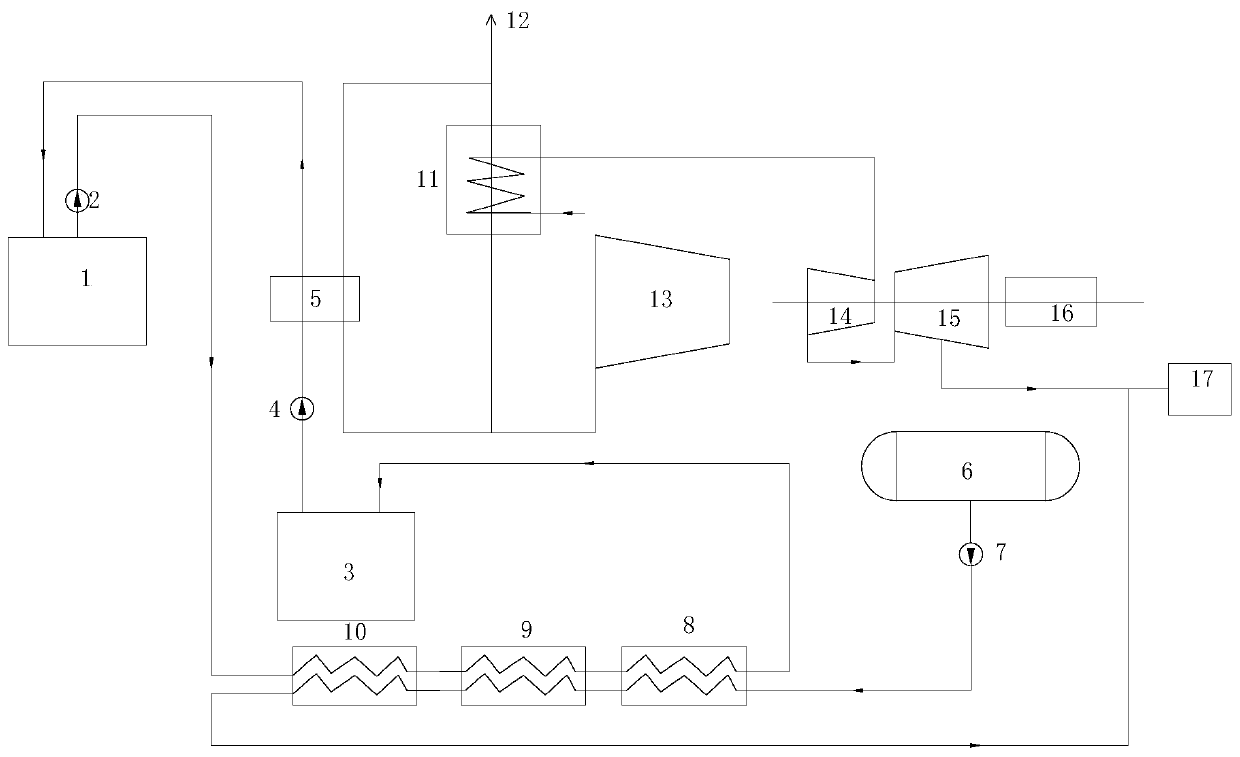

Thermoelectric decoupling system and method for gas turbine cogeneration unit

A technology for cogeneration units and gas turbines, which is applied in the field of thermo-decoupling systems, can solve problems such as failure to utilize natural gas in cascade, and achieve the effects of reducing natural gas consumption, avoiding high energy consumption, and reducing steam costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] Taking a 9F gas turbine unit as an example, under rated working conditions, the generating power is 340MW, the temperature of the flue gas discharged from the gas turbine is 604°C, the flow rate of flue gas is 2355t / h, the enthalpy of high-temperature flue gas is 653kJ / kg, and the rated heating flow 100t / h, heating parameters of 1.7MPa, 260°C, steam enthalpy of 3010kJ / kg, design a set of capacity of 950MWh gas turbine flue gas heating molten salt heat storage peak-shaving system, the single-time steam production of this system is 1200t, The produced steam is merged into the industrial steam supply pipeline.

[0040] Among them, the heat exchange area of the flue gas molten salt heat exchanger is 1800㎡, the molten salt steam generator is 1200㎡, the molten salt steam superheater is 60㎡, the design flow rate of the low-temperature and high-temperature molten salt pump is 650t / h, and the design flow rate of the water pump is 100t / h. The head is 80m, the radius of the low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com