A New Reaming Tool While Drilling

A new type of drilling-while-drilling and tool technology, which is applied in the direction of drill bits, earthwork drilling, drilling equipment, etc., can solve the problems of increased drilling costs, fast wear, and limited diameter expansion, and achieves reliable hydraulic work, simple operation, and extended The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

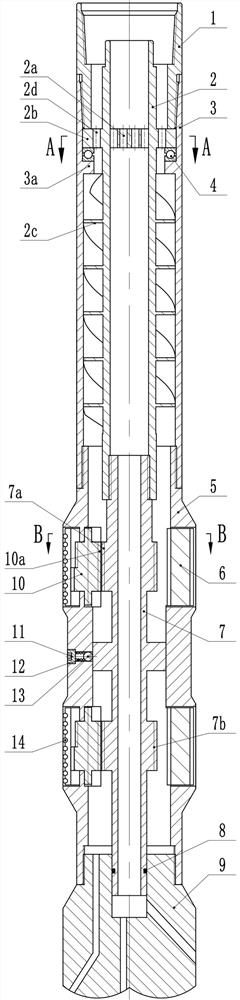

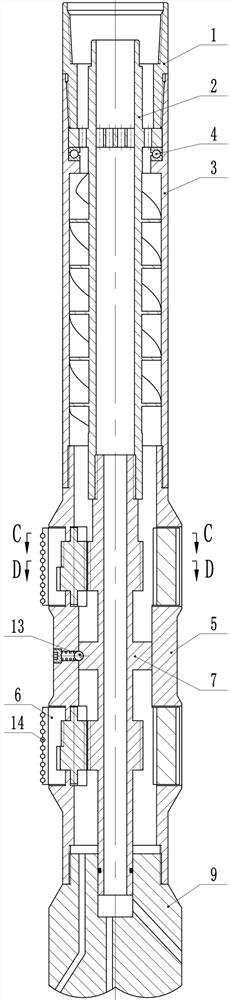

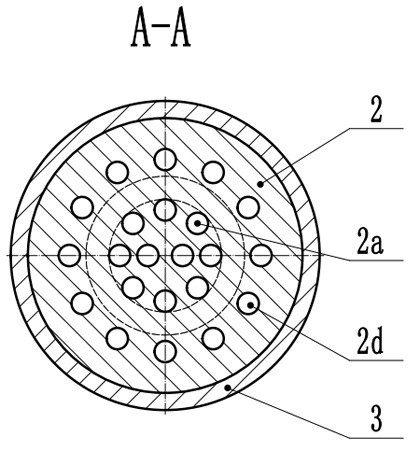

[0015] Such as Figure 1 to Figure 7 As shown, a new tool for reaming while drilling consists of an upper joint, a screw shaft, an upper casing, a thrust bearing, a lower casing, a blade, a gear shaft, a sealing ring, a drill bit, a rotating support, a pressure cap, a spring, Composed of positioning balls and PDC teeth, its features are: the lower end of the upper joint 1 is threadedly connected to the upper end of the upper housing 3, the upper part of the inner cavity of the upper housing 3 is provided with a bearing support seat 3a, and the thrust bearing 4 is placed on the upper surface of the bearing support seat 3a , the screw shaft 2 is placed in the upper casing 3, the outer surface of the middle part of the screw shaft 2 is provided with a helical wing 2c, the helical wing 2c and the inner wall of the upper casing 3 adopt a clearance fit, and the upper outer surface of the helical shaft 2 is provided with a circular hanging protrusion The table 2b and the suspension b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com