Yarn-dyed spiral towel fabric and preparation method thereof

A towel and fabric technology, applied in the direction of fabric, fabric surface trimming, fabric kneading/softening, etc., can solve the problems of bulkiness and poor air permeability, easy shaving, complicated and tedious preparation process, etc., and achieves a strong three-dimensional appearance, The effect of not easy hair removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

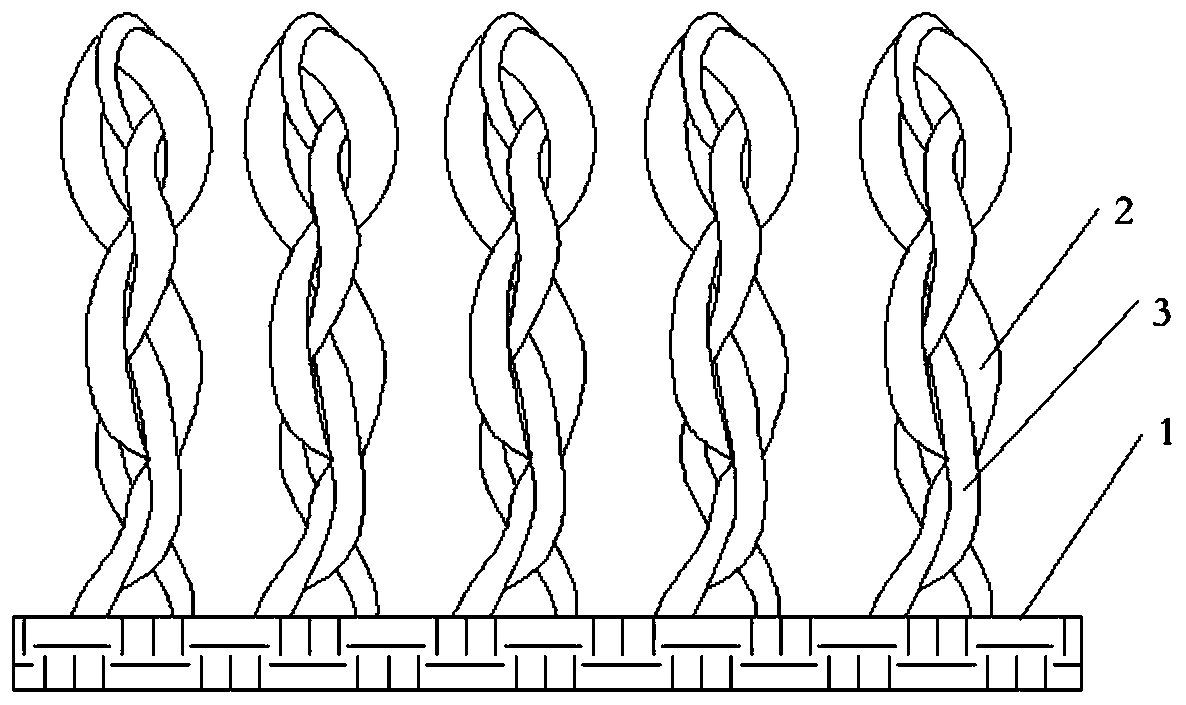

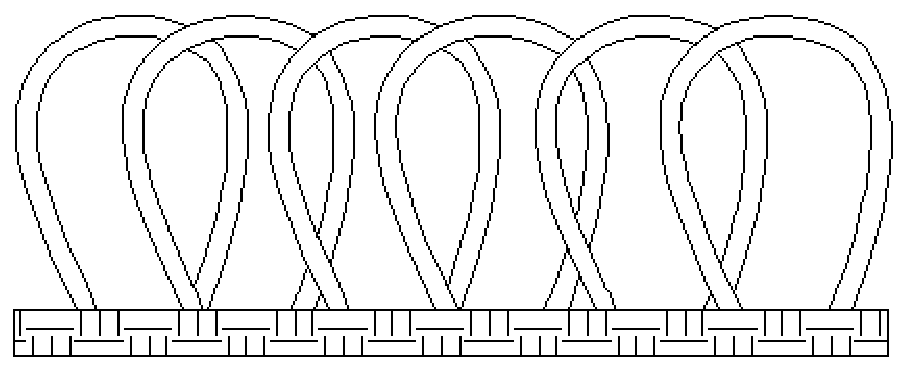

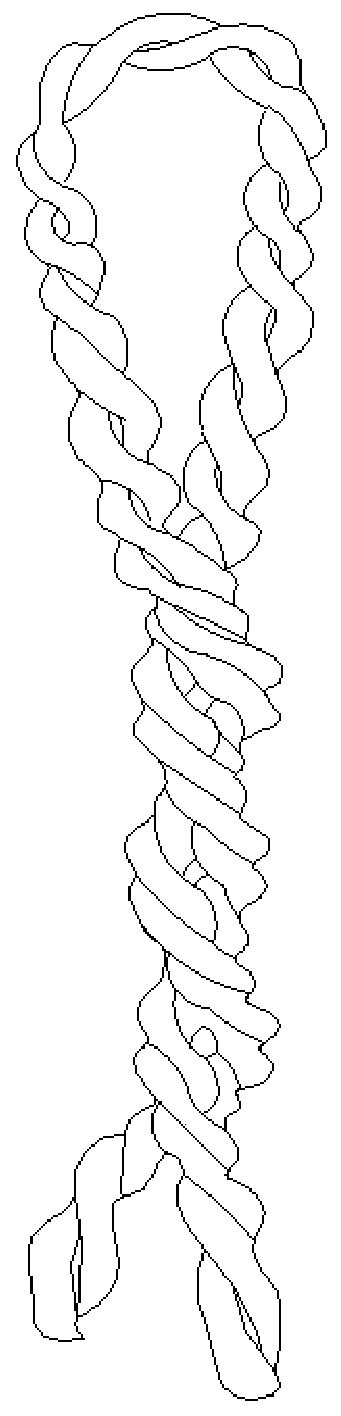

[0022] Embodiment 1: a kind of method for preparing yarn-dyed spiral towel, comprises the following steps:

[0023] S1. Carry out yarn-dyed towel weaving, the wool warp and ground warp of weaving the towel fabric are respectively interwoven with the weft yarn to form a towel fabric gray cloth with spiral pile loops; the wool warp adopts two kinds of 18.2tex single yarns of different colors to ply, The single yarn twist is 86 twists / 10 cm, and the ply twist is 55 twists / 10 cm; the length of the spiral pile is 1.24 cm, and single yarns of different colors are used for plying according to the required colors.

[0024] The ground warp 1 adopts 29.2tex*2 plied yarn, the ground warp density is 105 threads / 10cm, the weft yarn adopts 36.4tex single yarn, and the weft density is 175 threads / 10cm.

[0025] S2. Combing and softening the gray towel fabric in step S1;

[0026] S3. Washing the carded and softened towel fabric gray cloth in step S2 to obtain a finished towel fabric.

[002...

Embodiment 2

[0029] Embodiment 2: a kind of method for preparing yarn-dyed spiral towel, comprises the following steps:

[0030] S1. Carry out yarn-dyed towel weaving, the wool warp and ground warp of weaving the towel fabric are respectively interwoven with the weft yarn to form a towel fabric gray cloth with spiral piles; the wool warp 2 adopts two kinds of 18.2tex single yarns of different colors to ply , the single yarn twist is 88 twists / 10 centimeters, and the ply twist is 60 twists / 10 centimeters; the length of the spiral pile is 1.3 cm, and single yarns of different colors are used for plying according to the required color.

[0031] The ground warp 1 adopts 29.2tex*2 plied yarn, the ground warp density is 110 threads / 10cm, the weft yarn adopts 36.4tex single yarn, and the weft density is 180 threads / 10cm.

[0032] S2. Combing and softening the gray towel fabric in step S1;

[0033] S3. Washing the carded and softened towel fabric gray cloth in step S2 to obtain a finished towel f...

Embodiment 3

[0036] Embodiment 3: a kind of method for preparing yarn-dyed spiral towel, comprises the following steps:

[0037] S1. Carry out yarn-dyed towel weaving, the wool warp and ground warp of weaving the towel fabric are respectively interwoven with the weft yarn to form a towel fabric gray cloth with spiral piles; the wool warp 2 adopts two kinds of 18.2tex single yarns of different colors to ply , the single yarn twist is 90 twists / 10 centimeters, and the ply twist is 65 twists / 10 centimeters; the length of the spiral pile is 1.4 cm, and single yarns of different colors are used for plying according to the required color.

[0038] The ground warp 1 adopts 29.2tex*2 plied yarn, the ground warp density is 120 threads / 10cm, the weft yarn adopts 36.4tex single yarn, and the weft density is 190 threads / 10cm.

[0039] S2. Combing and softening the gray towel fabric in step S1;

[0040] S3. Washing the carded and softened towel fabric gray cloth in step S2 to obtain a finished towel f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com