Electromechanical comprehensive support hanger and installation method thereof

A support and hanger, electromechanical technology, applied in the field of electromechanical integrated support and hanger and its installation, can solve the problems of poor stability of the support and hanger, material waste, hidden dangers, etc., to reduce work intensity, ensure site safety, and avoid loosening. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

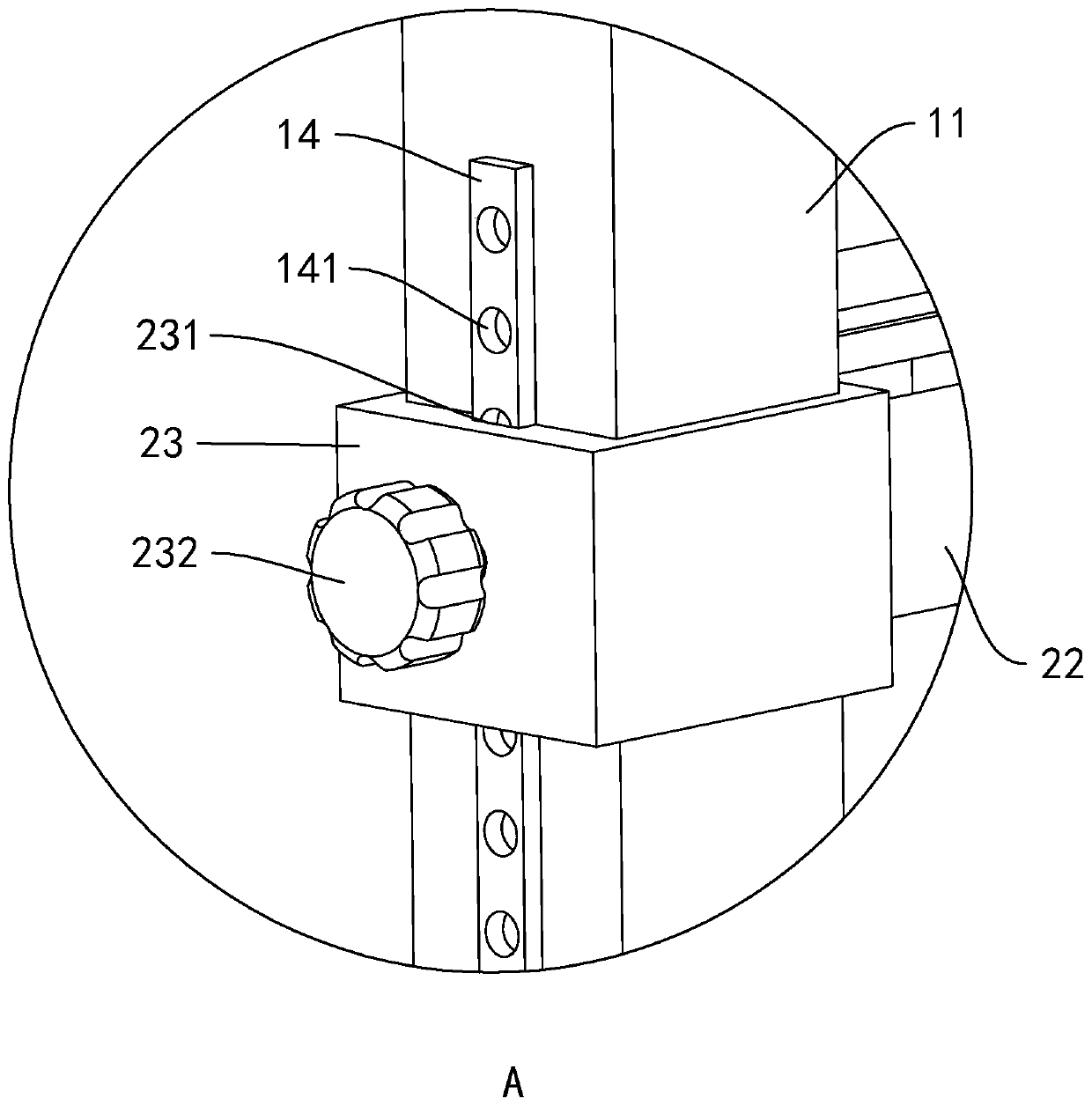

[0045] refer to figure 1 , is an electromechanical integrated support and hanger disclosed by the present invention, comprising a plurality of vertically arranged uprights 1, and the uprights 1 are arranged side by side at intervals in the transverse direction. A length-adjustable load-bearing beam 2 is arranged between adjacent columns 1 , and the load-bearing beam 2 can move vertically between adjacent columns 1 so as to adjust the position of the load-bearing beam 2 .

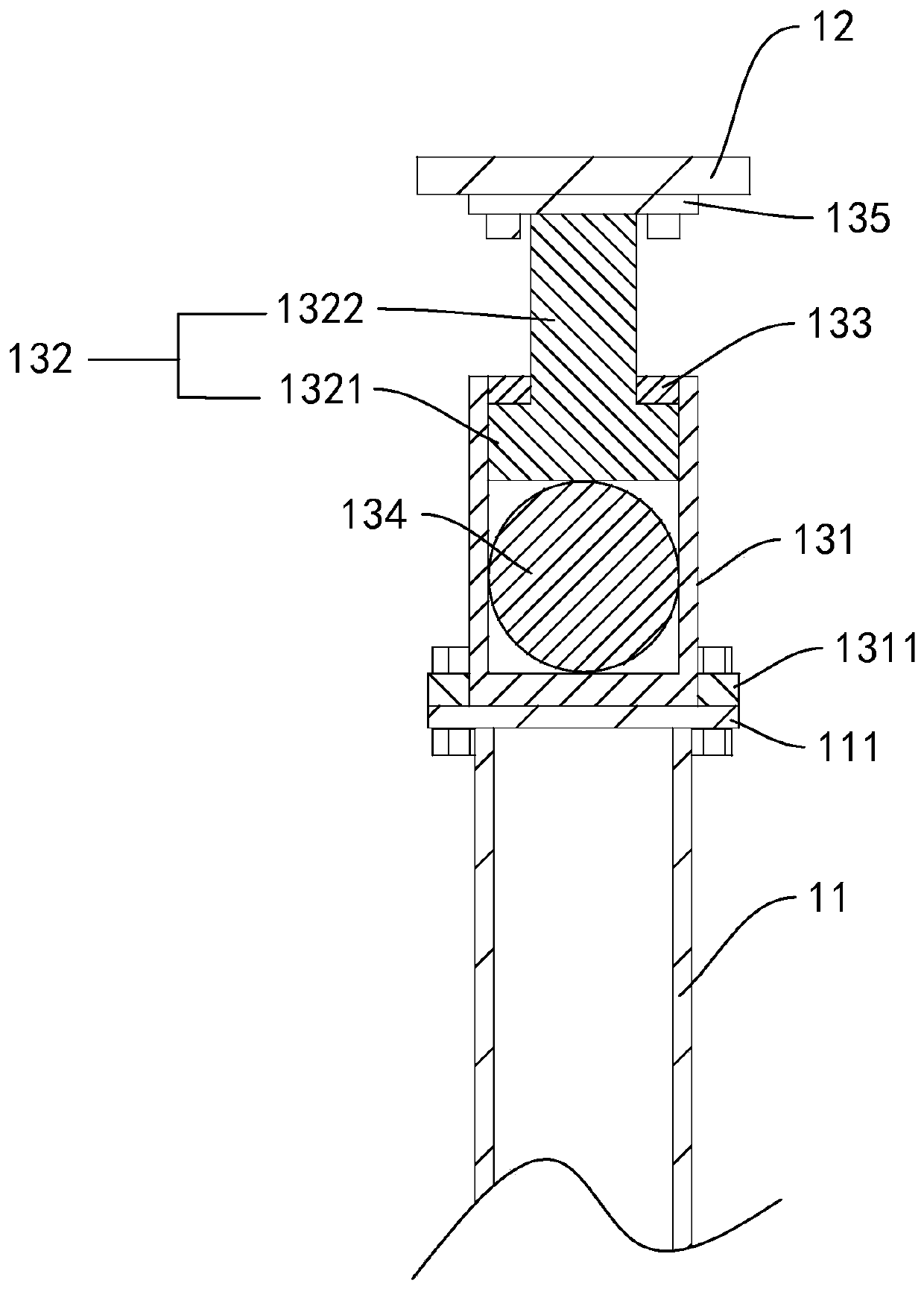

[0046] The column 1 includes a vertical body section 11, and the body section 11 adopts a square tube. A horizontal connection plate 12 is arranged on the top of the body section 11 , and a plurality of installation holes 121 vertically penetrating through the connection plate 12 are opened on the connection plate 12 . A shock-absorbing assembly 13 is arranged between the connecting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com