Ether electrolyte as well as preparation method and application thereof

A technology of electrolyte and ether, which is applied in the field of preparation of lithium-sulfur-like electrolyte, can solve the problems of low utilization rate of sulfur positive electrode, high specificity of electrolyte, and high solubility of polysulfides, and achieve polysulfide shuttling effect suppression, The effect of increasing utilization rate and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 1) Dry the LiTFSI powder and place it in an oven for 24 hours.

[0057] 2) Weigh 1.47g LiTFSI and 2.005g G2, mix them in a small sample bottle, and stir at room temperature for half an hour.

[0058] 3) Add 1.16mL HFE to the mixture and continue stirring for 20h. All the above operations were performed in a glove box.

[0059] 4) Assemble the battery with the sulfur-carbon composite positive electrode, the newly configured electrolyte solution (three drops), and the lithium sheet negative electrode, and compact them. Battery performance tests were performed at room temperature.

Embodiment 2

[0061] 1) Dry the LiFSI powder and place it in an oven for 24 hours.

[0062] 2) Weigh 1.31g LiFSI and 2.005g G2 and mix them in a small sample bottle, and stir at room temperature for half an hour.

[0063] 3) Add 1.16mL HFE to the mixture and continue stirring for 20h. All the above operations were performed in a glove box.

[0064] 4) Assemble the battery with the sulfur-carbon composite positive electrode, the newly configured electrolyte solution (three drops), and the lithium sheet negative electrode, and compact them. Battery performance tests were performed at room temperature.

Embodiment 3

[0065] Embodiment 3 performance test

[0066]The electrolyte solutions prepared in Example 1 and Example 2 were assembled into a battery, and the electrical performance test was carried out.

[0067] The preparation method of the positive electrode: mix the sulfur-carbon composite material, acetylene black, and PVDF at a mass ratio of 8:1:1 to obtain a slurry, and coat the slurry on the substrate with a thickness of 200-250 μm, and the substrate is carbon-coated aluminum foil to get the positive electrode. Battery assembly: add 3 drops (0.12mL) of the electrolyte on the positive electrode, the mass ratio of the positive electrode to the electrolyte is 0.12:0.2; then combine the negative lithium sheet with the positive electrode to obtain a test battery.

[0068] Charge and discharge performance test:

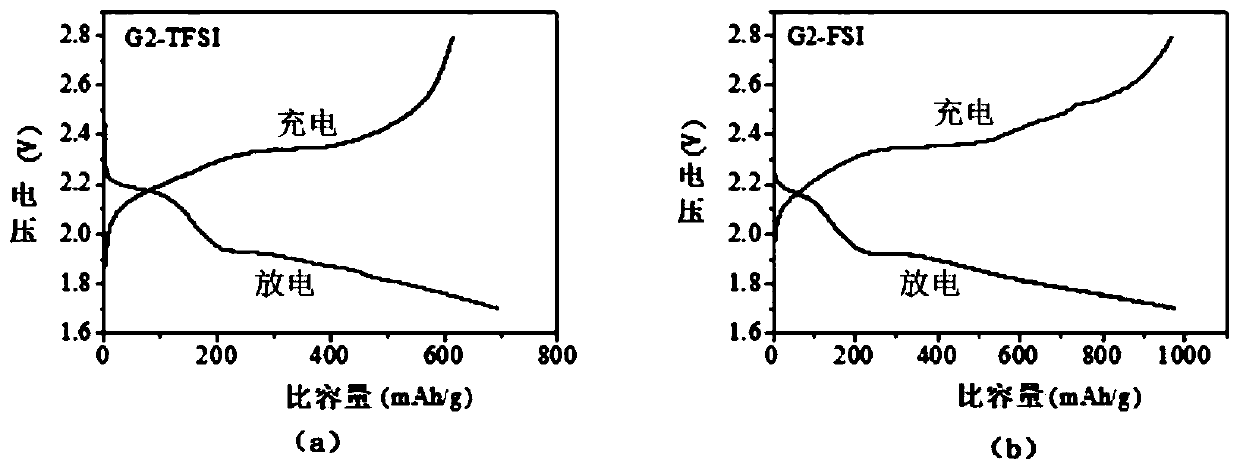

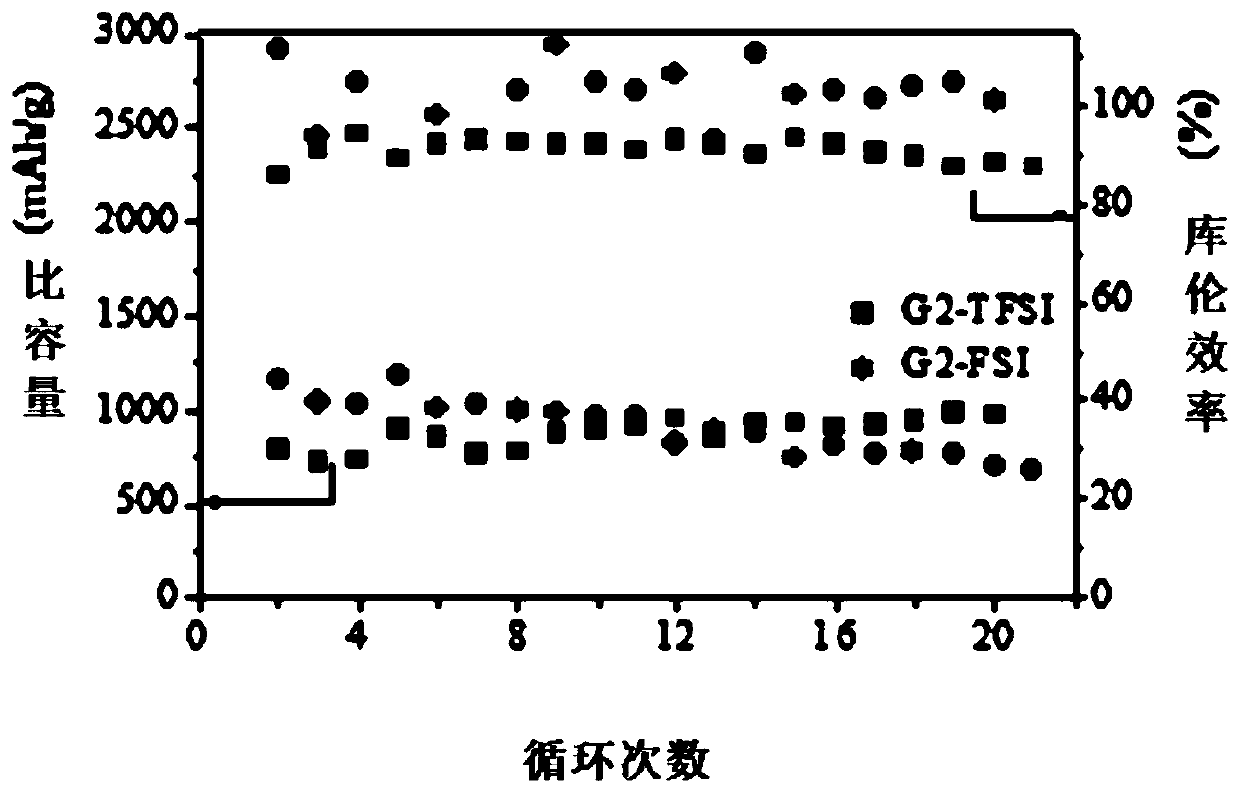

[0069] The test parameters are: constant current charge and discharge at a rate of 0.5C, and the voltage range is 1.7V to 2.8V. Test results such as figure 1 Shown, wherein ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com