Degradable biodegradable film and preparation method thereof

A biodegradable film and biodegradable material technology, applied in the field of degradable biodegradable film and its preparation, can solve the problems of larger occupied area, film hemming, longer biodegradable film production line, etc., to achieve shortened production line, The effect of saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

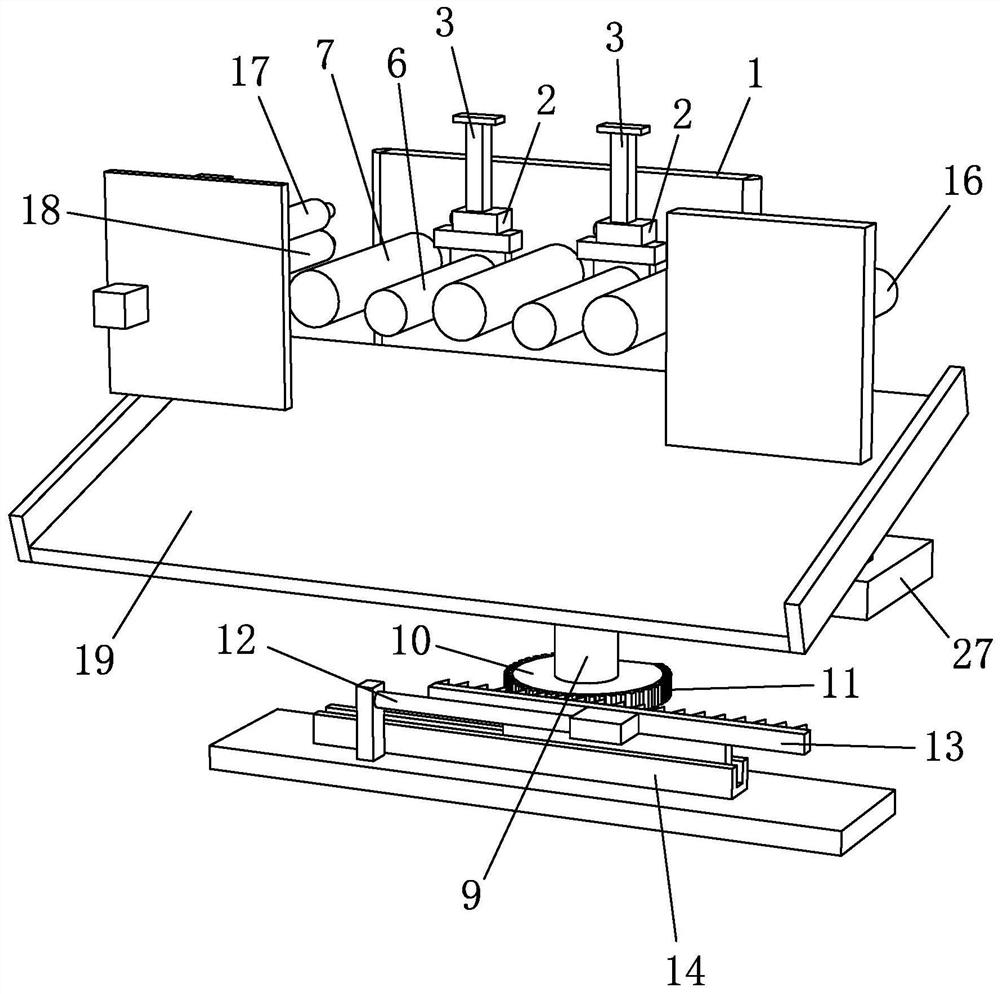

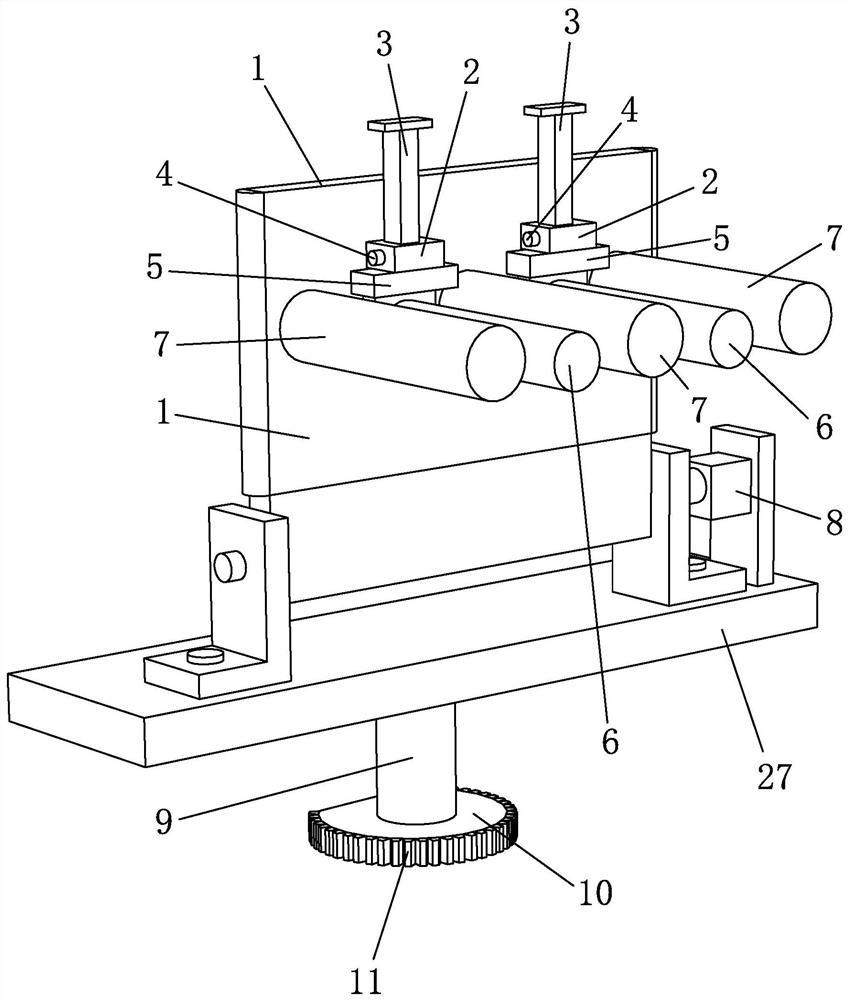

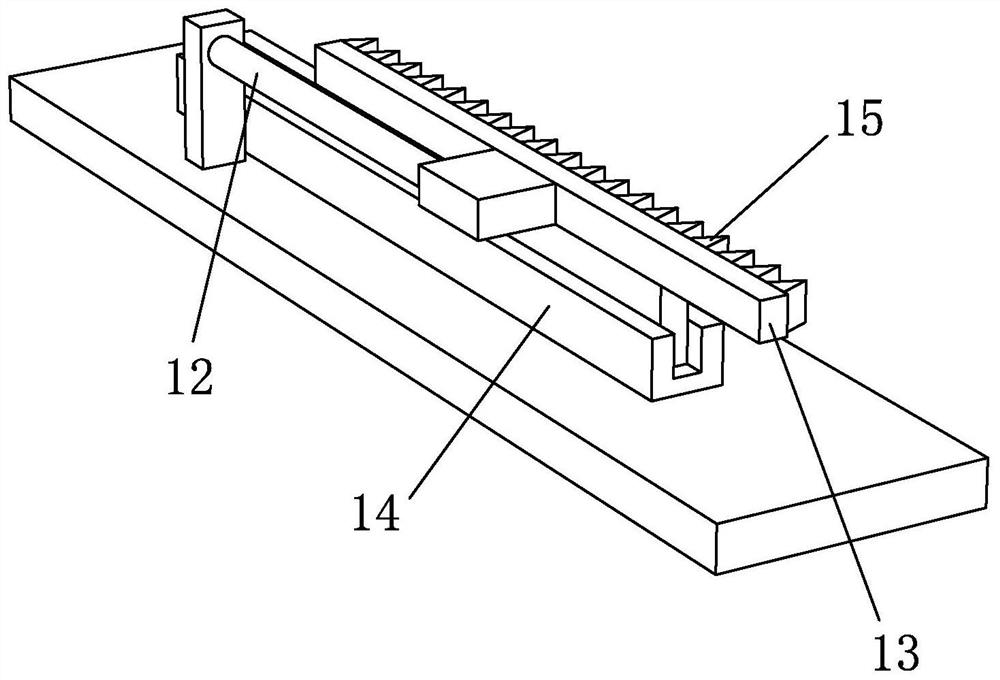

[0041] Such as Figure 1 to Figure 7 As shown, the degradable biodegradable film of the present invention includes an inner layer, a middle layer and an outer layer, and the middle layer is arranged between the inner layer and the outer layer,

[0042] The inner layer is composed of the following components by weight percentage: 20% to 100% of PBAT, 0% to 35% of PLA, 0% to 30% of starch, 0% to 30% of inorganic powder, and 0% to 50% of biodegradable materials , and modification additives 0% to 15%.

[0043] The middle layer is composed of the following components by weight percentage: 30% to 75% of PVA, 0% to 60% of PLA, 0% to 60% of PBAT, 0% to 30% of starch, 0% to 30% of inorganic powder, and biodegradable materials 0% to 50%, and modification additives 10% to 40%.

[0044] The outer layer is composed of the following components by weight percentage: 20% to 100% of PBAT, 0% to 35% of PLA, 0% to 30% of starch, 0% to 30% of inorganic powder, and 0% to 50% of biodegradable mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com