Method for preparing ammonium potassium polyphosphate from acid monopotassium phosphate

A technology of acid potassium dihydrogen phosphate and potassium dihydrogen phosphate, applied in the direction of ammonium orthophosphate fertilizer, chemical instruments and methods, alkaline orthophosphate fertilizer, etc., can solve the problem of low solubility, low nutrient concentration and harsh production conditions and other problems, to achieve the effect of simple preparation method, high nutrient concentration and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

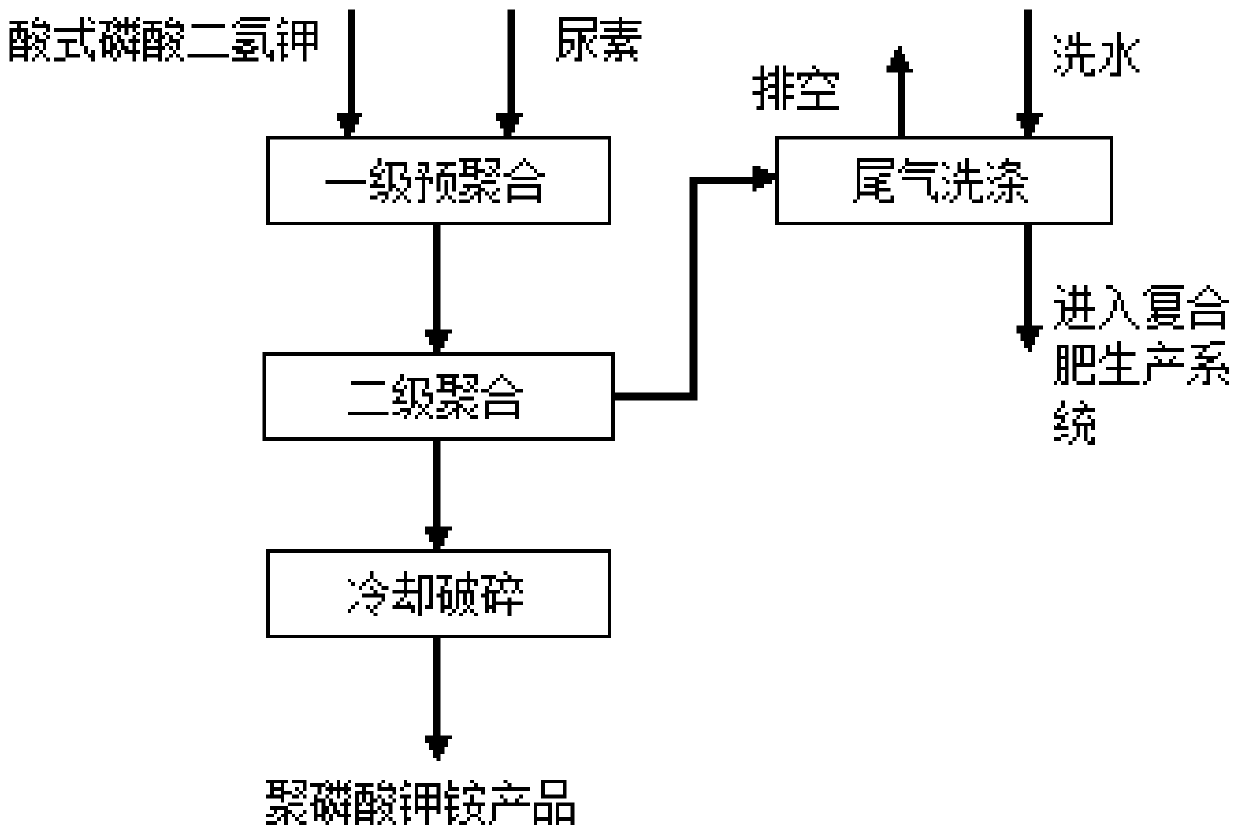

Method used

Image

Examples

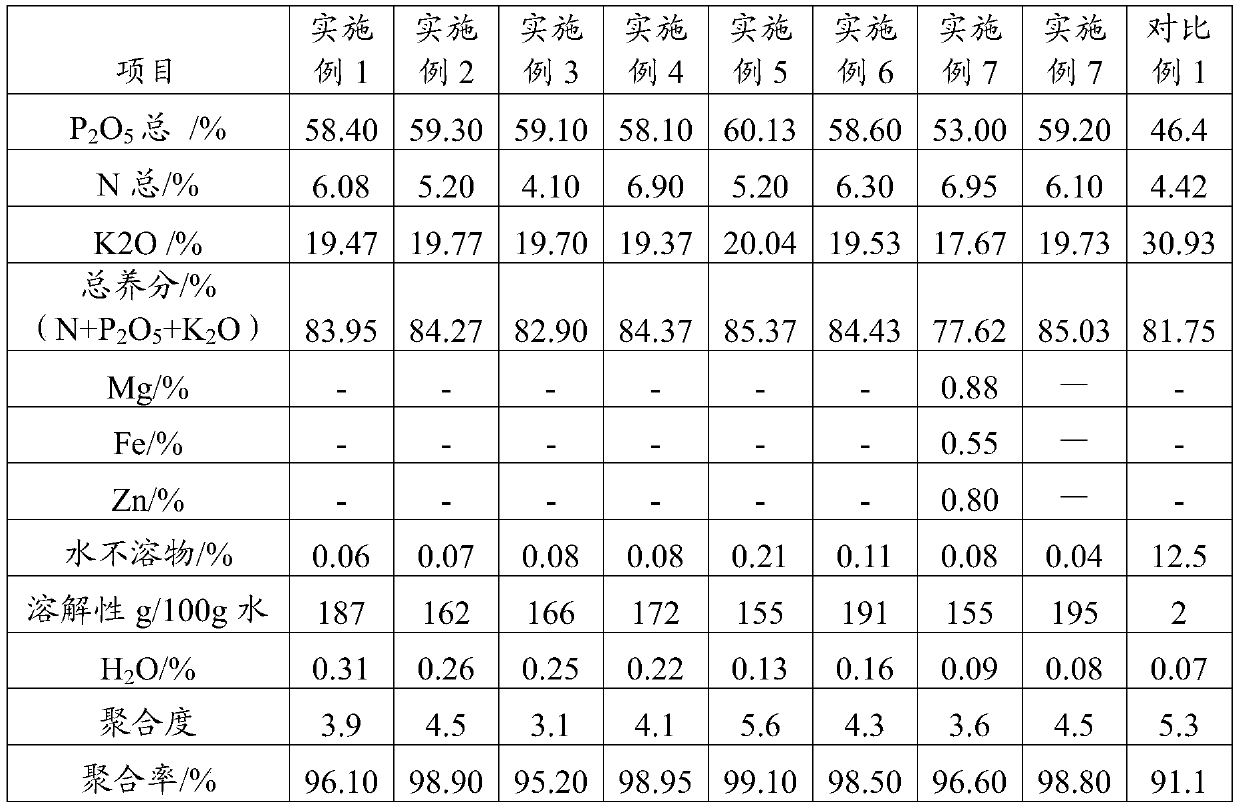

Embodiment 1

[0052] Get 1000g of acid potassium dihydrogen phosphate for reaction, add 150g of urea and mix evenly, pour the mixed material into the polymerizer, this polymerizer is a reaction tank with a jacket, and heat medium is passed into the jacket for indirect heating, Provide the heat required for polymerization. The polymerizer is also equipped with a high-speed stirrer to play the role of defoaming and mixing. The temperature inside the polymerizer is controlled at 140°C. As the material polymerizes and solidifies, the reaction continues for 2 hours. Take it out, cool it, and pulverize it. get the product. The product has good water solubility, the solubility in water at 25°C can reach 187g / 100g water, and the aqueous solution is completely clear after dissolution.

Embodiment 2

[0054] Take 1000 g of acid potassium dihydrogen phosphate for reaction, add 300 g of urea and mix evenly, pour the mixed slurry into the polymerizer, the polymerizer is the same as in Example 1, control the temperature in the polymerizer to 160 ° C, and the material is polymerized and solidified After that, continue to react for 2 hours, take it out, cool it, and pulverize it to get the product. The product has good water solubility, and the solubility in water at 25°C can reach 162g / 100g water, and the aqueous solution is completely clear after dissolution.

Embodiment 3

[0056] Take 1000 g of acid potassium dihydrogen phosphate for reaction, add 100 g of urea and mix evenly, pour the mixed slurry into the polymerizer, the polymerizer is the same as in Example 1, control the temperature in the polymerizer to 160 ° C, and the material is polymerized and solidified After that, continue to react for 2 hours, take it out, cool it, and pulverize it to get the product. The product has good water solubility, the solubility in water at 25°C can reach 166g / 100g water, and the aqueous solution is completely clear after dissolution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solubility in water | aaaaa | aaaaa |

| Solubility in water | aaaaa | aaaaa |

| Solubility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com