Preparation process of environment-friendly flame-retardant insulating PVC cable material

A preparation process and cable material technology, applied in the field of preparation technology of environment-friendly flame-retardant insulating PVC cable material, can solve the problems of easy aging and cracking, affecting people's life and property safety, affecting visibility, etc., and improving the resistance to environmental stress cracking. and heat aging properties, protect health and property safety, and improve the effect of short-circuit withstand capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

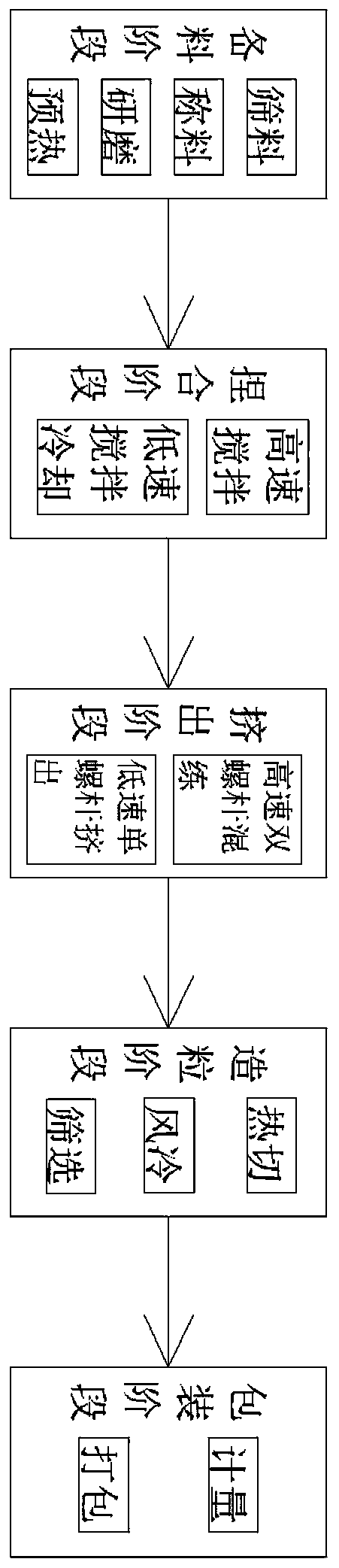

[0035] Such as figure 1 Shown is the process flow diagram of the present invention, including material preparation stage, kneading stage, extrusion stage, granulation stage and packaging stage; Said material preparation stage includes sieving, weighing, grinding and preheating; Described kneading stage includes high-speed Stirring and low-speed stirring cooling; the extrusion stage includes high-speed twin-screw mixing and low-speed single-screw extrusion; the granulation stage includes hot cutting, air cooling and screening; the packaging stage includes metering and packaging; wherein, the In the extrusion stage, an electron accelerator is installed at the discharge end of the low-speed single-screw extrusion.

[0036] The extrusion stage includes high-speed twin-screw kneading and low-speed single-screw extrusion, and the corresponding equipment is arranged vertically and orthogonally.

[0037] The high-speed twin-screw kneading temperature is 150-185° C., and the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com