Method for preparing carbon/nano manganese dioxide composite electrode material

A nano-manganese dioxide and composite electrode technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of complex preparation process, high synthesis temperature, and harsh conditions, and achieve simple equipment and preparation process, The effect of cheap raw materials and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

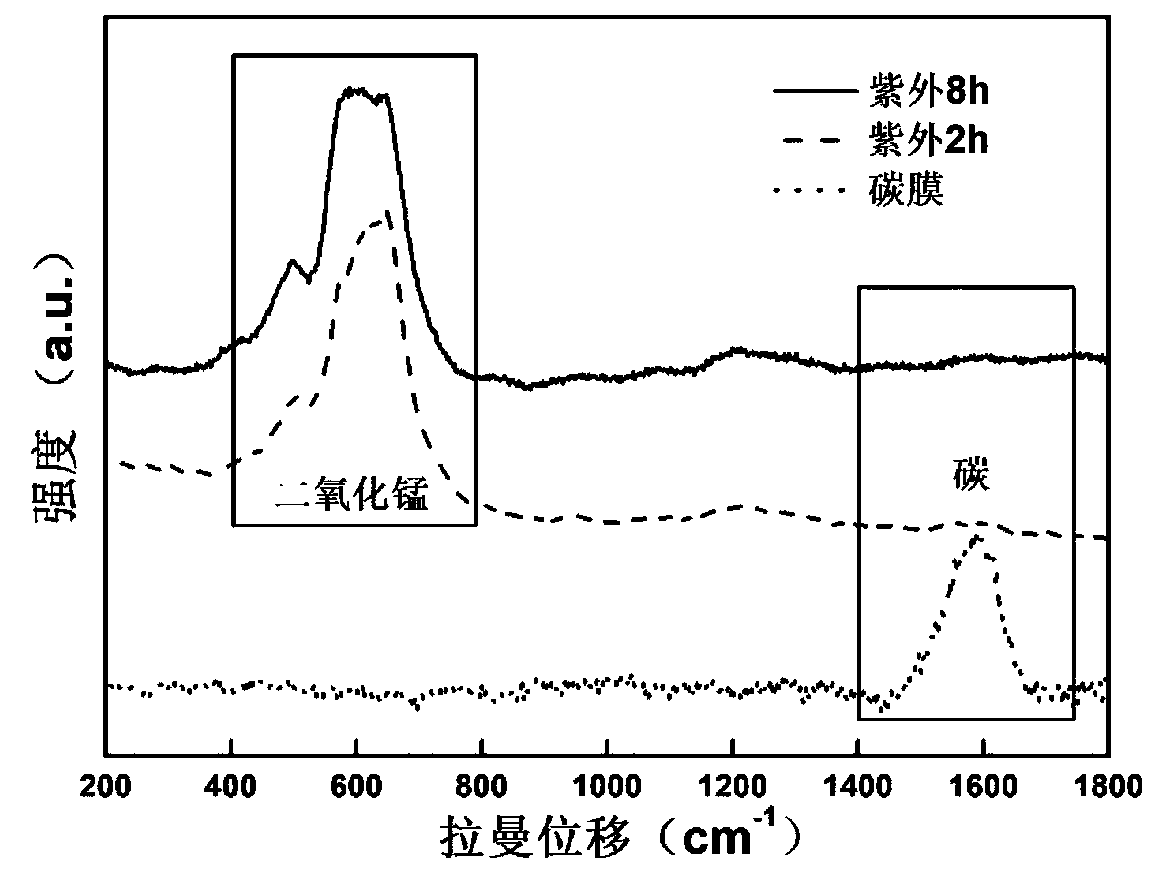

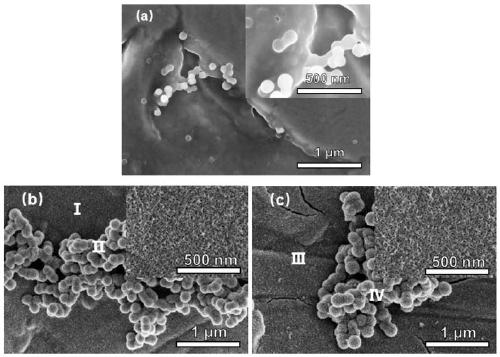

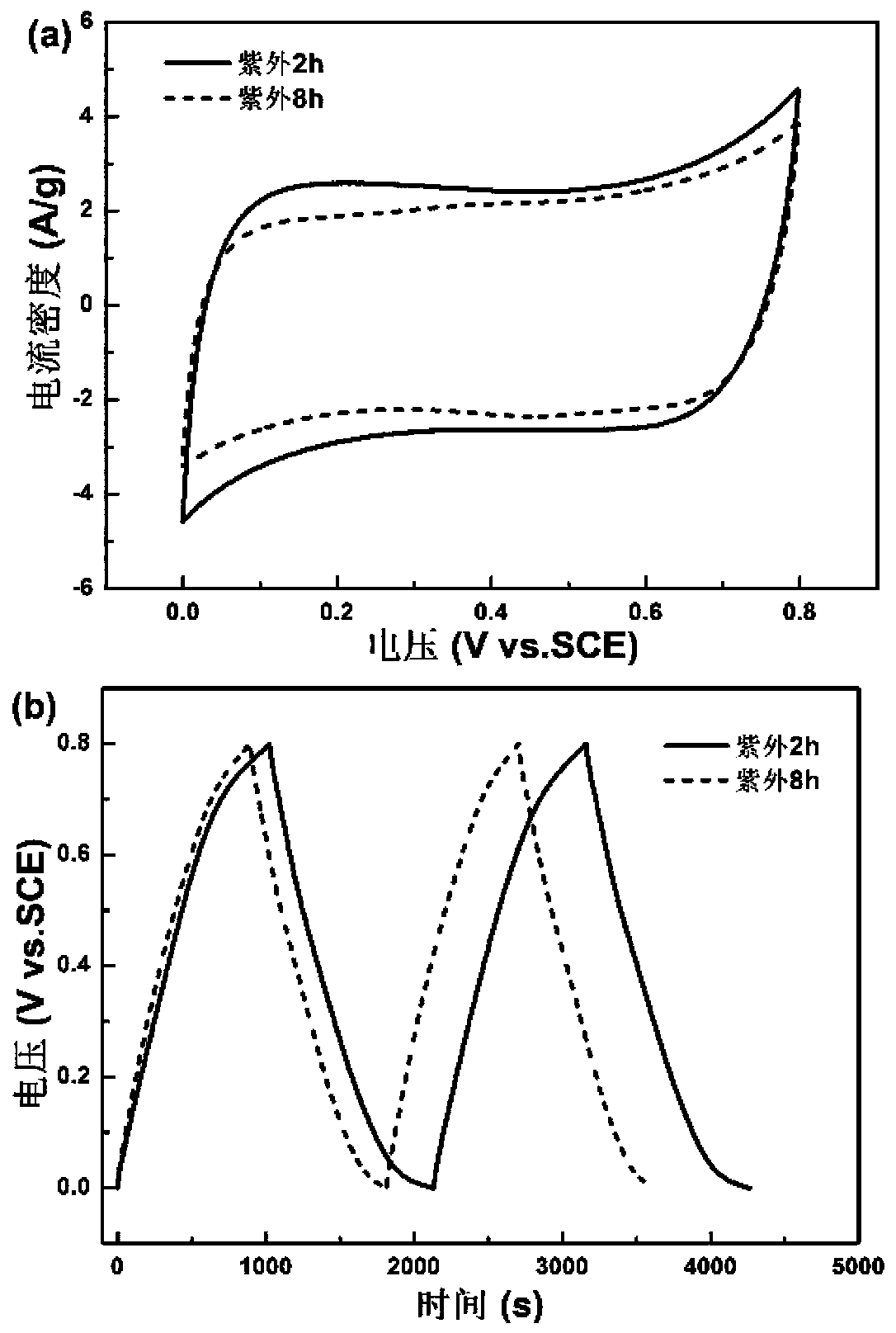

[0028] A: Preparation of carbon / manganese dioxide composite electrode materials by ultraviolet light reduction method

[0029] A carbon film was prepared on the surface of a titanium sheet electrode by hydrothermal carbonization reaction using glucose aqueous solution as precursor. Soak the carbon film-covered titanium sheet electrode material in an aqueous solution of potassium permanganate at a room temperature of about 25°C, and irradiate it with ultraviolet light for a period of time to grow nano-manganese dioxide on the surface of the carbon film. Wherein the volume of the above-mentioned aqueous glucose solution is 40 mL, and the mass fraction of glucose is 5%. The reaction temperature of the hydrothermal carbonization reaction method is 190° C., and the reaction time is 5 h. Potassium permanganate aqueous solution has a volume of 20 mL and a concentration of 0.01 mol / L. The power of the ultraviolet lamp is 48W, the distance between the lamp source and the liquid surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com