Pilot-operated type proportional flow valve with position and flow composite feedback function

A technology of proportional flow valve and composite feedback, which is applied in the direction of valve details, valve device, valve operation/release device, etc., can solve the problem that the control accuracy cannot meet the strict requirements of component control, and the thermal flow sensor has low dynamic response and cannot be very fast. To meet the needs of real-time control in the field of automation and other issues, to achieve the effect of reasonable structure, improved stability and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

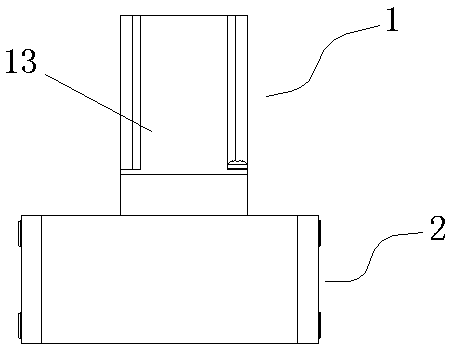

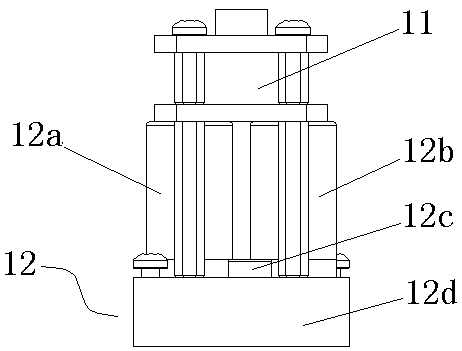

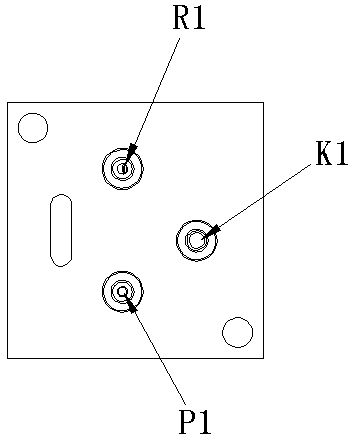

[0033] Such as Figure 1 to Figure 8 Shown is the structural representation of the present invention,

[0034] The reference signs are: first nonlinear characteristic relationship L1, linear relationship L2, second nonlinear characteristic relationship L3, pilot valve inlet P1, pilot valve pressure relief port R1, pilot valve control port K1, main valve supply Air port P2, main valve exhaust port R2, main valve control port K2, working port A, pilot valve 1, controller 11, processor 11a, M / A analog-to-digital converter 11b, input / output interface circuit 11c, display Circuit 11d, power supply 11e, solenoid valve drive circuit 11f, pilot valve module 12, intake solenoid valve 12a, exhaust solenoid valve 12b, pressure sensor 12c, air circuit bottom plate 12d, outer casing 13, main valve 2, pilot valve interface 2a , right control chamber 2b, v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com