Trace powder distribution fluidization device

A fluidization device and powder separation technology, which is applied in jet propulsion devices, gas turbine devices, charging systems, etc., to avoid throttling, increase specific impulse, and enhance effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

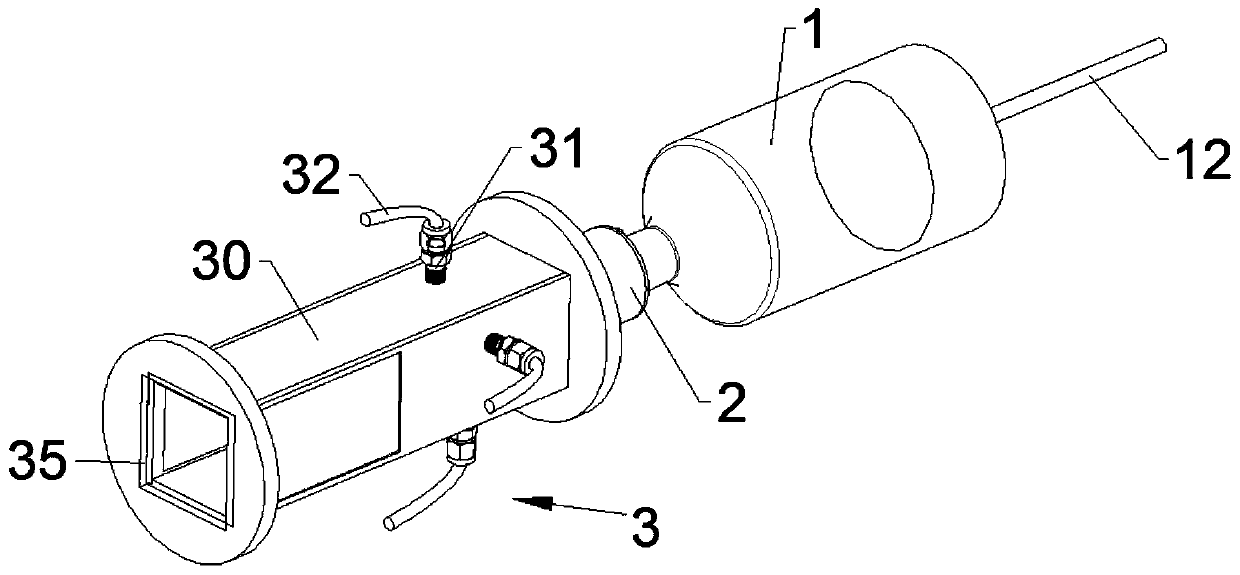

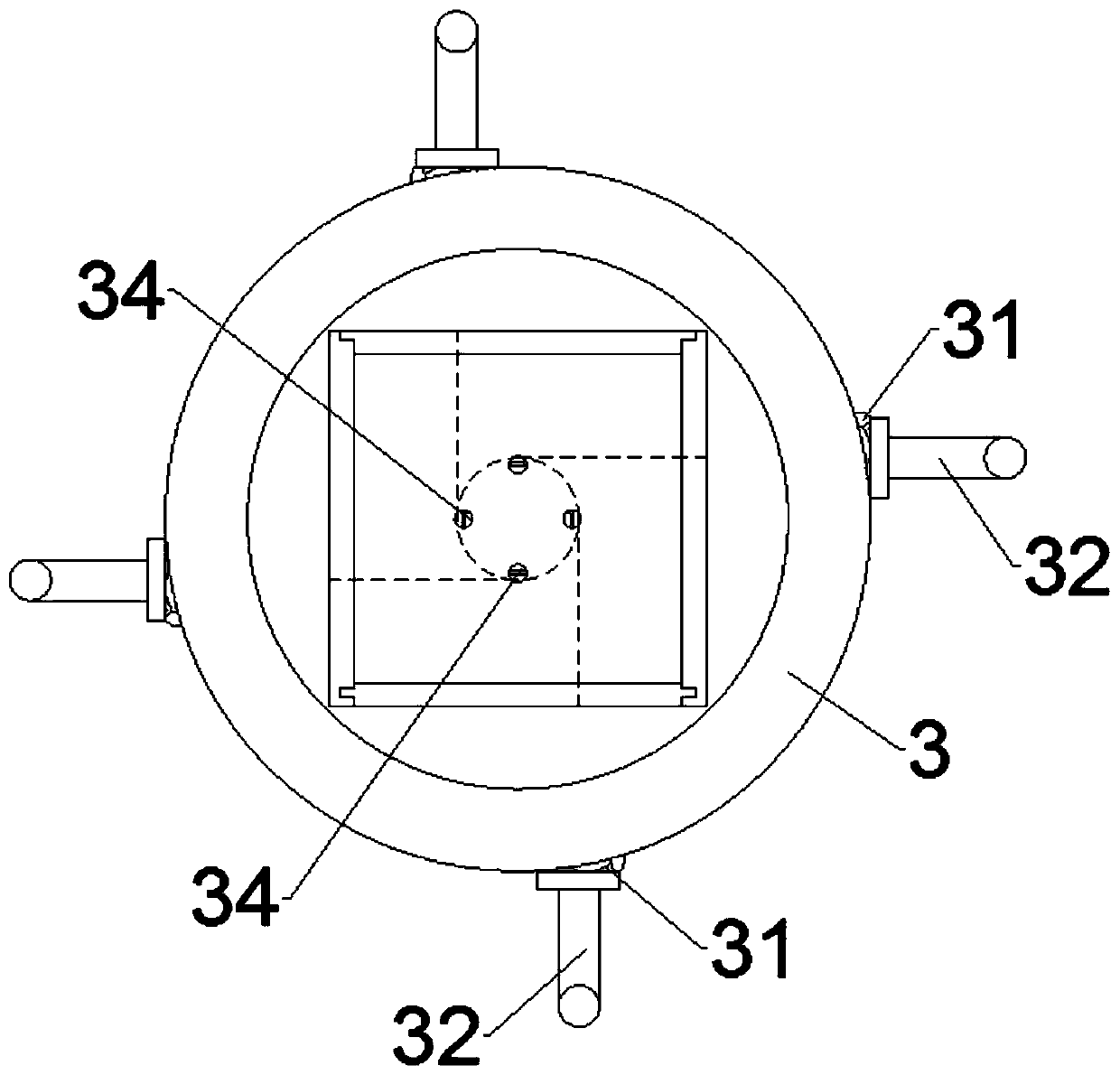

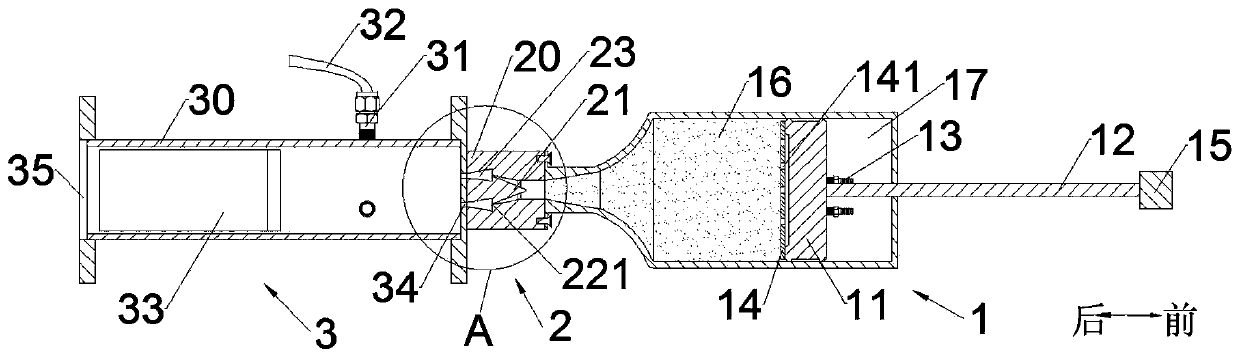

[0041] Embodiment 1 of the present invention provides a micro-powder distribution fluidization device, including a powder storage assembly 1, a powder distribution assembly 2, and an observation assembly 3, and the powder storage assembly 1, powder distribution assembly 2, and observation assembly 3 along the powder fuel The direction of supply is set sequentially from front to back.

[0042] The powder storage assembly 1 includes a powder storage housing 10, and a fuel grain column 16 is arranged inside the powder storage housing 10;

[0043] It should be noted that the fuel grain 5 in this embodiment can be made by using high-energy solid powder (aluminum, magnesium, boron, carbon, etc.) through existing techniques. In this embodiment, the high-energy solid powder is compacted and placed inside the powder storage shell 10 to obtain the fuel grain 5 with a certain degree of tightness.

[0044] The powder-distributing assembly 2 includes a powder-distributing housing 20, a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com