Leaning type arch center film structure

A membrane structure and leaning technology, applied in the field of structural frames, can solve the problems of high risk factor, high anti-corrosion cost, large amount of high-altitude work, etc., and achieve the effects of simple construction process, short construction period and low steel content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

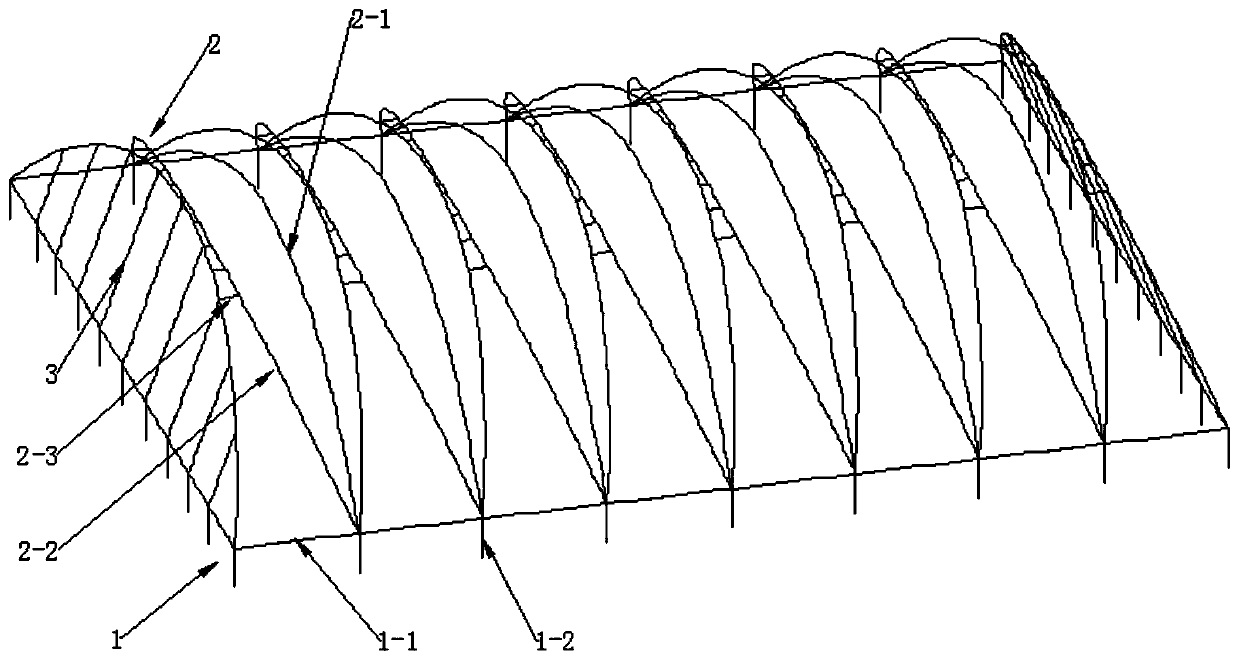

[0016] Such as figure 1 A reclining arch membrane structure is shown, which includes a bottom steel structure support 1 and several sets of top frame structures 2, and several sets of top frame structures 2 are evenly installed above the bottom steel structure support 1; near the left and right sides A number of side steel cables 3 are arranged between the top frame structure 2 at the edge and the bottom steel structure support 1 close to the left and right edges;

[0017] The support of the bottom steel structure 1 includes several columns 1-2 arranged in a rectangle, and horizontal steel cables 1-1 are arranged between the tops of adjacent columns 1-2;

[0018] The top frame structure 2 includes two leaning arch ribs 2-2 arranged symmetrically to each other and several connecting beams 2-3 arranged between the two leaning arch ribs; the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com