Fluorescent gold nano-cluster as well as preparation method and application thereof

A fluorescent gold nanometer and fluorescent technology, applied in the field of fluorescent gold nanoclusters and its preparation, can solve the problems of narrow application range, cumbersome operation, and poor specificity, and achieve the effects of strong sensitivity, high detection efficiency, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: Preparation of Xylanase-Au NCs

[0040] Take xylanase and add it into ultrapure water to prepare 0.25mM xylanase solution, and prepare 25mM HAuCl 4 The aqueous solution is added to the above-mentioned xylanase solution, so that the xylanase and HAuCl 4 The molar mass ratio is 1:1. After fully mixing with a vortex for 5 minutes, add an aqueous solution of 1M NaOH to make the pH of the mixed solution 12, and then mix again with a vortex for 5 minutes. The Eppendorf tube was placed in a 37°C water bath for 12 hours in the dark to obtain a gold nanocluster polymer with a concentration of 0.16mM, centrifuged at 5,000rpm for 10min, and the supernatant was stored in a 4°C refrigerator in the dark for future use.

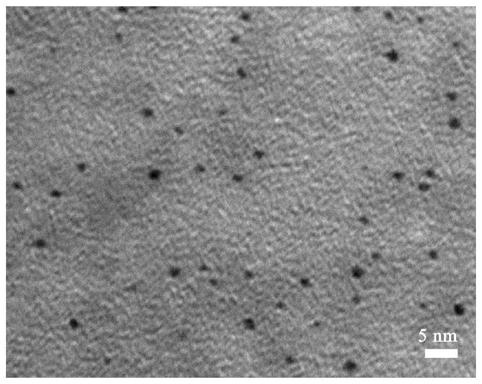

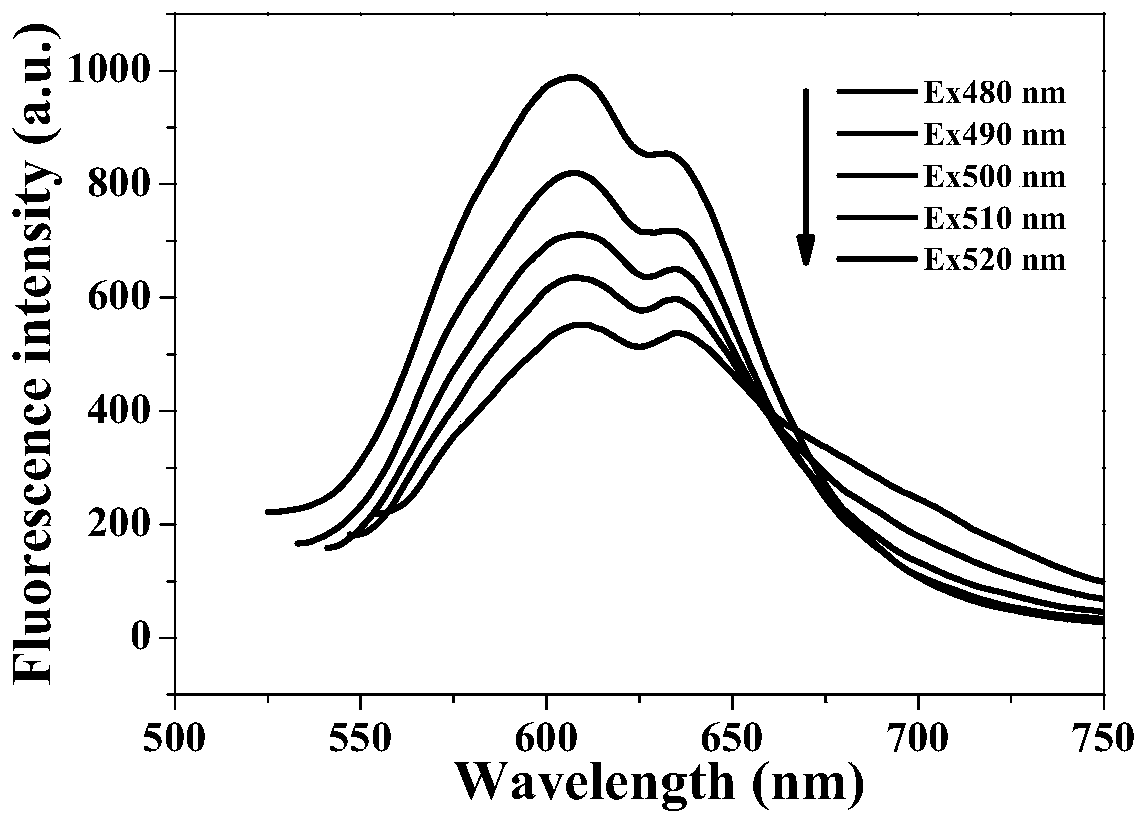

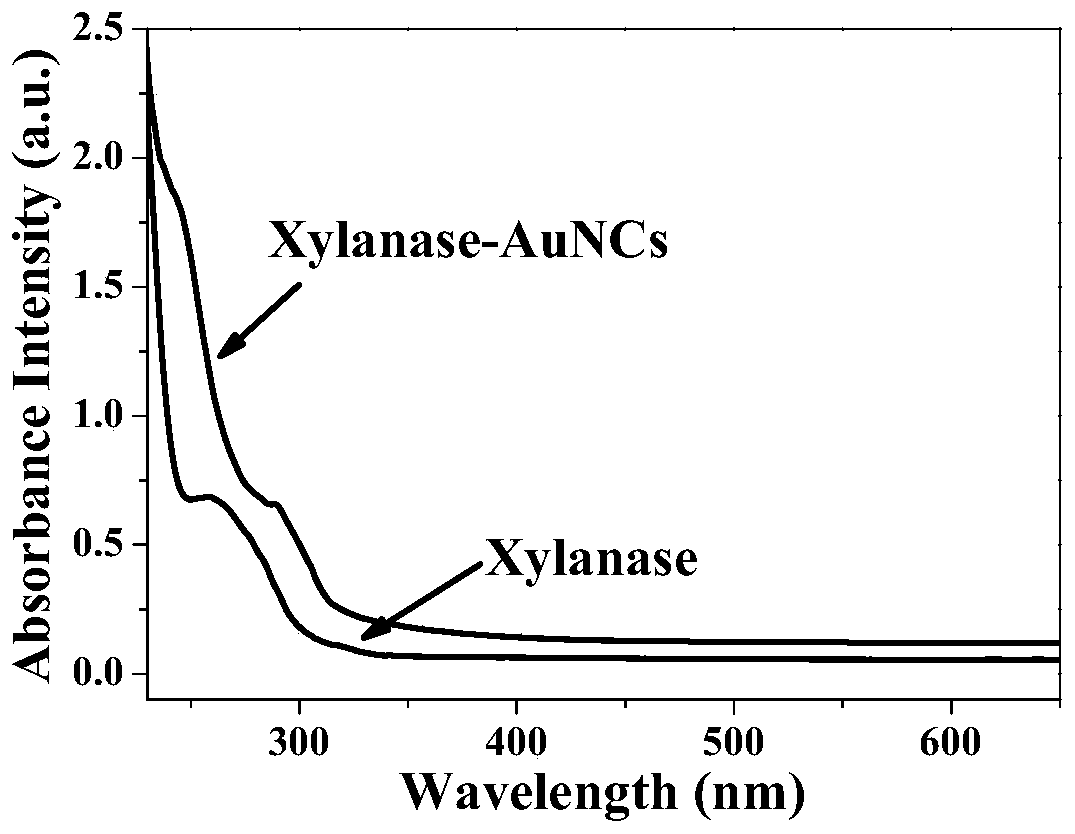

[0041] The transmission electron microscope picture (TEM) of present embodiment gold nanocluster is as figure 1 shown, from figure 1 It can be seen that the size of gold nanoclusters is uniform and dispersed, and the particle size is less than 5nm; ...

Embodiment 2

[0046] Embodiment 2: Preparation of Xylanase-Au NCs

[0047] Take xylanase and add it into ultrapure water to prepare 1mM xylanase solution, and prepare 25mM HAuCl 4 The aqueous solution is added to the above-mentioned xylanase solution, so that the xylanase and HAuCl 4 The molar mass ratio is 0.8:1. After fully mixing with a vortex for 5 minutes, add 1M NaOH solution to make the pH of the mixed solution 10, and then mix with a vortex for 5 minutes again. The Eppendorf tube was placed in a water bath at 37°C for 12 hours in the dark to obtain polymers of gold nanoclusters, centrifuged at 5,000 rpm for 10 minutes, and the supernatant was stored in a refrigerator at 4°C in the dark for future use.

Embodiment 3

[0048] Embodiment 3: Preparation of Xylanase-Au NCs

[0049] Take xylanase and add it into ultrapure water to prepare 1mM xylanase solution, and prepare 25mM HAuCl 4 Add the aqueous solution of xylanase to the above xylanase solution, so that the xylanase and HAuCl 4 The molar mass ratio is 1.5:1. After fully mixing with a vortex for 5 minutes, add 1M NaOH solution to make the pH of the mixed solution 12, and then mix again with a vortex for 5 minutes. The Eppendorf tube was placed in a water bath at 30°C for 24 hours in the dark to obtain polymers of gold nanoclusters, centrifuged at 5,000 rpm for 10 minutes, and the supernatant was stored in a refrigerator at 4°C in the dark for future use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com