Nano TiO2 self-cleaning functional ceramic as well as preparation method and application thereof

A functional ceramic and self-cleaning technology, applied in the field of ceramic materials, can solve the problems of dirt formation, water droplets not easy to slip, and water marks formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034]In the present invention, the preparation method of the ceramic matrix preferably includes the following steps: drying, crushing, sieving, granulating and pressing in sequence after mixing the raw materials for preparing the ceramic matrix to obtain a dry compact; Sintering treatment to obtain a ceramic matrix; the sintering temperature is 1350-1420°C, and the sintering time is 60min-8h. In the present invention, the raw material for preparing the ceramic matrix is preferably soil satisfying the above material ratio. In the present invention, the moisture content of the material obtained after drying is preferably ≤3%; the mesh size of the sieve is preferably 150 mesh; and the pressing treatment is preferably performed by a 100T two-way dry press. In the present invention, the sintering temperature is preferably 1380-1420°C, more preferably 1400°C.

[0035] The present invention also provides nano-TiO described in the above-mentioned technical scheme 2 The preparatio...

Embodiment 1

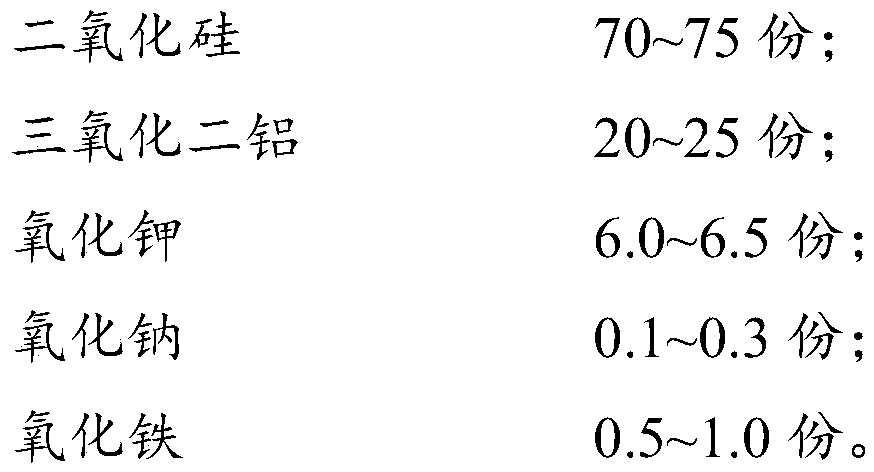

[0048] (1) Take 90kg of soil and dry it, with a moisture content of 3%, then crush it into fine particles and pass through a 150-mesh sieve for granulation, then put the particles into a mold, and press them with a 100T two-way dry press to obtain a dry billet ; Wherein the main chemical composition and its mass fraction in the dry billet are: Al 2 o 3 21%, SiO 2 72%, K 2 O 6.1%, Na 2 O 0.11%, Fe 2 o 3 0.7%, other trace components CaO, MgO;

[0049] Fire the dry compact at 1360°C for 7.5 hours to obtain a ceramic matrix;

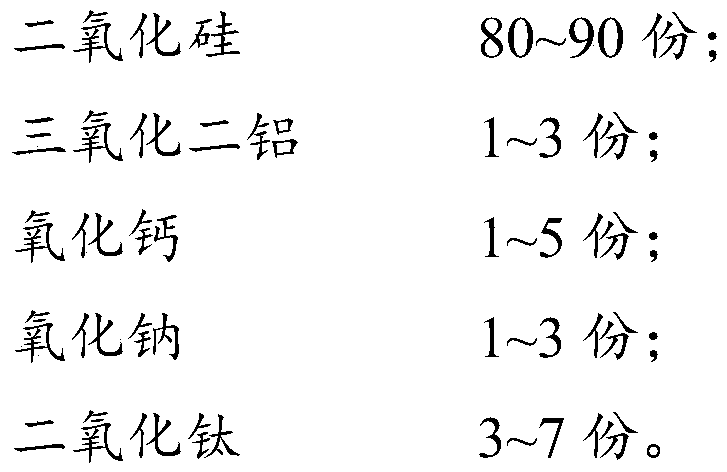

[0050] (2) Spray glaze water on the surface of the ceramic substrate, and then perform low-temperature firing at 1100 ° C for 6 hours to obtain nano-TiO 2 Self-cleaning functional ceramics; the main chemical composition and mass ratio of glaze water are SiO 2 :Al 2 o 3 :CaO:NaO:TiO 2 :H 2 O=85:2:1.5:1.5:3:7, wherein the particle size of silicon dioxide is ≤50μm; the particle size of aluminum oxide is ≤50μm; the particle size of titanium dioxide i...

Embodiment 2

[0052] Prepare ceramic substrate according to the method for embodiment 1;

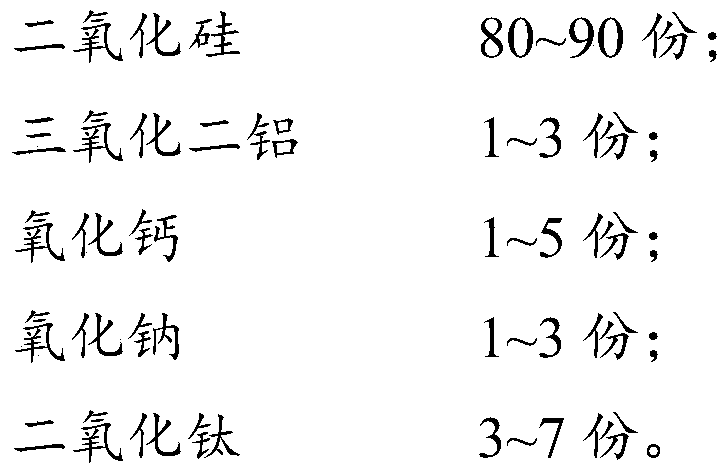

[0053] Spray glaze water on the surface of the ceramic substrate, and then fire at 1050 °C for 5 hours at a low temperature to obtain nano-TiO 2 Self-cleaning functional ceramics; the main chemical composition and mass ratio of glaze water are SiO 2 :Al 2 O: CaO: NaO: TiO 2 :H 2 O=84:3:1.5:1.5:3.5:6.5, wherein the particle size of silicon dioxide is ≤50μm; the particle size of aluminum oxide is ≤50μm; the particle size of titanium dioxide is 5~20μm, and the particle size of titanium dioxide is 5~ The volume percentage of 8 μm titanium dioxide is 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com