Desferoxamine slow-release microbubble modified composite pore electrospun scaffold and preparation method thereof

An electrospinning and deferrioxamine technology, which is applied in the field of composite pore size electrospinning scaffolds modified by deferrioxamine sustained-release microbubbles and their preparation, can solve the problems of few related research reports on the release of activators, and achieve improved release. Effects of Features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

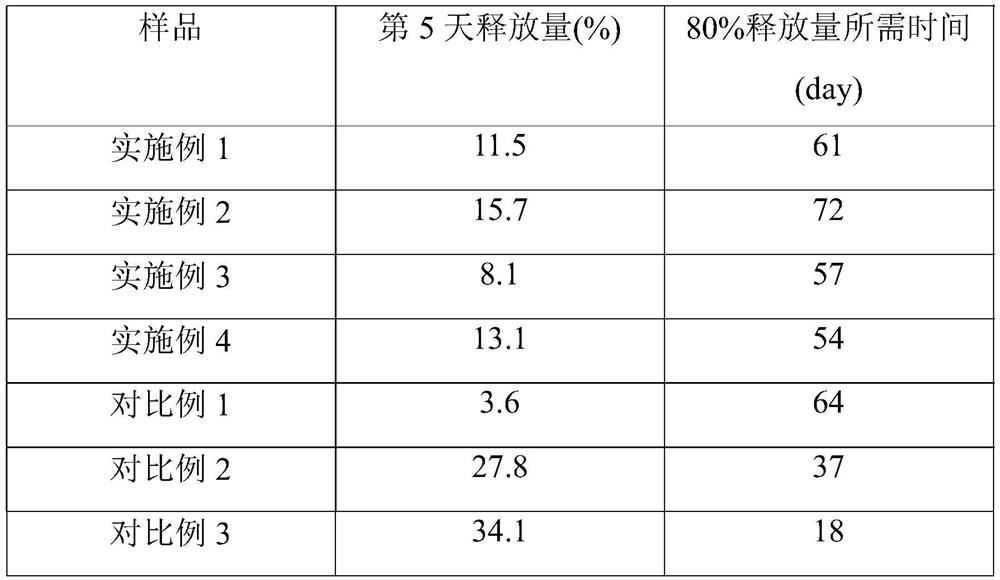

Examples

Embodiment 1

[0028] 1) Preparation of deferoxamine sustained-release microbubbles

[0029] Add 8g lactide, 2g glycolide, 1g polyethylene glycol 2000 to the polymerization tube, then add 0.5g of 0.3% stannous octoate in dichloromethane solution as a catalyst, and heat the polymerization tube to 150°C under vacuum to mix The material is melted and mixed uniformly, and kept for 8h. After natural cooling, it was dissolved in acetone, precipitated and washed with water to obtain a polymer as a shell material. The hydrophilicity test contact angle of the polymer prepared above was 30°, the viscosity was 1.2, and the elongation at break was 4.5%.

[0030] Dissolve 0.5 g of deferoxamine in 10 mL of water as the inner water phase, then dissolve 5 g of the polymer in 100 mL of ethyl acetate as the oil phase, and disperse the inner water phase in the oil phase by fully stirring to obtain a W / O type emulsion; 10g of PVA and 25g of NaCl were dissolved in 500mL of water as the outer water phase, and t...

Embodiment 2

[0036] 1) Preparation of deferoxamine sustained-release microbubbles: This procedure is the same as that in Example 1.

[0037] 2) Preparation of Deferrioxamine Sustained-release Microbubbles Modified Electrospinning Scaffolds

[0038] The core solution of electrospinning is composed of deferoxamine sustained-release microbubbles, type I collagen, and hexafluoroisopropanol, the mass content of deferoxamine sustained-release microbubbles is 10%, and the mass content of type I collagen is 5%; electrospinning The shell liquid of the silk is composed of hydroxyapatite, type I collagen and hexafluoroisopropanol, the mass content of hydroxyapatite is 15%, and the mass content of type I collagen is 15%; prepared by coaxial electrospinning method, wherein , the electrostatic high voltage was 50 kV, the receiving distance was 200 mm, and the electrospinning rate was 0.05 ml / min, to prepare a deferoxamine sustained-release microbubble modified electrospinning scaffold.

[0039] 3) Prep...

Embodiment 3

[0042] 1) Preparation of deferoxamine sustained-release microbubbles: This procedure is the same as that in Example 1.

[0043] 2) Preparation of Deferrioxamine Sustained-release Microbubbles Modified Electrospinning Scaffolds

[0044] The core solution of electrospinning is composed of deferoxamine sustained-release microbubbles, type I collagen and hexafluoroisopropanol, the mass content of deferoxamine sustained-release microbubbles is 1%, and the mass content of type I collagen is 15%; electrospinning The shell liquid of the silk is composed of hydroxyapatite, type I collagen and hexafluoroisopropanol, the mass content of hydroxyapatite is 5%, and the mass content of type I collagen is 5%; prepared by coaxial electrospinning method, wherein , the electrostatic high voltage was 1 kV, the receiving distance was 50 mm, and the electrospinning rate was 0.2 ml / min, to prepare a deferoxamine sustained-release microbubble modified electrospinning scaffold.

[0045] 3) Preparatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com