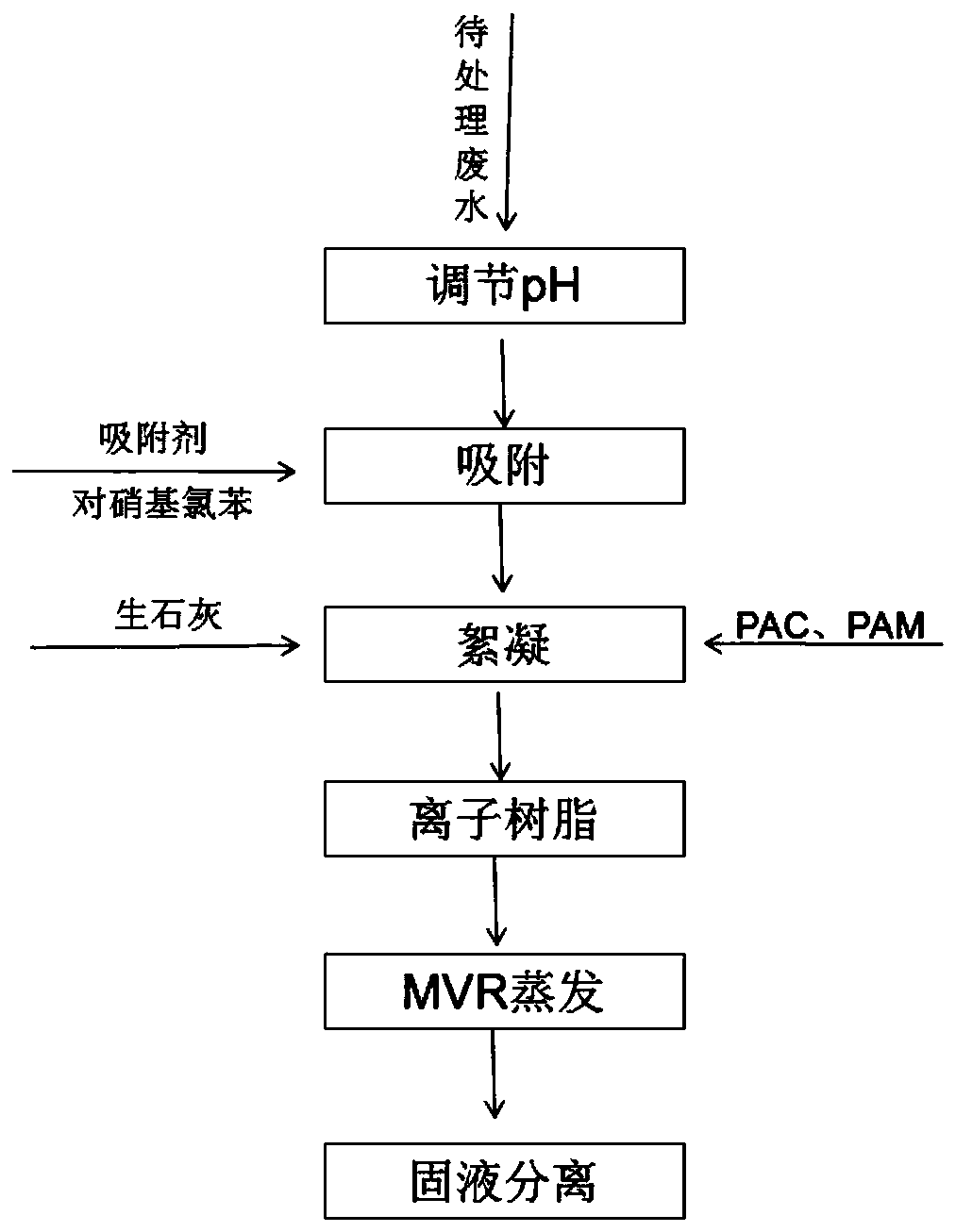

Treatment process of betaine production wastewater

A technology for treating process and producing wastewater, applied in water/sewage treatment, heating water/sewage treatment, adsorption water/sewage treatment, etc. Better processing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The concentration of trimethylamine in the betaine wastewater to be treated is 921mg / L, and the COD is 9803mg / L. First, acid solution is added to the wastewater to be treated to adjust the pH value to 3, and diatomite adsorbent 8mg / l and p-nitrogen Chlorobenzene 0.3mg / L, stirred and reacted at 35°C for 20min, solid-liquid separation was carried out after the reaction was completed; quicklime was added to the supernatant to adjust the pH value to 9, and then PAC and PAM 18mg / L were added for flocculation and sedimentation; The constant flow pump pumps the treated wastewater into the ion resin column for ion adsorption operation. The adsorption treatment time is 2.5 hours; the treated wastewater is sent to the MVR evaporator, and the evaporation concentration temperature is 110 ° C. When the solid content of the remaining liquid Stop evaporation when reaching 5%, then carry out solid-liquid separation, after processing finishes, the concentration of trimethylamine in the s...

Embodiment 2

[0025] The concentration of trimethylamine in the betaine wastewater to be treated is 1011mg / L, and the COD is 12385mg / L. Firstly, acid solution is added to the wastewater to be treated to adjust the pH value to 3.5, and clay adsorbent 9mg / l and p-nitrochlorobenzene are added. 1mg / L, stirring and reacting at 35°C for 15min, solid-liquid separation after the reaction is completed; add quicklime to the supernatant to adjust the pH value to 9, then add PAC and PAM 20mg / L for flocculation and sedimentation; use a constant flow pump The treated wastewater is pumped into the ion resin column for ion adsorption operation, and the adsorption treatment time is 2 hours; the treated wastewater is sent to the MVR evaporator, and the evaporation concentration temperature is 110°C. When the solid content of the remaining liquid reaches 8% Stop evaporation, and then carry out solid-liquid separation, after processing is finished, the concentration of trimethylamine in the solution is 18mg / L, ...

Embodiment 3

[0029] The concentration of trimethylamine in the betaine wastewater to be treated is 982mg / L, and the COD is 10321mg / L. Firstly, acid solution is added to the wastewater to be treated to adjust the pH value to 4, and clay adsorbent 9mg / l and p-nitrochlorobenzene are added. 1.2mg / L, stirred and reacted at 38°C for 25min, separated the solid and liquid after the reaction was completed; added quicklime to the supernatant, adjusted the pH value to 10, and then added PAC and PAM 25mg / L for flocculation and sedimentation; adopted constant flow The pump pumps the treated wastewater into the ion resin column for ion adsorption operation. The adsorption treatment time is 2 hours; the treated wastewater is sent to the MVR evaporator, and the evaporation concentration temperature is 110 ° C. When the solid content of the remaining liquid reaches 10 %, stop evaporation, and then carry out solid-liquid separation. After the treatment is completed, the concentration of trimethylamine in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com