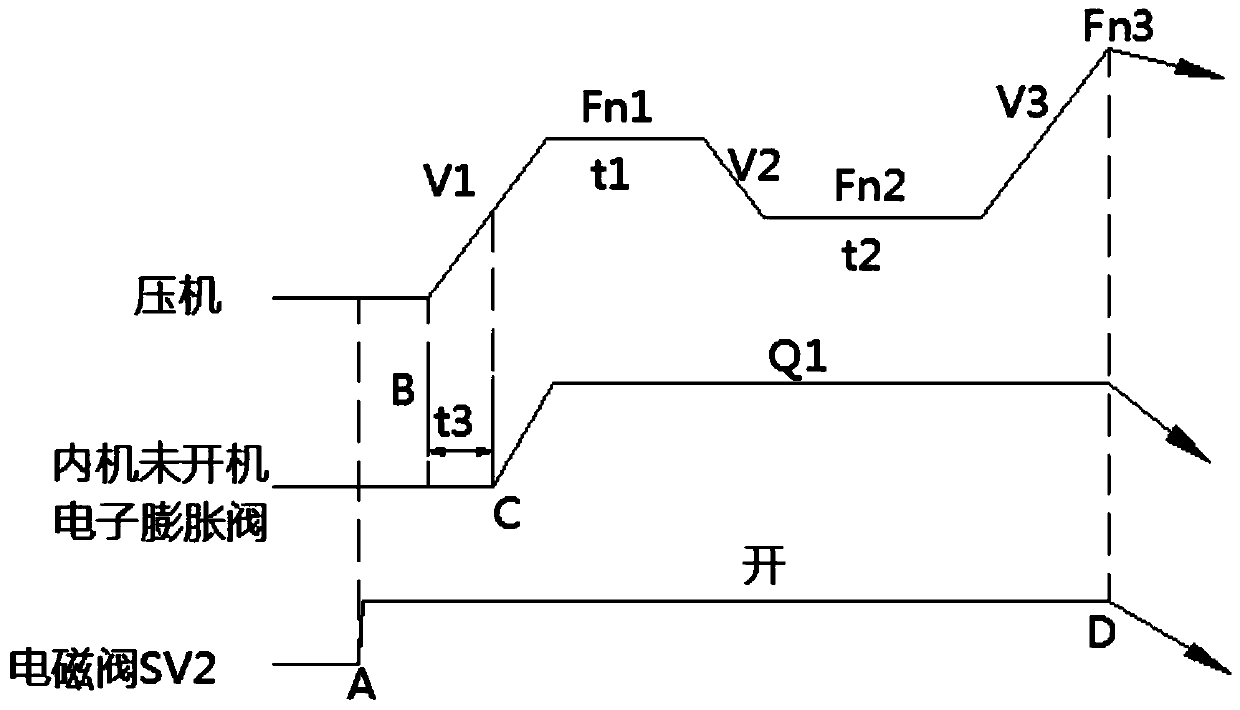

[0036] Such as figure 1 Shown, a kind of oil return control method comprises steps:

[0037] S1, when the outdoor ambient temperature package detects the temperature <T for 30 seconds in a row, T is -15°C to 0°C, and some indoor units are started, the outdoor unit receives the start command of the indoor unit, and the solenoid valve SV2 starts immediately;

[0038] S2, after power-on self-inspection, the compressor increases to Fn1 at the frequency increase rate V1, maintains the frequency at Fn1 for t1 seconds, then decreases the frequency at the increase rate of V2 and maintains the frequency at Fn2 for t2 seconds, then increases to Fn3 at the increase rate of V3 , and then start the platform automatically according to the normal operation;

[0039] S3, after the internal unit is not turned on, the electronic expansion valve adjusts the opening to the number of Q1 steps after t3 seconds after receiving the start signal of the compressor;

[0040] S4, after the start-up of ...

Embodiment 2

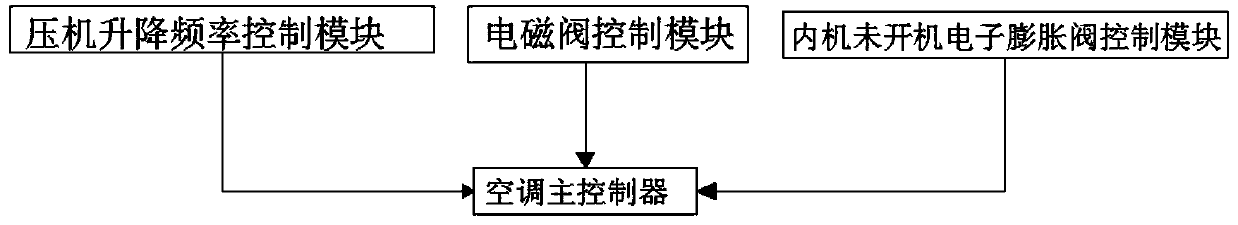

[0049] Such as figure 2 As shown, an oil return control system includes:

[0050] A compressor lifting frequency control module, the compressor lifting frequency control module can control the compressor to operate according to the set lifting frequency according to the compressor lifting frequency control command sent by the main controller of the air conditioner;

[0051] A solenoid valve control module, the solenoid valve control module controls the operation of the solenoid valve SV2;

[0052] The electronic expansion valve control module of the internal machine is not powered on, and the electronic expansion valve control module of the internal machine is not powered on to control the operation of the electronic expansion valve of the internal machine not powered on;

[0053] The main controller of the air conditioner, the main controller of the air conditioner controls the operation of the control module of the lifting frequency of the compressor, the control module of...

Embodiment 3

[0055] An air conditioner, the air conditioner includes the above-mentioned oil return control system, and the air conditioner also includes a computer-readable storage medium and a processor storing a computer program, and when the computer program is read and run by the processor , realizing the above oil return control method.

[0056] A computer-readable storage medium, where a computer program is stored in the computer-readable storage medium, and when the computer program is read and executed by a processor, the above oil return control method is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com