Method and system for monitoring and adjusting cooking appliances

An adjustment method and technology for cooking appliances, which are applied to household stoves, heating methods, cooking utensils, etc., can solve the problems of electronic equipment, such as harsh requirements for high temperature resistance, difficult to achieve, and easy to be affected by indoor light and lampblack.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

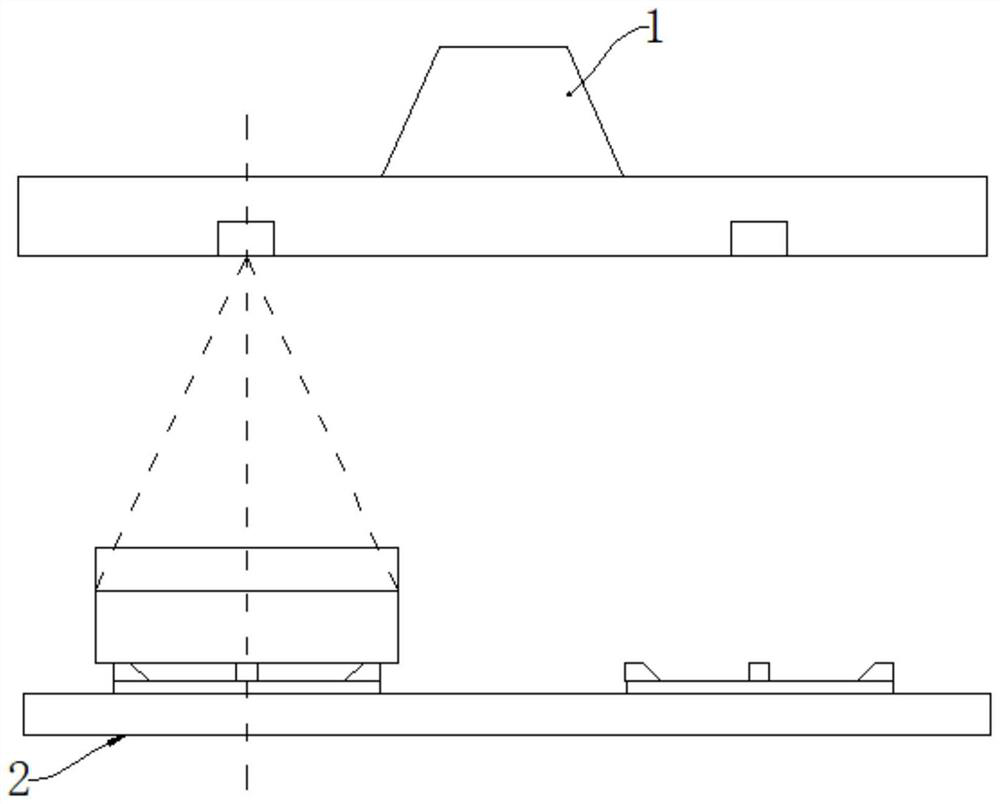

[0089] see Figure 1 to Figure 8 As shown, a method for monitoring and adjusting a cooktop in this embodiment includes the following steps:

[0090] Send out radar transmission signals to the cooking vessel on the stove in real time;

[0091] Receive the reflected signal reflected by the cooking container, liquid level or / and food in real time;

[0092] Obtain the liquid level state information of the cooking container according to the reflected signal;

[0093] Adjust the heating power of the cooktop according to the liquid level information.

[0094] Preferably, adjusting the heating power of the cooker according to the liquid level state information is specifically: judging whether overflow or dry pot occurs, and if so, lowering the heating power of the cooker or setting the heating power of the cooker to zero.

[0095] Preferably, the liquid level state information of the cooking container is obtained according to the reflected signal, specifically:

[0096] Extract th...

Embodiment 2

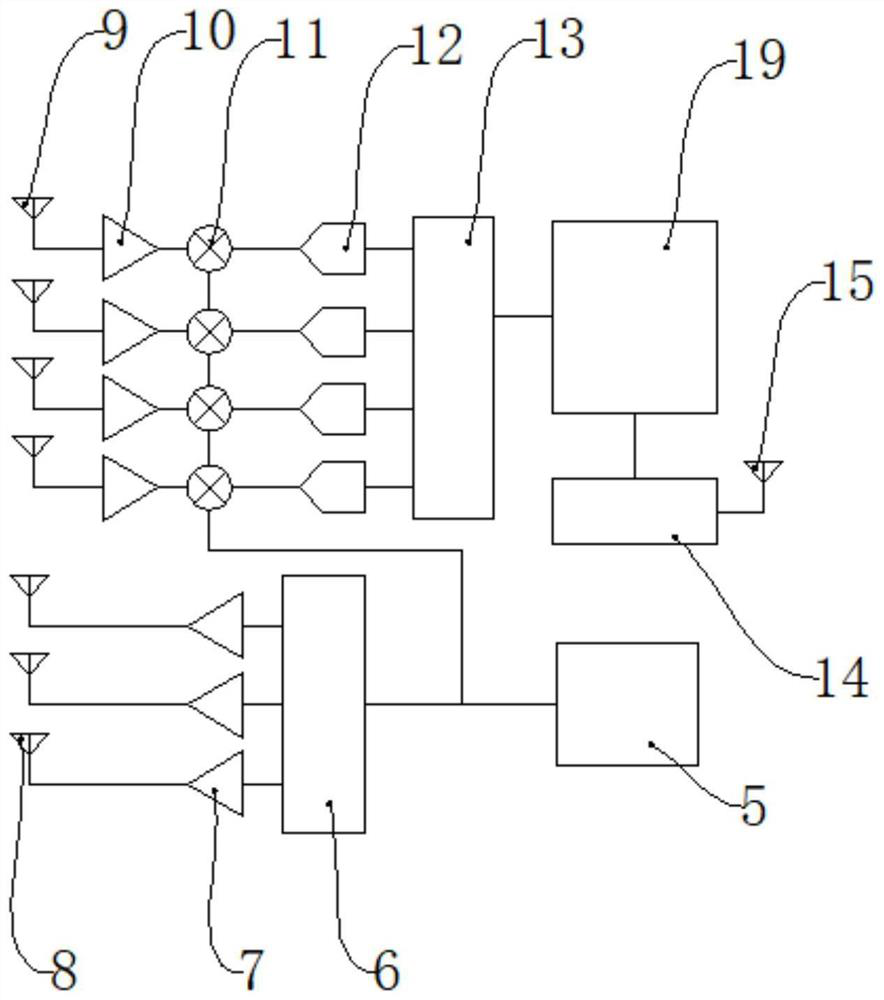

[0146] see Figure 9 As shown, a cooker monitoring and adjustment system includes a range hood 1 and an intelligent terminal 4, and the range hood 1 is connected in communication with the intelligent terminal 4;

[0147] The range hood 1 includes:

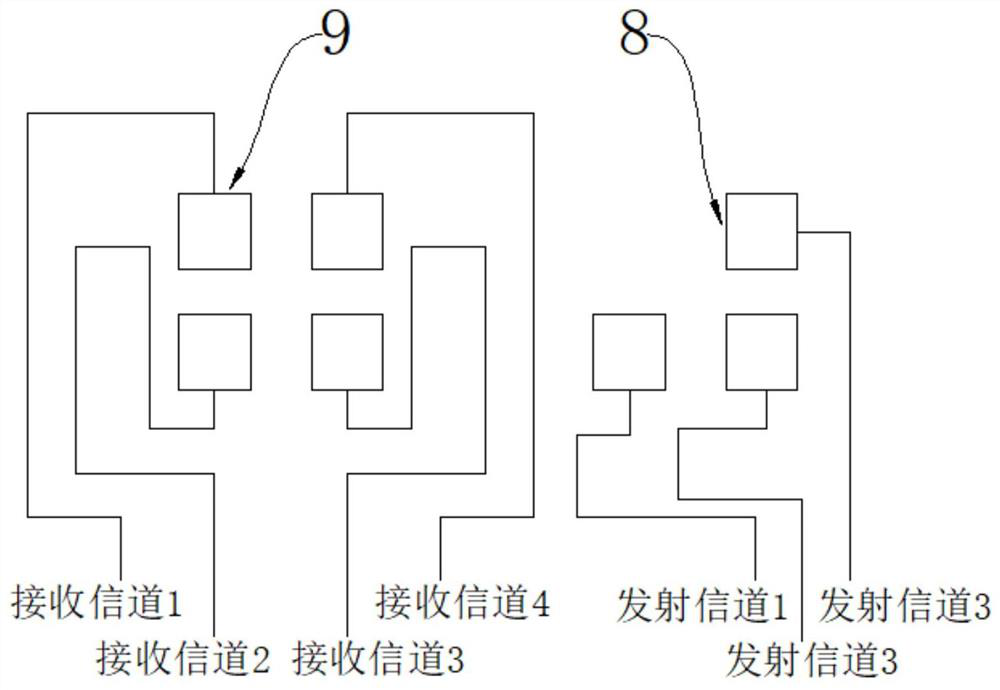

[0148] The radar transmitting module is used to send the radar transmitting signal to the cooking container on the stove 2 in real time;

[0149] The reflection receiving module is used to receive the reflection signal reflected by the cooking container, the liquid level or / and the food in real time;

[0150] a signal processing module, used for obtaining the liquid level state information of the cooking container according to the reflected signal;

[0151] a data processing module for judging whether the heating power of the cooker 2 needs to be adjusted according to the liquid level state information;

[0152] a feedback adjustment module for sending out an adjustment signal for adjusting the heating power of the cooktop 2;

...

Embodiment 3

[0157] see Figure 10 As shown, a monitoring and adjustment system for a range hood includes a range hood 1 and a range hood 2, and the range hood 1 is connected in communication with the range hood 2;

[0158] The range hood 1 includes:

[0159] The radar transmitting module is used to send the radar transmitting signal to the cooking container on the stove 2 in real time;

[0160] The reflection receiving module is used to receive the reflection signal reflected by the cooking container, the liquid level or / and the food in real time;

[0161] a signal processing module, used for obtaining the liquid level state information of the cooking container according to the reflected signal;

[0162] a data processing module for judging whether the heating power of the cooker 2 needs to be adjusted according to the liquid level state information;

[0163] a feedback adjustment module for sending out an adjustment signal for adjusting the heating power of the cooktop 2;

[0164] Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap