Fixed bed reactor for catalytic reduction of hexavalent uranium by hydrazine nitrate, and application thereof

A fixed bed reactor and catalytic bed technology is applied in the field of reactor devices for reducing hexavalent uranium to generate tetravalent uranium, and can solve the problems of increasing solid waste, slow reaction process, catalyst deactivation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

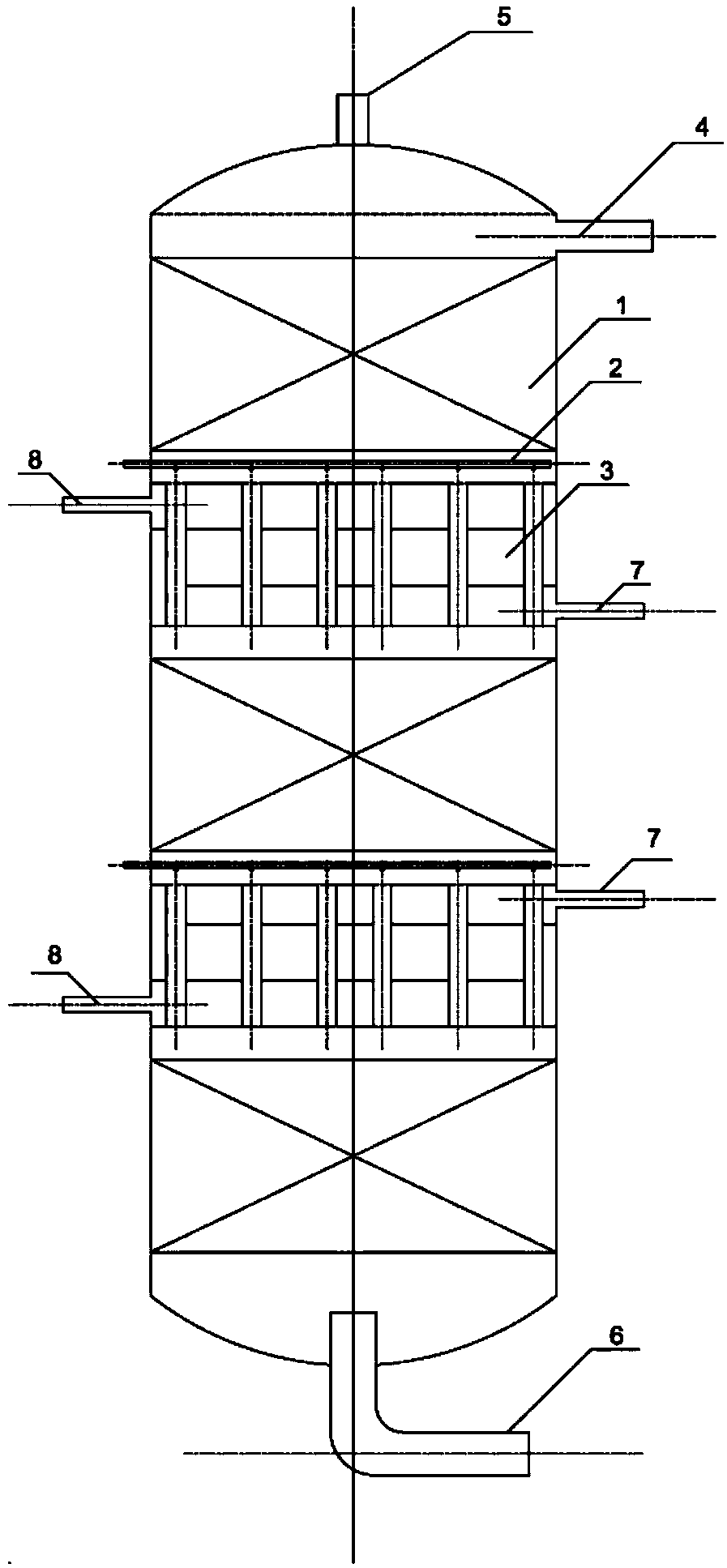

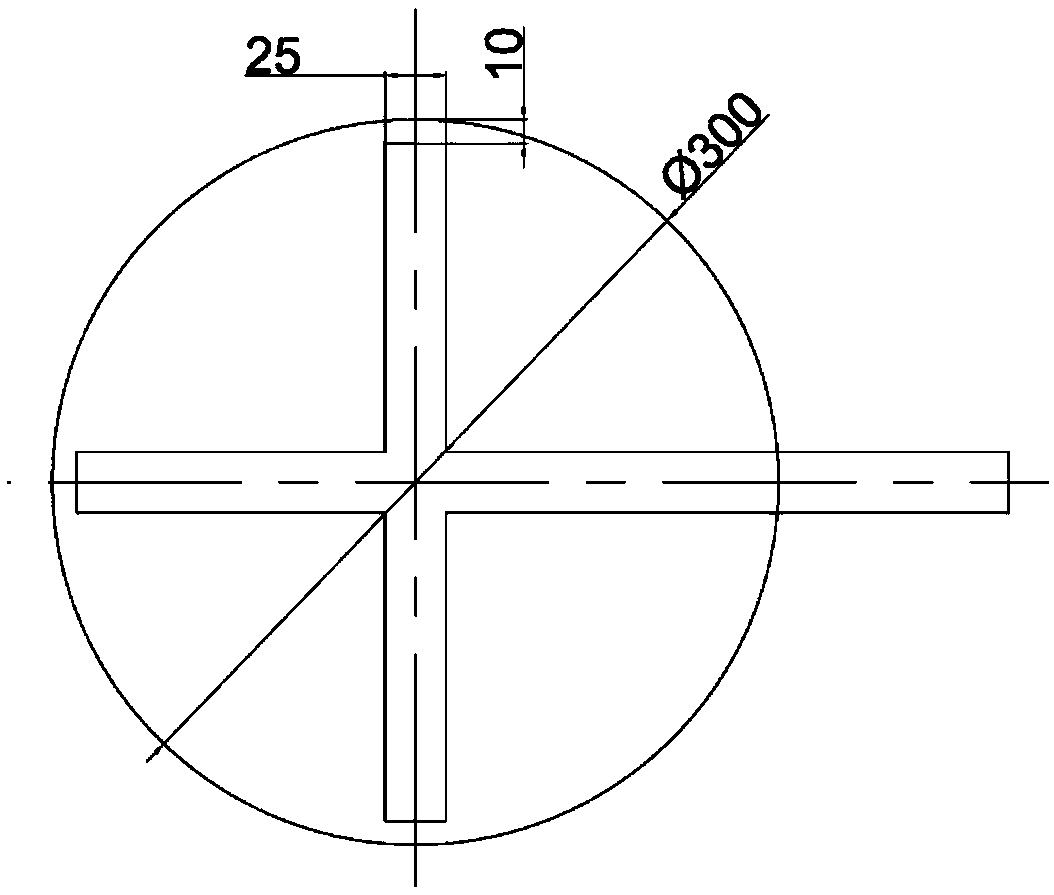

[0032] The reaction liquid processing capacity is 13.8kg / h, wherein the mass content of UO2(NO3)2 is 0.31, N2H5NO3 is 0.11, HNO3 content is 0.05 and H2O content is 0.54; the diameter of the reactor is 300x2mm, and the catalyst is loaded in three stages. The diameter of the particles is 5mm, the length of the catalytic bed of each reactor is 300mm, the diameter of the top and bottom of each catalytic bed is 10mm, and the length is 50mm. The diameter of the heat exchange tube is 30x1.5mm, and the heat exchange tube is distributed in a regular triangle The quantity is 20, and the length of the heat exchange tube is 50cm; the acid regulating distributor is composed of figure 2The composition of the cross structure shown is a stainless steel pipe with a diameter of 25x1.5mm, the diameter of the opening is 1.0mm, the hole spacing is 20mm, the flow rate of 50% nitric acid is 0.5kg / h; the reaction liquid inlet temperature is 40 degrees, and the cooling water inlet The outlet temperat...

Embodiment 2

[0034] Compared with Example 1, the difference is that the length of each catalyst section is 400 mm, which is due to the increase in the length of the catalyst, and the transition consumption of hydrazine nitrate makes the tetravalent uranium generated by the reaction further oxidized to hexavalent uranium in the later stage of the reaction, and the hexavalent uranium is converted into The rate becomes 75%, the export tetravalent uranium content is 150g / L, and the conversion rate of hydrazine nitrate is 95%;

Embodiment 3

[0036] Compared with Example 1, the difference is that the number of heat exchange tubes is 50, the average temperature of the reactor is 45 degrees, the conversion rate of hexavalent uranium is 70%, the content of tetravalent uranium in the outlet is 140g / L, and the conversion rate of hydrazine nitrate is 60%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com