Bevel gear coaxial contra-rotating double-rotor transmission mechanism

A technology of transmission mechanism and gear transmission, which is applied to gear transmission devices, rotorcraft, and transmission devices to drive multiple propellers, etc., which can solve the problems of low bearing capacity and low reliability of compound high-speed helicopters, and reduce gear transmission. The effect of load and system quality, high reliability, and compact system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

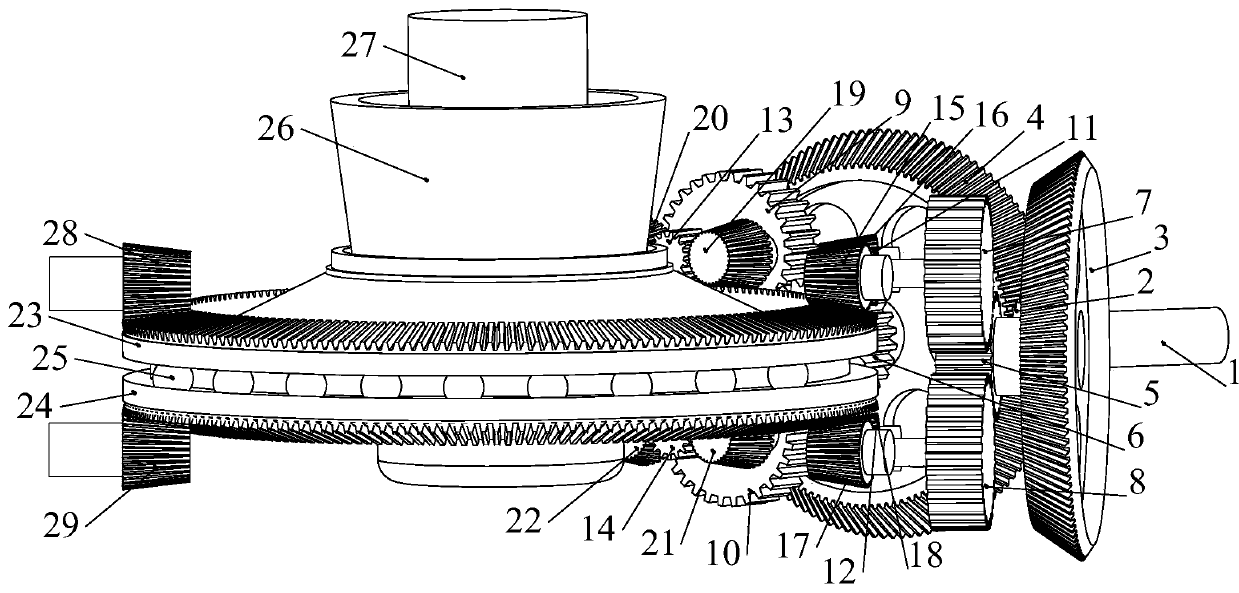

[0031] Embodiment 1: This embodiment is a structure of a bevel gear coaxial counter-rotating double-rotor transmission mechanism input by a single engine, such as figure 1 Shown: including three-stage torque splitter unit and coaxial output part;

[0032] The above-mentioned three-stage torque splitting unit is a three-stage fixed-axis gear train, including I-stage gear transmission, II-stage gear transmission and III-stage gear transmission;

[0033] The above-mentioned I-level gear transmission includes a power input shaft 1, and the power input shaft 1 is fixedly connected with the power input gear 2 to complete the first-level transmission of power; the power input gear 2 is connected to the first I-level face gear 3 and the second I-level face gear The gears 4 are meshed at the same time, and adopt radial floating support to complete the primary distribution of power;

[0034] The above-mentioned stage II gear transmission includes a first stage II small cylindrical gear...

Embodiment 2

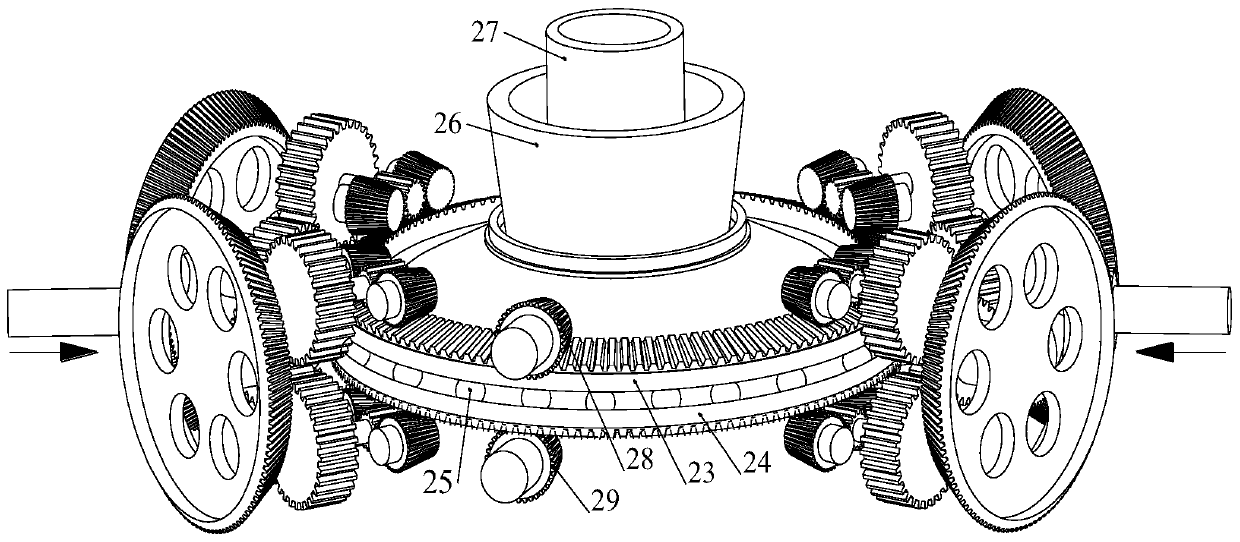

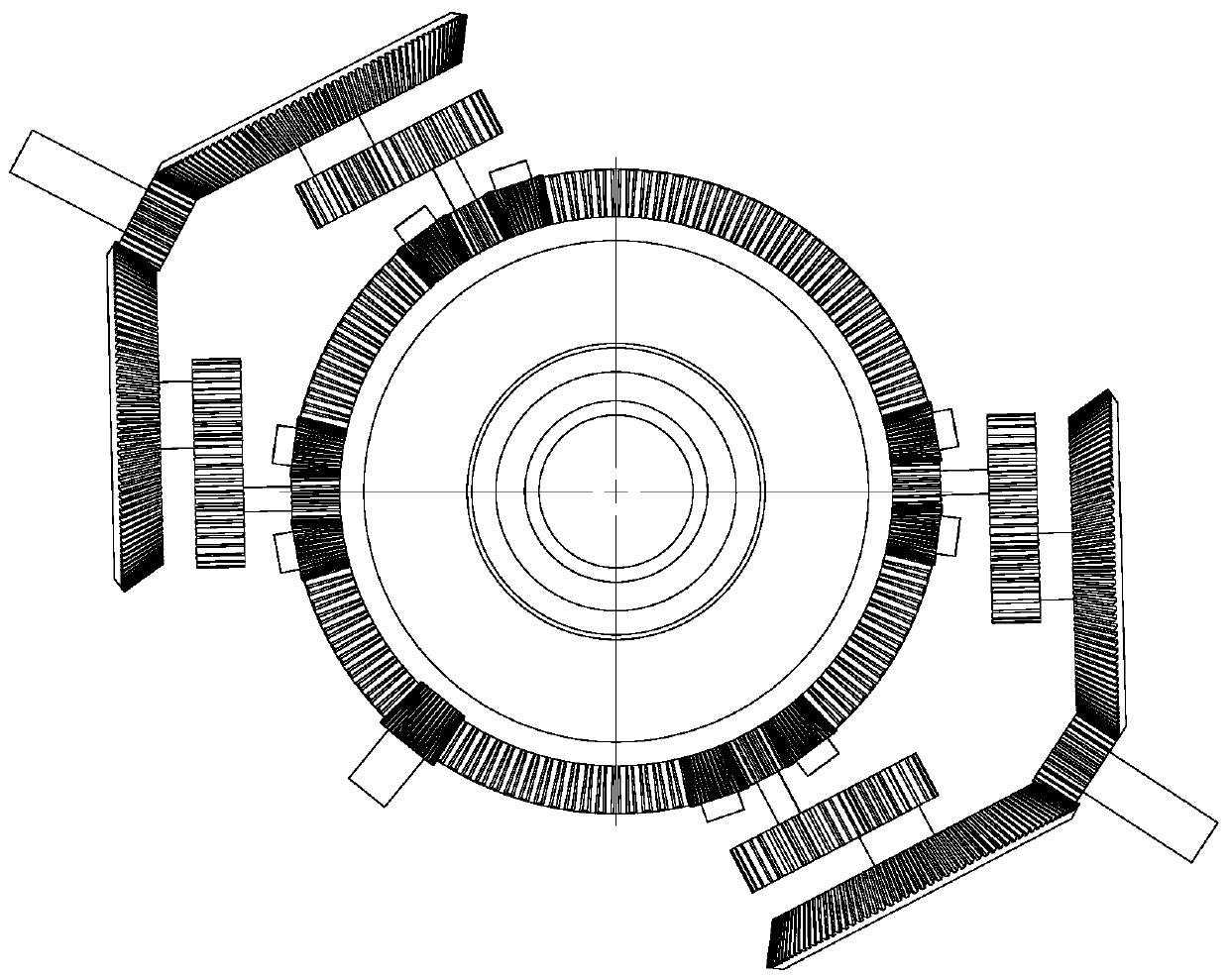

[0040] This embodiment is a structure of a bevel gear coaxial counter-rotating double-rotor transmission mechanism input by two engines, such as Figure 2-Figure 3 As shown: the structure is the same as that of the embodiment, the difference is that it adopts dual-engine power input, that is, it has two three-stage torsion splitter units with the same configuration, and they are distributed symmetrically or approximately symmetrically along the circumference.

[0041] The present invention increases the double-rotor combined mechanism on the basis of the double-engine input in the second embodiment, and adds the lower rotor 31 connected to the upper output shaft 26 and the upper rotor 30 connected to the lower output shaft 27, and the rest of the structure is the same as that of the second embodiment ,Such as Figure 4 shown.

[0042] The present invention has four times of power splitting and converging, mainly including three power splitting transmissions of three-stage fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com