Production process and device of high-purity methylal

A production process, methylal technology, applied in the field of high-purity methylal synthesis process and equipment, can solve the problems of affecting the quality of methylal products, increasing the difficulty of wastewater treatment, equipment investment and equipment occupying a large area, etc., to achieve The effect of product quality improvement, easy handling, and small investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

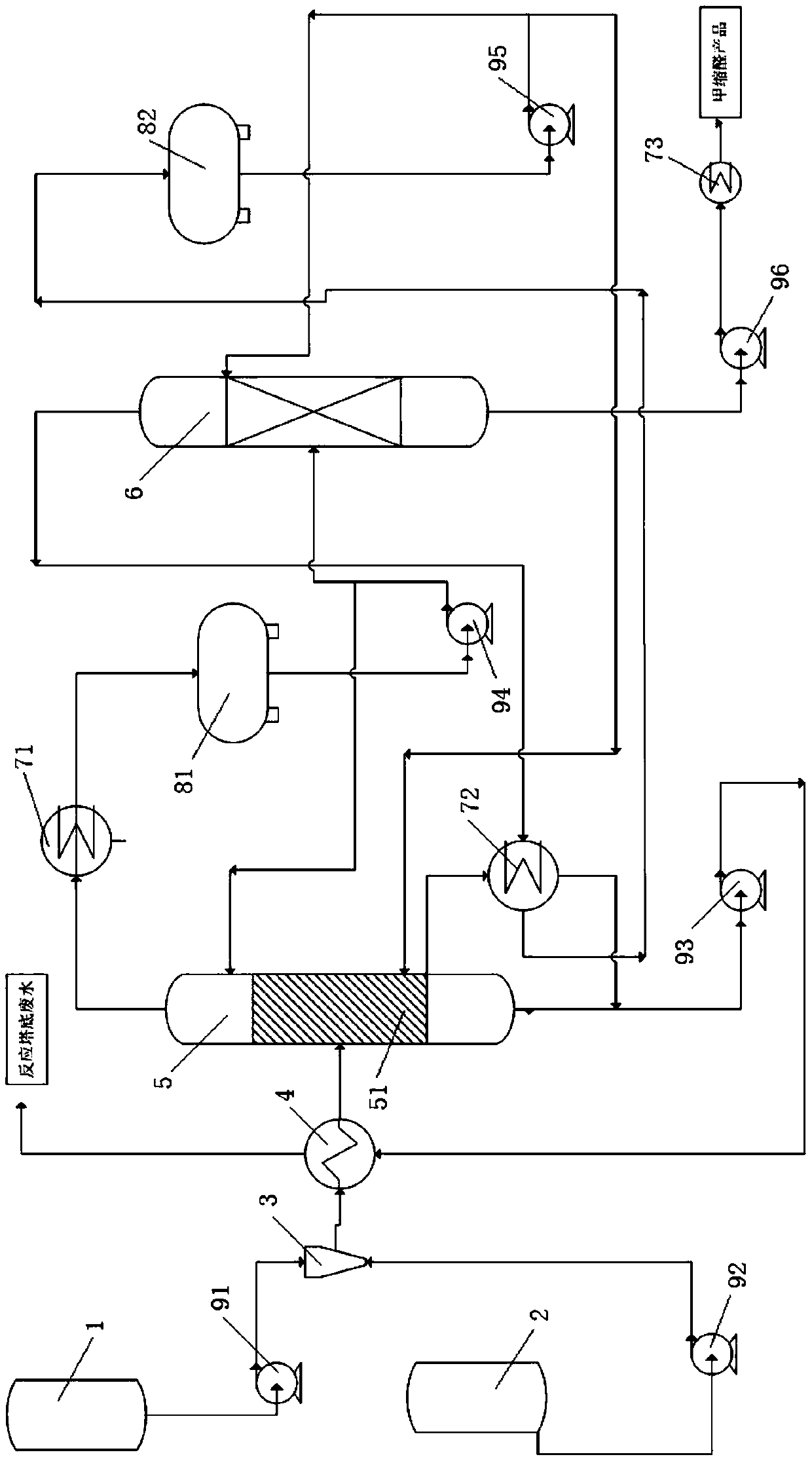

[0030] see figure 1 , a high-purity methylal production device, comprising a formaldehyde tank 1, a methanol tank 2, a raw material mixer 3 and a reactive distillation tower 5, a first pump 91 is set between the formaldehyde tank 1 and the raw material mixer 3, and the methanol tank 2 A second pump 92 is set between the raw material mixer 3, and a shell-and-tube heat exchanger 4 is set between the raw material mixer 3 and the reactive distillation tower 5, and the heat exchanger 4 is connected to the middle of the reactive distillation tower 5 , the lower part of the reactive distillation tower 5 is provided with a catalyst layer 51, and the top of the reactive distillation tower 5 is connected to the first condenser 71, the first reflux tank 81 and the pressurized rectification tower 6 in sequence, and also includes a second reflux tank 82, a fourth pump 94 is arranged between the first reflux tank 81 and the pressurized rectification tower 6, the fourth pump 94 is connected ...

Embodiment 2

[0038] (1) The methanol and formaldehyde solutions are respectively pumped into the raw material mixer 3 through the first pump 91 and the second pump 92 for mixing, then pass through the shell-and-tube heat exchanger 4, and then enter the reactive distillation tower 5 for reaction, wherein the raw material methanol The concentration is 99.5%, the formaldehyde concentration is 31.2%, the top temperature of the reactive distillation column is 36.5°C, the bottom temperature is 99.4°C, and the reflux ratio is 1.8 times the minimum reflux ratio. After the reaction, an azeotropic mixture of methylal and methanol is obtained. The composition of the azeotropic mixture is: 88.93% of methylal, 11.03% of methanol, and 0.04% of water; the composition of waste water at the bottom of the reactive distillation tower is: no methanol, 0.04% of formaldehyde; the catalyst layer 51 in the reactive distillation tower 5 It is a strongly acidic cation exchange resin, and the strong acidic cation exc...

Embodiment 3

[0041] (1) The methanol and formaldehyde solutions are respectively pumped into the raw material mixer 3 through the first pump 91 and the second pump 92 for mixing, then pass through the shell-and-tube heat exchanger 4, and then enter the reactive distillation tower 5 for reaction, wherein the raw material methanol The concentration is 99.5%, the formaldehyde concentration is 56.5%, the top temperature of the reactive distillation column is 43.5°C, the bottom temperature is 99.4°C, and the reflux ratio is 1.6 times the minimum reflux ratio. After the reaction, an azeotropic mixture of methylal and methanol is obtained. The composition of the azeotropic mixture is: methylal 91.82%, methanol 8.16%, water 0.02%; the waste water at the bottom of the reactive distillation tower is composed of: no methanol and 0.02% formaldehyde; the catalyst layer 51 in the reactive distillation tower 5 It is a strongly acidic cation exchange resin, and the strong acidic cation exchange resin is mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com