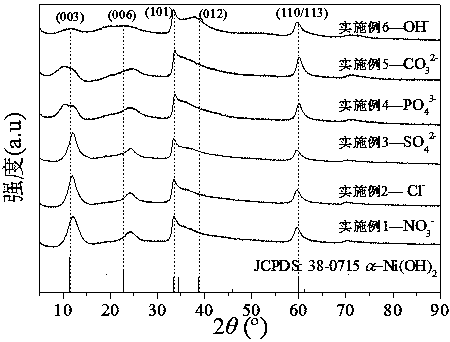

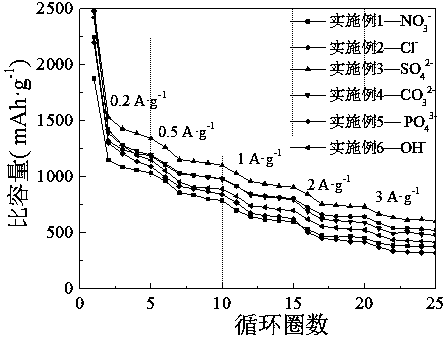

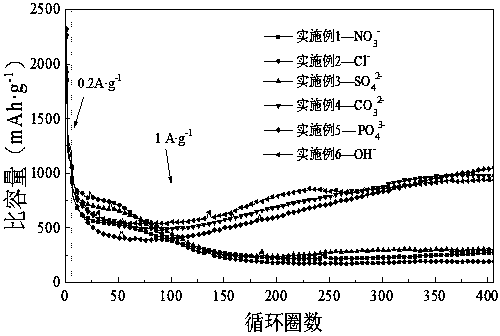

Method for optimizing lithium storage performance of alpha-Ni(OH)2 material

A performance and lithium storage technology, applied in the field of optimizing the lithium storage performance of α-Ni2 materials, can solve problems such as poor cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) Weigh nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) 0.02mol, dissolved in water to form 0.5mol / L Ni(NO 3 ) 2 solution; take urea by weighing the ratio of 30:1 by the molar ratio of urea and nickel nitrate hexahydrate and be made into urea solution of 6mol / L; Mix nickel nitrate solution and urea solution and disperse ultrasonically for 10 minutes to obtain uniform mixture.

[0016] (2) The mixed solution obtained in step (1) was placed in a constant temperature water bath, and stirred at 90° C. (stirring speed was 350 rpm) for 5 hours of reaction. After the reaction, the suspension obtained by the reaction was transferred to a dry box, aged at 60° C. for 12 hours, and then repeatedly suction-filtered and washed until the filtrate was neutral. Disperse the filter cake with water and freeze it in the refrigerator for 24 hours, then take it out and freeze-dry it to a constant weight, that is, the interlayer contains NO 3 - α-Ni(OH) 2 material, that achieves α...

Embodiment 2

[0018] (1) Weigh nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) 0.02mol, dissolved in water to form 0.5mol / L Ni(NO 3 ) 2 solution; take urea by weighing the ratio of 30:1 by the molar ratio of urea and nickel nitrate hexahydrate and be made into urea solution of 6mol / L; Mix nickel nitrate solution and urea solution and disperse ultrasonically for 10 minutes to obtain uniform mixture.

[0019] (2) The mixed solution obtained in step (1) was placed in a constant temperature water bath, and stirred at 90° C. (stirring speed was 350 rpm) for 5 hours of reaction. After the reaction, the suspension obtained by the reaction was transferred to a dry box, aged at 60° C. for 12 hours, and then repeatedly suction-filtered and washed until the filtrate was neutral. Disperse the filter cake with water and put it in the refrigerator for 24 hours to freeze, then take it out and freeze-dry it to constant weight to obtain the NO content in the interlayer. 3 - α-Ni(OH) 2 Material.

...

Embodiment 3

[0022] (1) Weigh nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) 0.02mol, dissolved in water to form 0.5mol / L Ni(NO 3 ) 2 solution; take urea by weighing the ratio of 30:1 by the molar ratio of urea and nickel nitrate hexahydrate and be made into urea solution of 6mol / L; Mix nickel nitrate solution and urea solution and disperse ultrasonically for 10 minutes to obtain uniform mixture.

[0023] (2) The mixed solution obtained in step (1) was placed in a constant temperature water bath, and stirred at 90° C. (stirring speed was 350 rpm) for 5 hours of reaction. After the reaction, the suspension obtained by the reaction was transferred to a dry box, aged at 60° C. for 12 hours, and then repeatedly suction-filtered and washed until the filtrate was neutral. Disperse the filter cake with water and put it in the refrigerator for 24 hours to freeze, then take it out and freeze-dry it to constant weight to obtain the NO content in the interlayer. 3 - α-Ni(OH) 2 Material.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com