Long-life air compressor oil composition

A technology of air compressor oil and composition, which is applied in the direction of lubricating composition and petroleum industry, etc. It can solve the problems of carbon deposition and poor solvency of paint film, large expansion of sealing elastomer materials, and poor hydrolysis stability of synthetic esters, etc., to achieve Excellent anti-oxidation performance, lower temperature and oil temperature, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

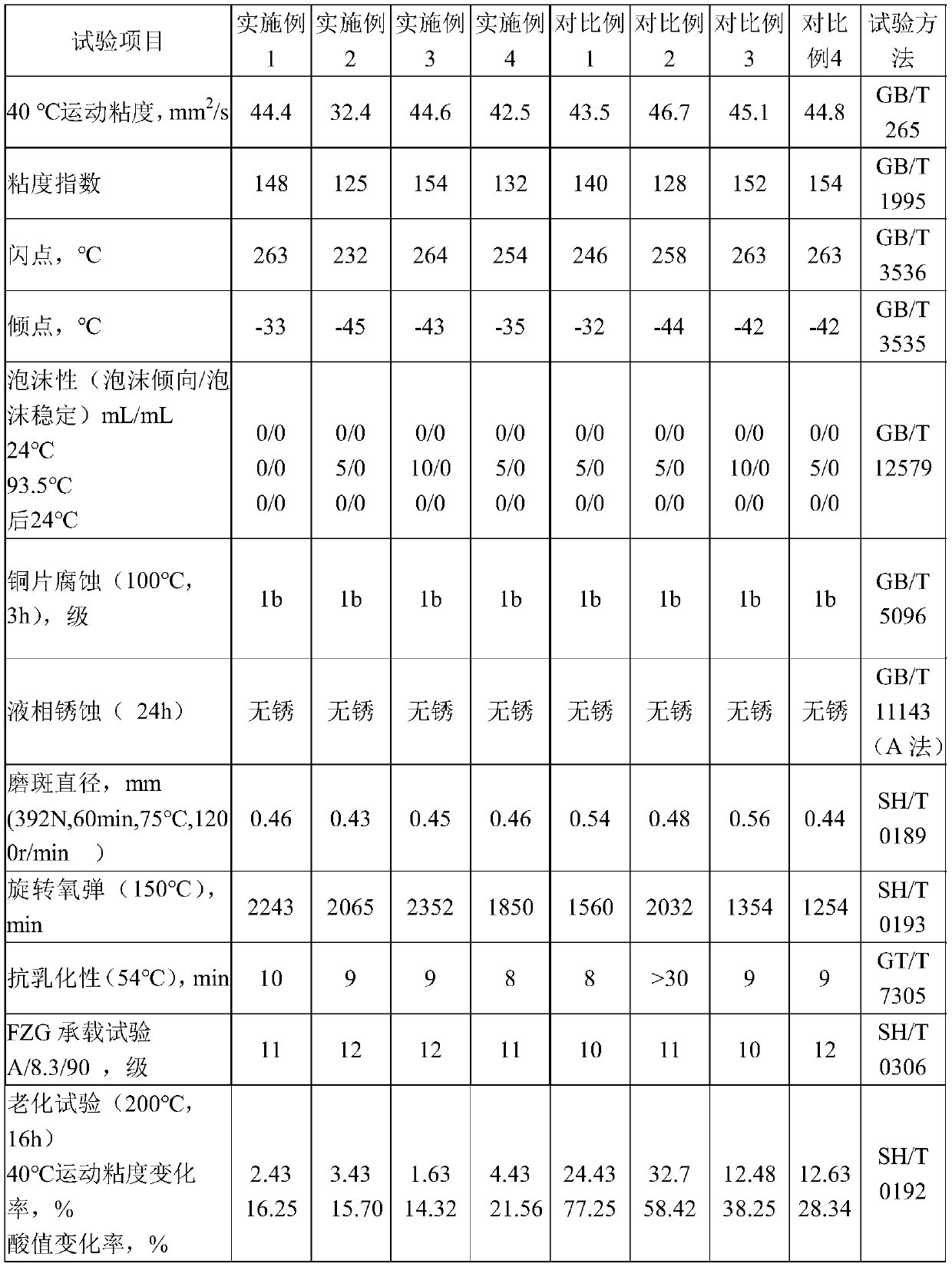

Examples

Embodiment 1

[0020] The long-life air compressor oil composition in the present embodiment is blended by the components of the weight percentage shown in the following table 1:

[0021] Table 1

[0022] components weight percentage III hydrogenated base oil GLT250 78.598% Oil-soluble polyether OSP-46 20% Additin RC9321 0.8% Additin RC6340 0.3% Antioxidant Additin RC7135 0.3% Antifoaming agent T901 0.002%

Embodiment 2

[0024] The long-life air compressor oil composition in the present embodiment is blended by the components of the weight percentage shown in the following table 2:

[0025] Table 2

[0026] components weight percentage III hydrogenated base oil 150N 82.698% Synesstic 5 15% HiTEC 543 1.2% Irgalube 353 0.1% Antioxidant Irgalube L57 1.0% Antifoaming agent T901 0.002%

Embodiment 3

[0028] The long-life air compressor oil composition in the present embodiment is blended by the components of the weight percentage shown in the following table 3:

[0029] table 3

[0030] components weight percentage III hydrogenated base oil GLT250 68.395% Oil-soluble polyether OSP-46 30% Irgalube 2030A 0.6% POPUC 4002 0.5% Antioxidant Irgalube L57 0.5% Antifoam agent VISCOPLEX 14-515 0.005%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com