Crane wheel rail wear monitoring method based on residual stress influence interval correction

A residual stress and crane technology, which is applied in the field of crane wheel-rail wear monitoring based on the correction of residual stress influence interval, can solve the problems of aggravating the degree of wear between the wheel and rail, potential safety hazards, and not fully considering the compound action mechanism of the degree of wheel-rail wear, etc. achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

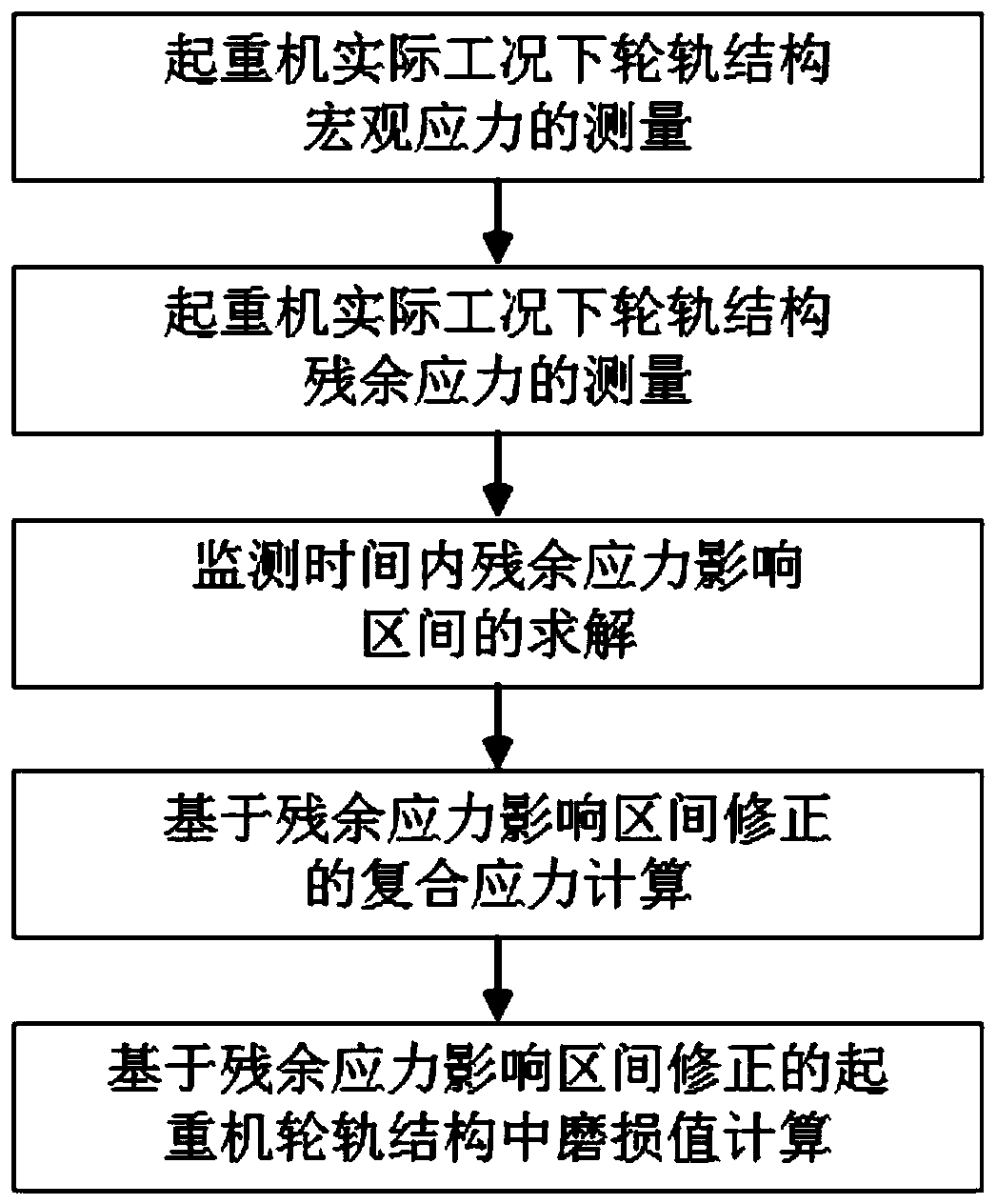

[0026] Please refer to figure 1 , the present invention is a crane wheel-rail wear monitoring method based on residual stress influence interval correction, and the method comprises the following steps:

[0027] S1. Measurement of the macroscopic stress of the wheel-rail structure under the actual working conditions of the crane:

[0028] Firstly, the finite element analysis model of the crane wheel-rail structure is established in the finite element analysis software ANSYS, and the grid is divided by using the adaptive mode, and then the load and constraint conditions of the working condition are imported into the pre-processing module. Start the post-processing process, determine the vulnerable parts of the crane wheel-rail structure in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com