Roller type rail clamping device

A roller type and roller technology, which is applied in the field of roller type rail clamping devices, can solve the problems of unreliable work, large influence of electromagnets and high cost, and achieve the effects of reducing operating costs, simplifying structure and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

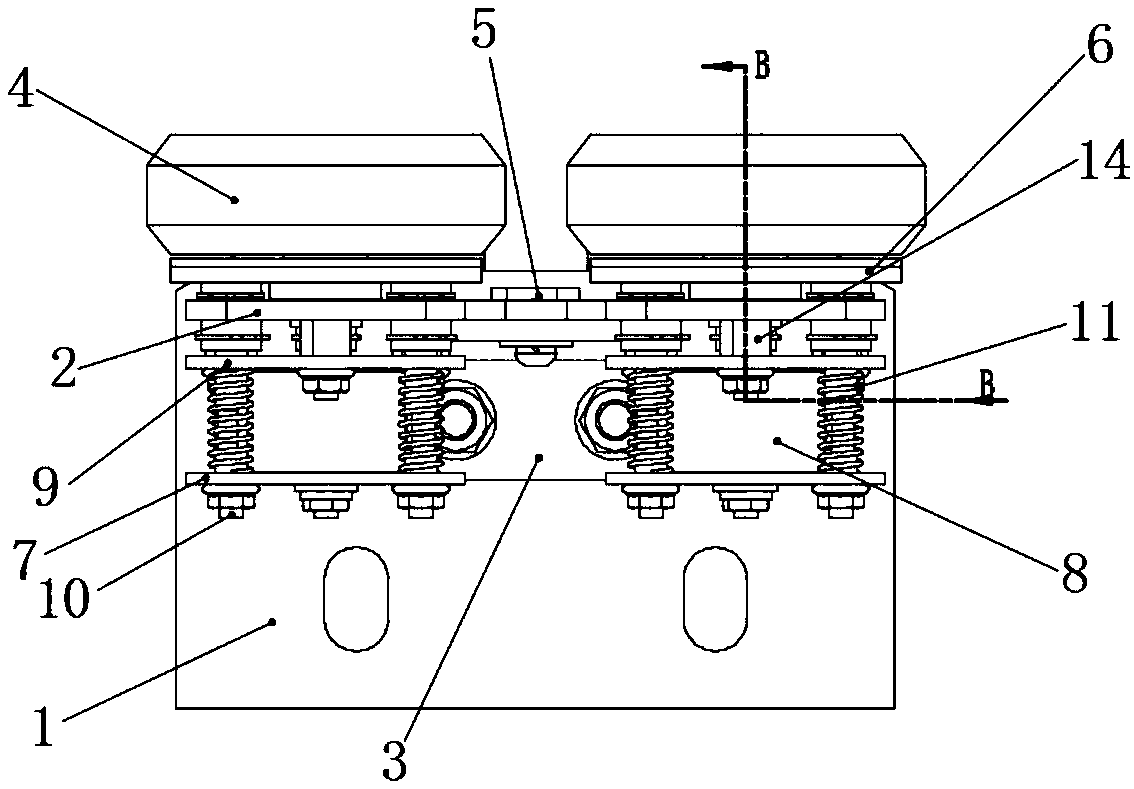

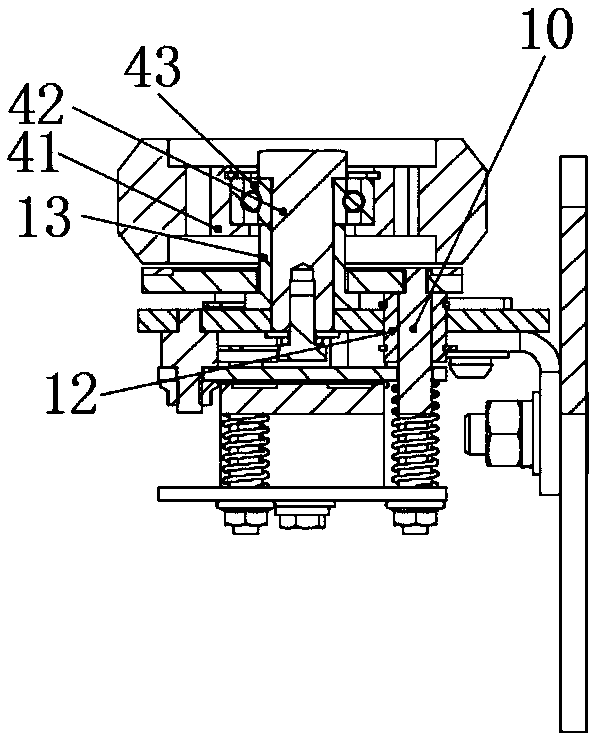

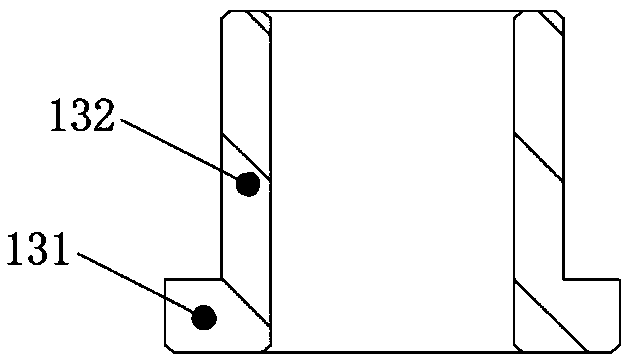

[0034] Such as Figure 1-5 As shown, the roller-type rail clamping device of this embodiment is applied to an elevator to keep the elevator in a stable running state. Specifically, the roller-type rail clamping device includes a base 1 and a turret 2 rotatably fitted on the base 1. Specifically, the base 1 is a rectangular plate structure, and the base 1 is equipped with a mounting frame 3 along the central axis of its long side. ,Such as Figure 4 As shown, the mounting frame 3 is an L-shaped structure, including a horizontal portion 31 and a vertical portion 32. The horizontal portion 31 of the mounting frame is fixedly connected to the base 1 by bolts or screws. For example, the bolts pass through the base 1 sequentially from bottom to top. The horizontal portion 31 of the mounting frame is fixed by nuts above the horizontal portion 31 of the mounting frame; among them, the base 1 and the horizontal portion 31 of the mounting frame are fixed by two bolts distributed on the...

Embodiment 2

[0049] The difference between the roller type rail clamping device of the present embodiment and the first embodiment is that:

[0050] The drive assembly can also be replaced by drive mechanisms in the prior art such as spring drive, motor drive, hydraulic drive, pneumatic, etc., as long as the friction disc is driven towards the roller direction and a certain driving force can be applied to make the friction disc restrain the roller. just move. Realize the diversification of the structure of the braking mechanism to adapt to different installation conditions, so that the application range of the roller-type rail clamping device of this embodiment is wider.

[0051] Other structures can refer to Embodiment 1.

Embodiment 3

[0053] The difference between the roller type rail clamping device of the present embodiment and the first embodiment is that:

[0054] The brake rollers can be in the same group as the guide rollers of the roller guide shoe, and a braking mechanism is added to the roller guide shoe to form an integrated device of the roller guide shoe and the roller-type rail clamping device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com