A construction method for steel box girder unloading

A construction method and technology of steel box girders, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems that cannot be realized, and achieve the effects of safety assurance, easy operation, and reduction of time for high-altitude operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

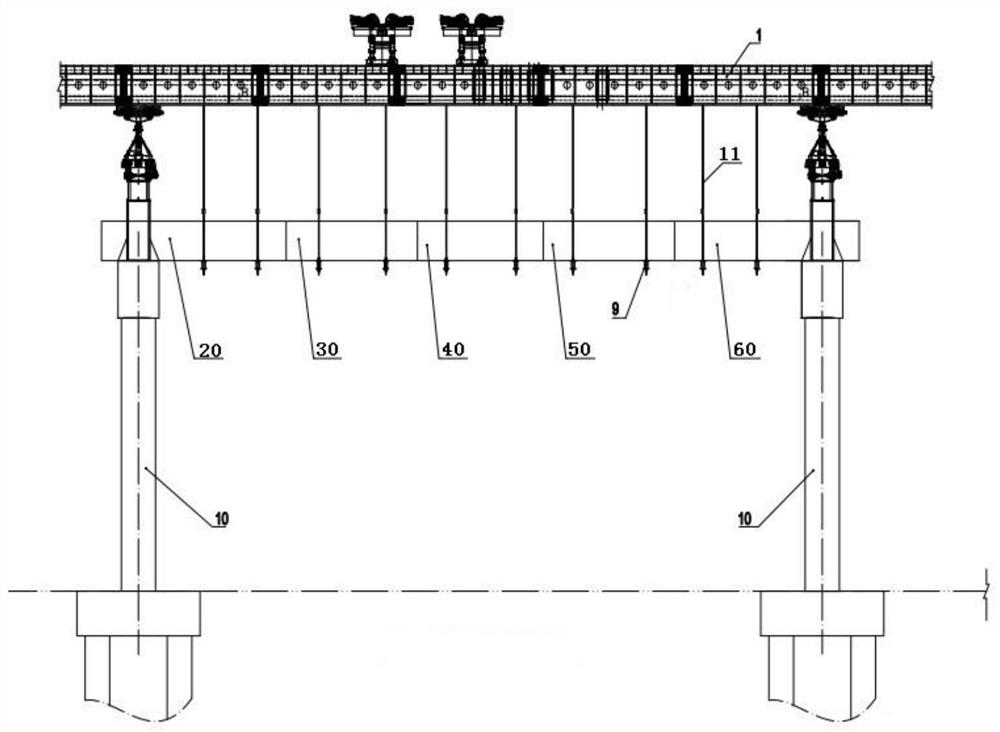

[0055] like figure 1 , figure 2 FIG, uninstall the steel box girder construction method, comprising the steps of:

[0056] Step 1, 3 on the pre-unloading means erecting machine section 1, section 1 moves to the erecting machine 10 pier;

[0057] Step 2, the segment erecting machine 1 is mounted on the unloading apparatus 3;

[0058] Step 3, lifting steel box girder section 12;

[0059] Step 4, docking boom 4 and the lower boom 6, the suspension steel box girder section 12;

[0060] Step 5, assembled and welded to steel box girder section 12, is formed across the entire steel box girder and unloading;

[0061] Step 6, 9 separate steel box girder and the bottom surface of a span of the balance beam.

[0062] Further, step 1, comprising the steps of:

[0063] Step 1.1, unloading device 3 is assembled, an upper sleeve unloading device 3 (not shown), a lower casing (not shown), locking means (not shown), cock type valve (not shown in FIG. ), and the upper casing sleeve is provided in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com