On-line denoising method for liquid pressure sensor system based on hidden Markov model

A liquid pressure and sensor technology, applied in the measurement of fluid pressure, instruments, complex mathematical operations, etc., can solve the problems of system noise and measurement noise limitation of the working performance of liquid pressure sensors, achieve online denoising, reduce measurement errors, The effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The online denoising method of the liquid pressure sensor system based on the hidden Markov model of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

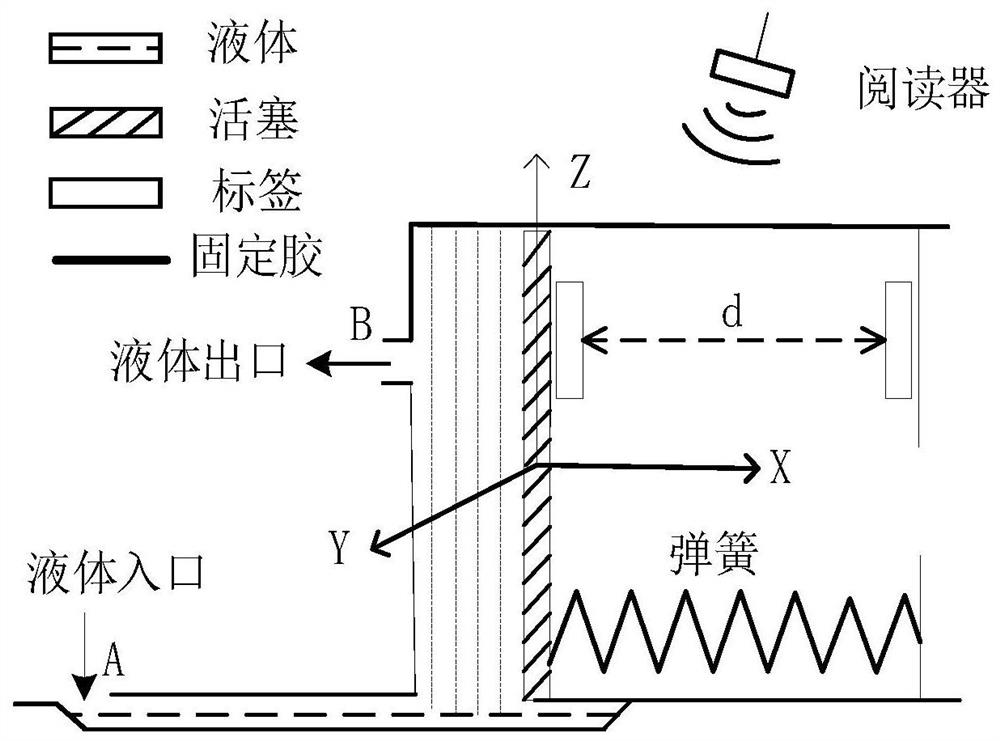

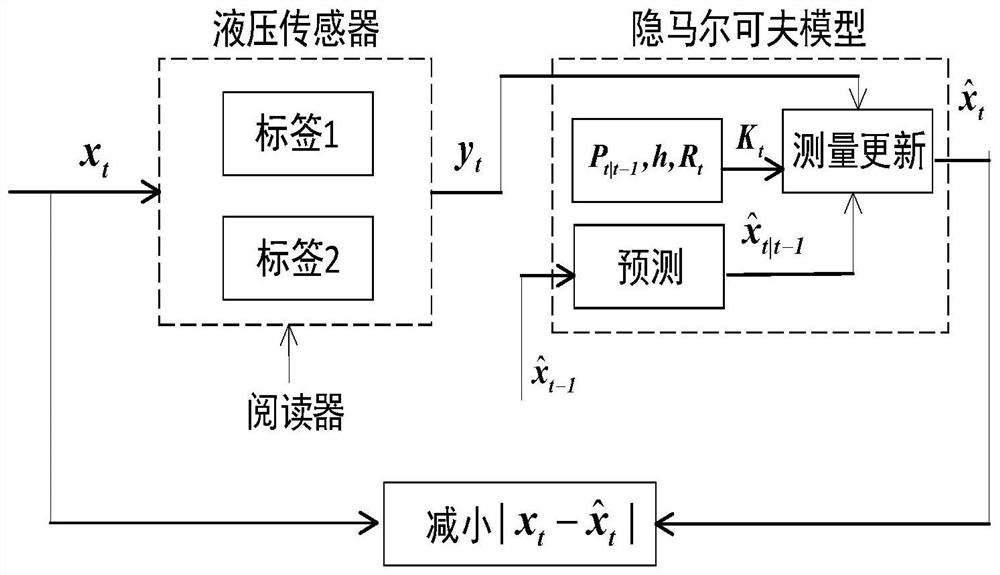

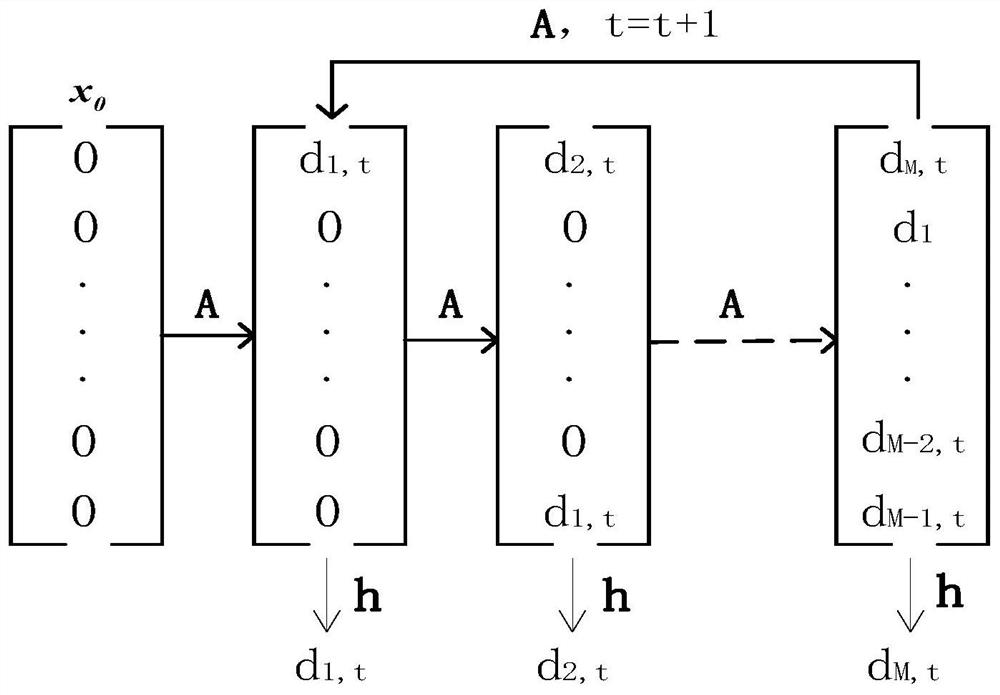

[0050] In the online denoising method of the liquid pressure sensor system based on the hidden Markov model of the present invention, the adopted liquid pressure sensor system is such as figure 1 As shown, the hydraulic pressure sensor utilizes radio frequency identification technology and adopts a dual tag coupling design. The two labels are respectively fixed on the piston and the cylinder wall by fixing glue, and are within the working range of the reader. Among them, the tag adopts a commercial chip with an adaptive impedance matching capacitor, and the reader can indicate the matching capacitor (C) of the tag, and the distance (d) between the matching capacitor (C) and the two tags satisfies C=k / d+ b, where k, b are constants. When the cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com