High-pressure water pump

A high-pressure water pump and water pumping technology, applied in the direction of pumps, multi-cylinder pumps, liquid displacement machines, etc., can solve the problems of complex structure, large volume, high failure rate, etc., and achieve simple control, space saving, and reduced oil circuits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

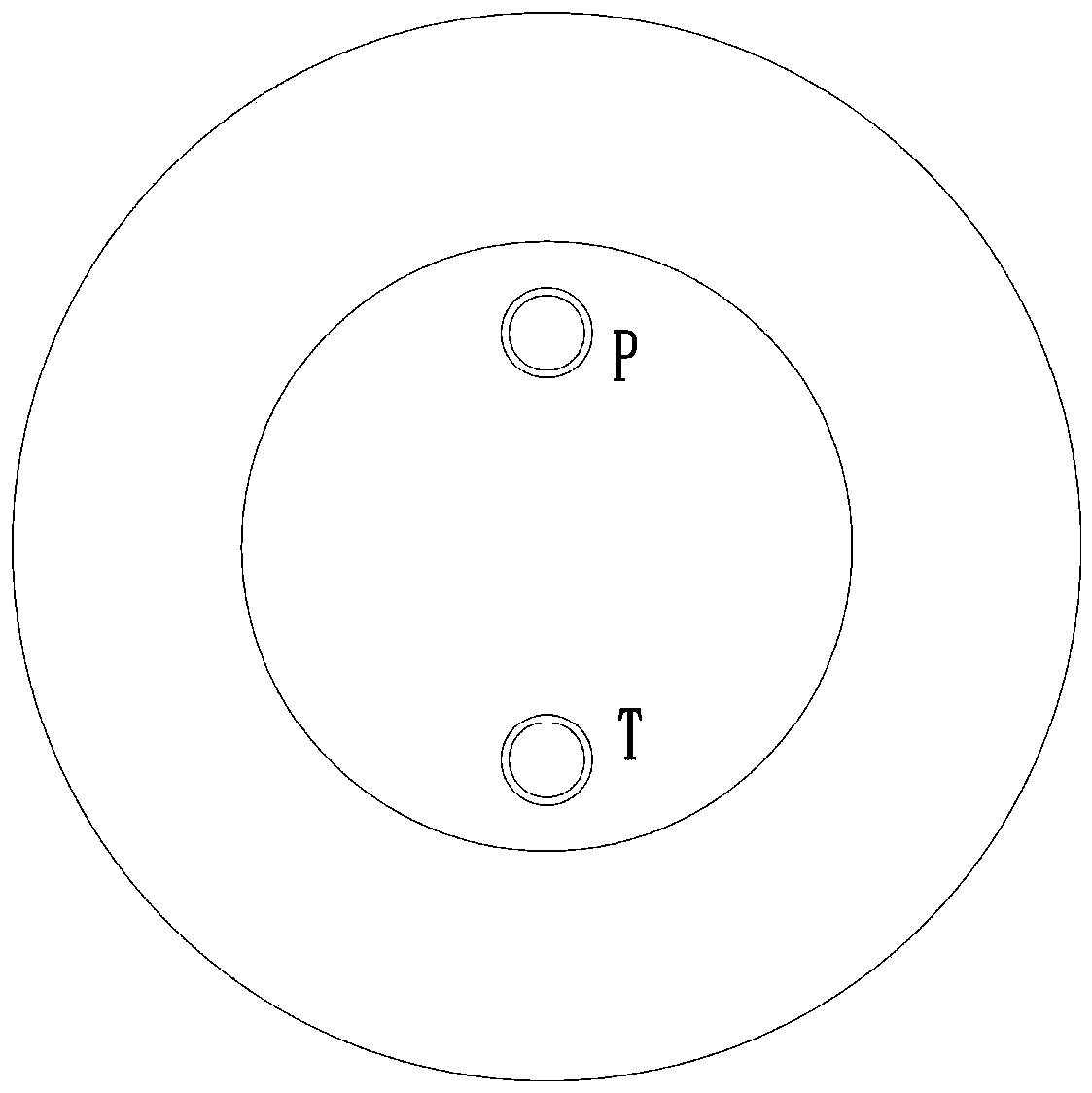

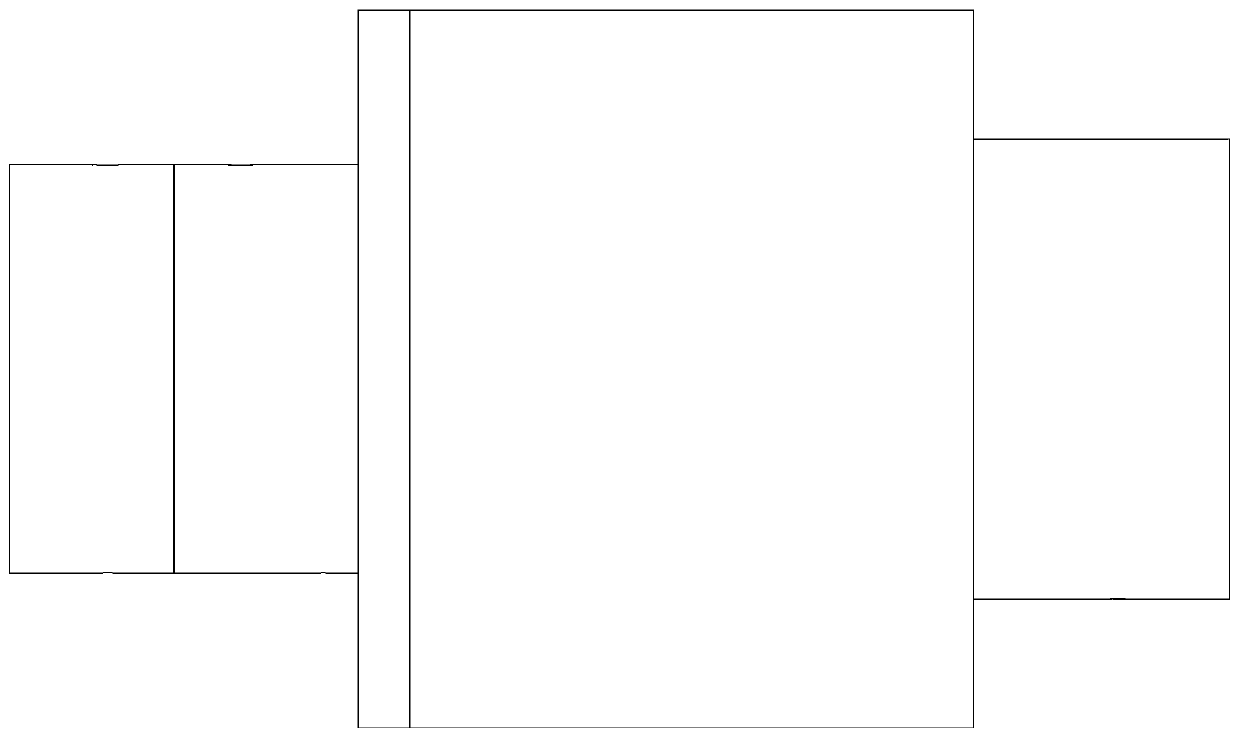

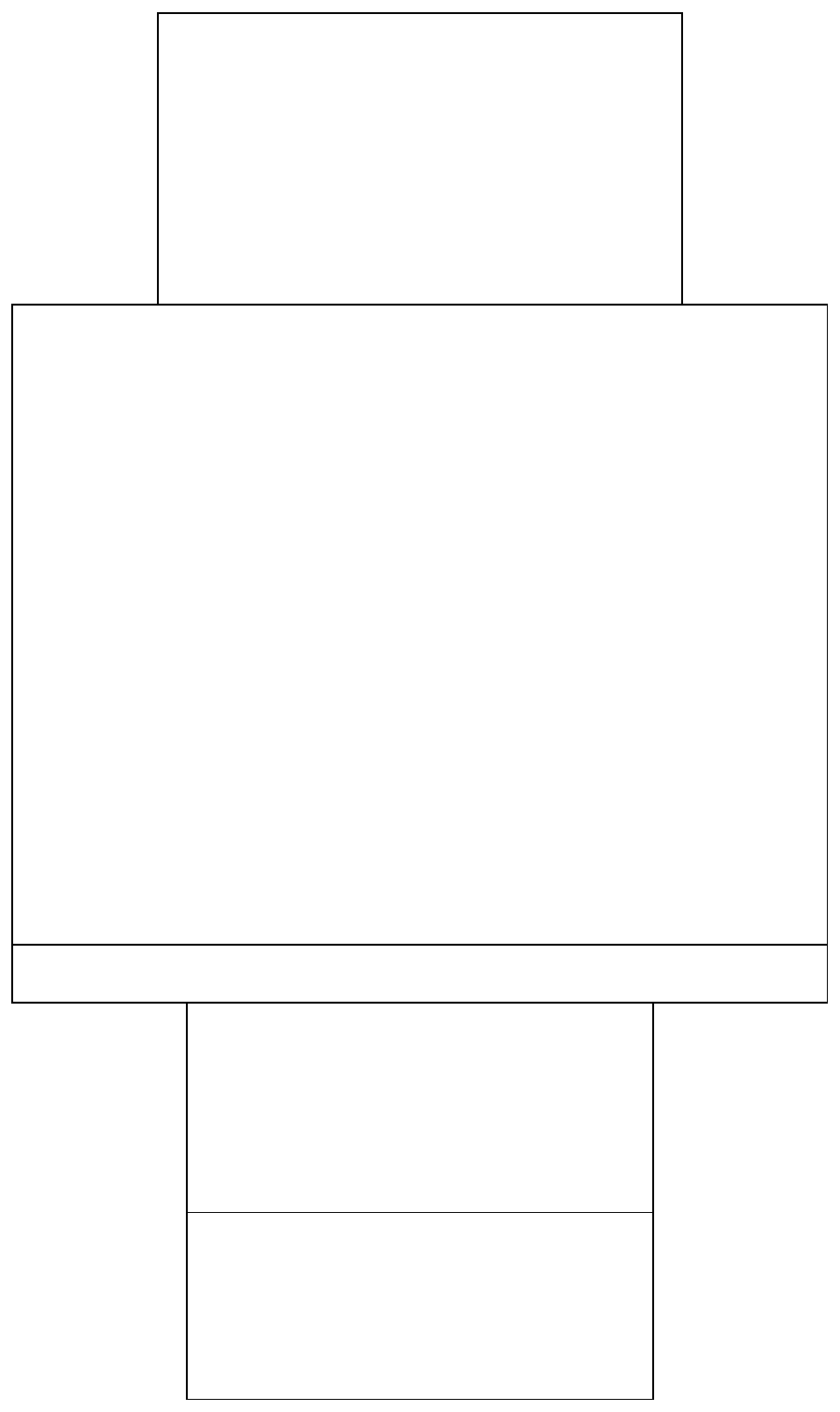

[0030] see Figure 1-21 As shown, a high-pressure water pump includes a cylinder body 1, and the right end of the cylinder body 1 is provided with a first piston hole 51, a second piston hole 52, and a third piston hole at regular intervals with the axis of the cylinder body 1 as the center. 53. The fourth piston hole 52, the first piston hole 51 is slidably connected with the first plug body 5a, the second piston hole 52 is slidably connected with the second plug body 5b, and the third piston hole 53 is slidably connected with the first plug body 5a. Three plug bodies 5c, the fourth plug body 5d is slidably connected in the fourth piston hole 52, the right end cover 6 is fixedly installed on the right end of the cylinder body 1, and the right end cover 6 is provided with a motor driven by the first plug body 5a. The first water pump assembly, the second water pump assembly driven by the second plug body 5b, the third water pump assembly driven by the third plug body 5c, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com