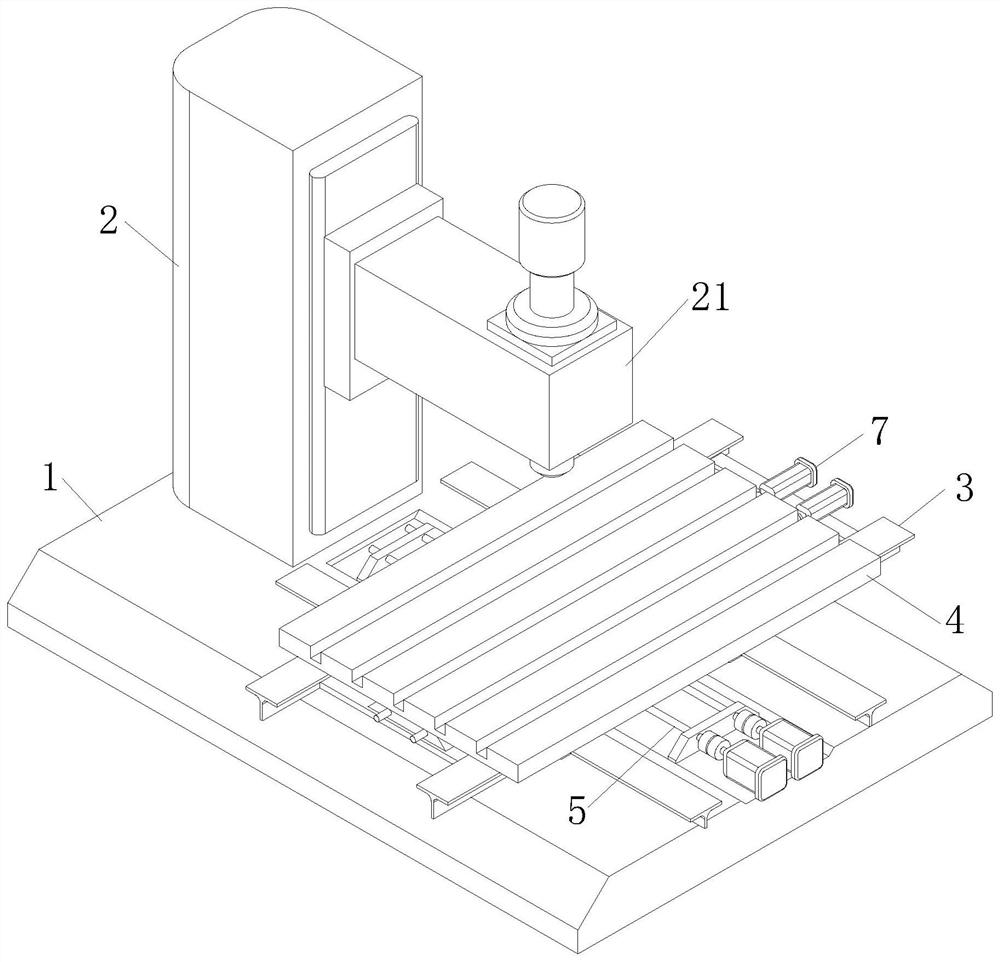

A high-precision CNC milling machine

A CNC milling machine, high-precision technology, applied in the direction of milling machines, milling machine equipment, manufacturing tools, etc., can solve the problems of milling machine worktable movement accuracy reduction, repeat positioning accuracy error, affecting processing accuracy, etc., to reduce additional effect and movement accuracy Guarantee and ensure the effect of processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

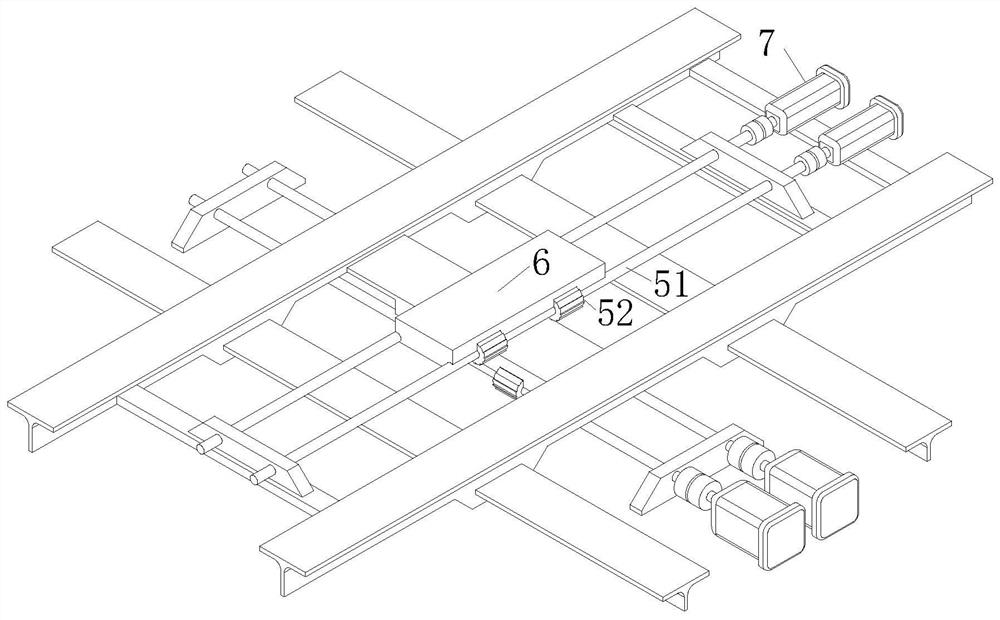

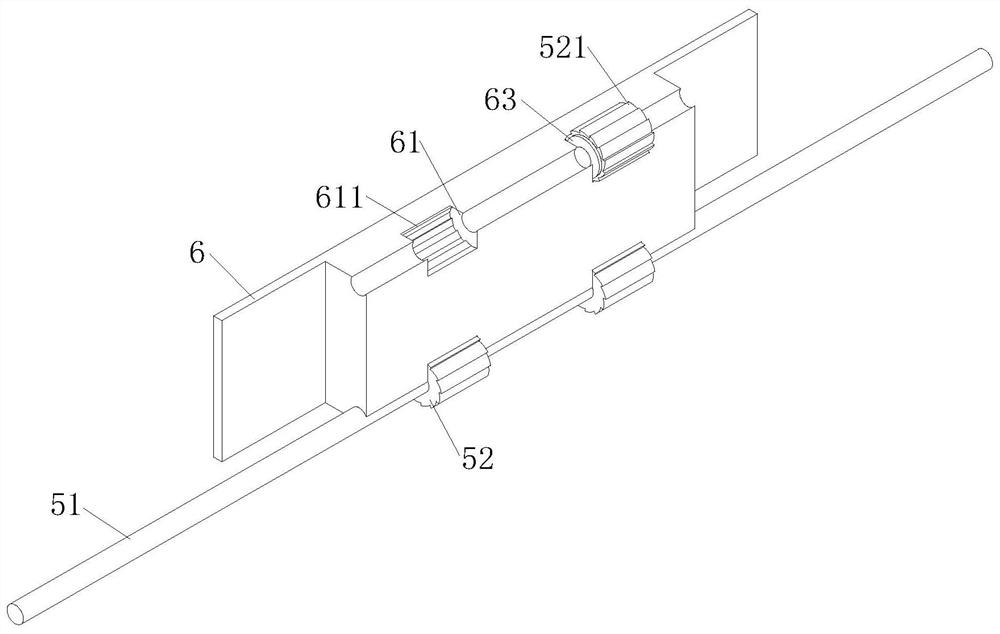

[0025] As an embodiment of the present invention, grooves 61 are provided on both sides of the transmission block 6, the shape of the grooves 61 is a partial cylinder, the size of the grooves 61 matches the nut 52, and the grooves 61 make the cylinder Part of the nut 52 is engaged in the groove 61 of the transmission block 6; the screw pair 5 controls the movement of the worktable 4 through the nut 52 engaged on the transmission block 6; when working, the servo motor 7 drives the screw rod 51 to rotate , so that the nut 52 on the lead screw pair 5 moves along the helical direction of the lead screw 51. Since the two moving directions of the transmission block 6 are controlled by the two lead screw pairs 5 respectively, when one lead screw pair 5 is driven, the other The lead screw pair 5 still needs to move with the transmission block 6, and does not interact with the transmission block 6; through the grooves 61 arranged on both sides of the transmission block 6, the nuts 52 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com