A detector using a wire array as a cathode, its use method and its calibration method

A detector and cathode technology, applied in the field of pulsed soft X-ray quantitative measurement, can solve problems such as difficulty in quantitative measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

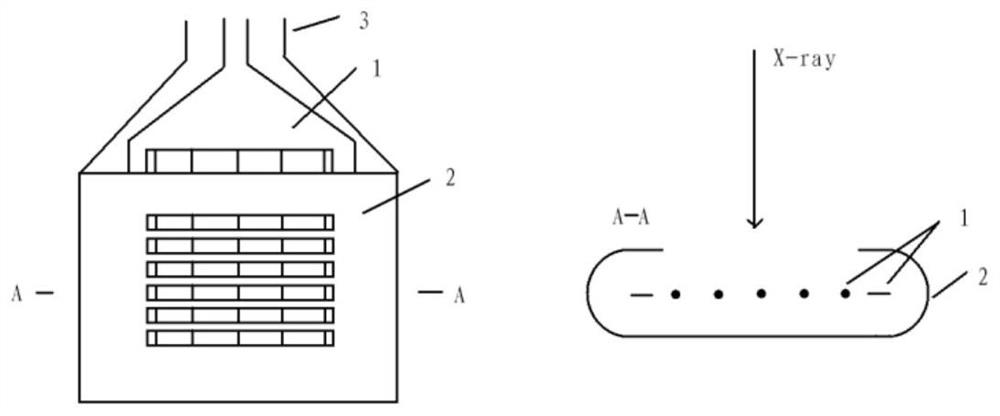

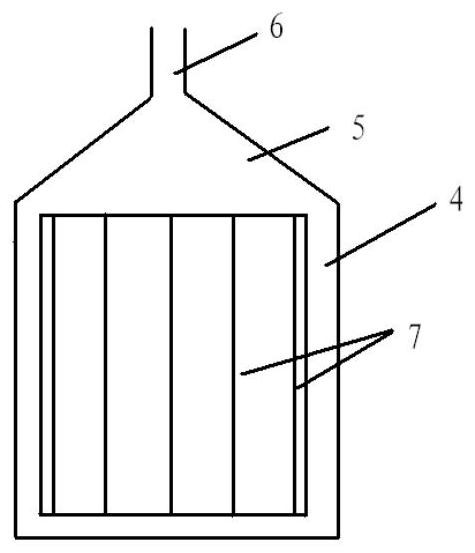

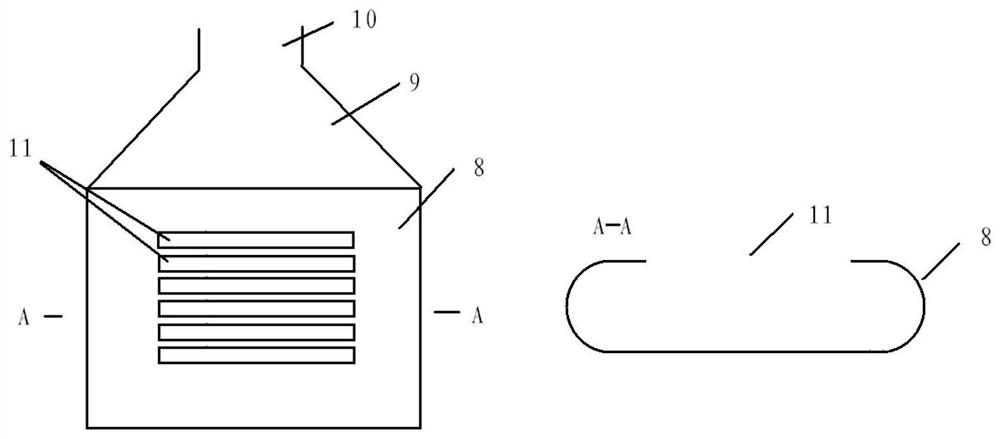

[0031] Please refer to Figure 1-Figure 3 The cathode wire array 7 is installed on the wire array frame 4 of the cathode assembly by hooking or welding, so that the cathode wire array 7 passes through the hole in the middle of the wire array frame 4 of the cathode assembly along a straight line. The cathode current drawing part 5 is connected with the wire array frame 4 of the cathode assembly. A light-transmitting hole 11 is opened on the wraparound anode sheet 8 , and the wraparound anode sheet 8 is connected with the anode current drawing part 9 . The cathode assembly 1 is placed inside the anode assembly 2, so that the central axis of the cathode assembly 1 coincides with the central axis of the anode assembly 2, and the minimum distances between each part of the cathode assembly 1 and the anode assembly 2 are approximately equal. Adjust the positional relationship between the cathode wire array 7 and the light-transmitting holes 11 on the surrounding anode sheet, so that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com