Method for frying low-oil flour-coated potato chips by using air fryer

An air fryer and frying technology, applied in the direction of food science, etc., can solve the problems of poor taste of French fries, high oil and high calorie affecting health, etc., to avoid water separation, maintain thickening ability, and look good Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

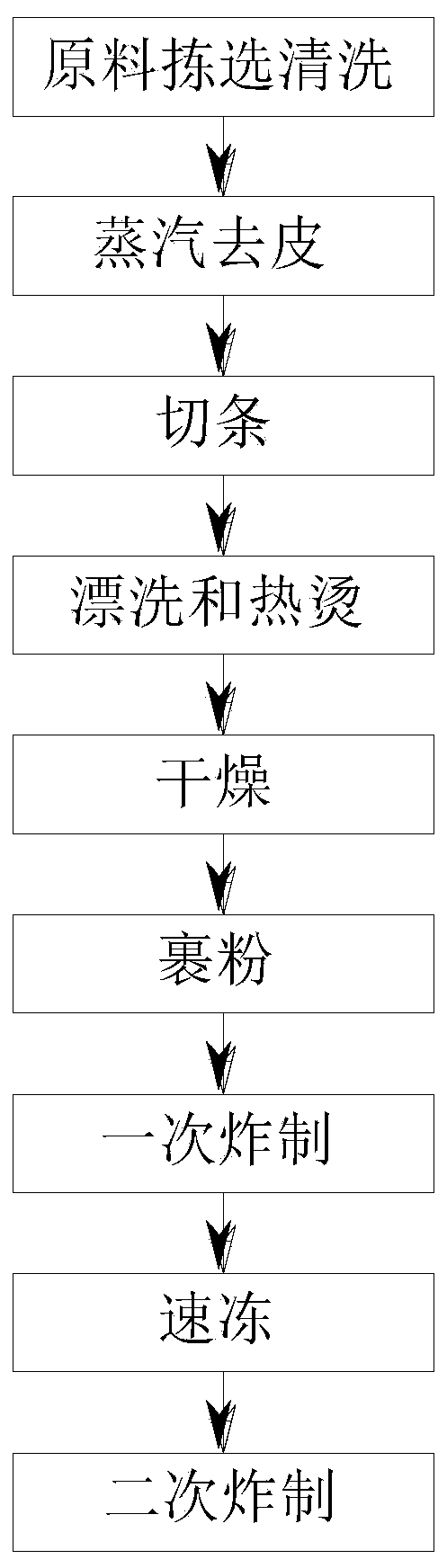

Image

Examples

Embodiment 1

[0030] A method for frying low-oil flour-coated French fries by using an air fryer, the method specifically includes the following steps:

[0031] Step 1: Selection and cleaning of raw materials, choose potatoes with no mildew, no insect eyes, no deterioration, shallow bud eyes, and smooth surface, and remove potatoes with green sprouts and dry skin, and clean the potatoes with the help of hydraulic and screw mechanisms. Physical and chemical indicators should be tested before production. The quality of physical and chemical indicators directly affects the color of the finished product. The reducing sugar content of potatoes should be less than 0.3%. If the reducing sugar content is too high, it should be placed in an environment of 15-18 °C In the middle, adjust for 2 to 4 weeks;

[0032] Step 2: Steam peeling, send the washed potatoes into the cooking tank, flash steam in the medium pressure steam, and discharge out of the tank, at this time, transport the cooked potatoes in...

Embodiment 2

[0041] A method for frying low-oil flour-coated French fries by using an air fryer, the method specifically includes the following steps:

[0042] Step 1: Selection and cleaning of raw materials, choose potatoes with no mildew, no insect eyes, no deterioration, shallow bud eyes, and smooth surface, and remove potatoes with green sprouts and dry skin, and clean the potatoes with the help of hydraulic and screw mechanisms. Physical and chemical indicators should be tested before production. The quality of physical and chemical indicators directly affects the color of the finished product. The reducing sugar content of potatoes should be less than 0.3%. If the reducing sugar content is too high, it should be placed in an environment of 15-18 °C In the middle, adjust for 2 to 4 weeks;

[0043] Step 2: Steam peeling, send the washed potatoes into the cooking tank, flash steam in the medium pressure steam, and discharge out of the tank, at this time, transport the cooked potatoes in...

Embodiment 3

[0052] A method for frying low-oil flour-coated French fries by using an air fryer, the method specifically includes the following steps:

[0053] Step 1: Selection and cleaning of raw materials, choose potatoes with no mildew, no insect eyes, no deterioration, shallow bud eyes, and smooth surface, and remove potatoes with green sprouts and dry skin, and clean the potatoes with the help of hydraulic and screw mechanisms. Physical and chemical indicators should be tested before production. The quality of physical and chemical indicators directly affects the color of the finished product. The reducing sugar content of potatoes should be less than 0.3%. If the reducing sugar content is too high, it should be placed in an environment of 15-18 °C In the middle, adjust for 2 to 4 weeks;

[0054] Step 2: Steam peeling, send the washed potatoes into the cooking tank, flash steam in the medium pressure steam, and discharge out of the tank, at this time, transport the cooked potatoes in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com