Method for continuously producing low-alcohol sweet wine and grape skin-residue fruit juice wine

A technology of sweet wine and grape pomace, which is applied in the field of wine making, can solve the problems of unsatisfactory and waste, and achieve the effect of simple operation, high utilization rate of raw materials and strong taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

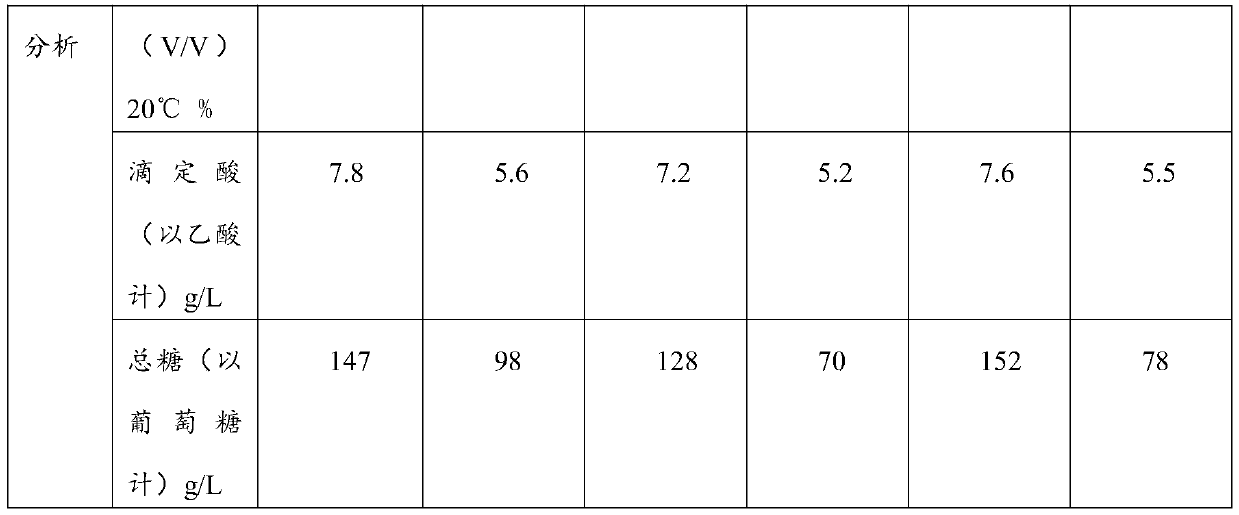

Embodiment 1

[0040] a. Select 3 tons of Merlot grapes, 1 tons of Muscat grapes, 3 tons of Muscat grapes, 3 tons of Muscat grapes, and 1 ton of Muscat grapes that are fully mature and of good quality, sort, destem, grain sort, and crush to obtain grape must, and control the destemming rate to greater than 90% %, the broken rate is greater than 70%. Add sulfur dioxide and 25mg / L pectinase to the grape must, detect the free sulfur dioxide content in the grape must, keep it at 30mg / L, circulate evenly, soak at 3-10°C for 3 days at low temperature, 230g of grape must reducing sugar / L.

[0041] b. Obtain grape juice A and solid part after maceration, extract all grape juice A and store in a 3-10°C freezing tank, squeeze the solid part, and obtain grape juice B and solid residue after pressing.

[0042] In this embodiment, 3.6t of grape juice A, 2.0t of grape juice B and 2.0t of solid residue were obtained.

[0043] c. Pump grape juice B into the fermentation tank, add yeast at a concentration...

Embodiment 2

[0049] a. Select 5t of fully mature Merlot grapes, 1t of Muscat grapes and 2t of Gernischt grapes, destem, grain sort, and crush to obtain grape mash, control the destemming rate to greater than 90%, and the crushing rate to greater than 70%. Add sulfur dioxide and 25mg / L pectinase to the grape must, detect the free sulfur dioxide content in the grape must, keep it at 30mg / L, circulate evenly, soak at 3-10℃ for 3 days, the sugar content of the grape must 200g / L.

[0050] b. Obtain grape juice A and solid part after maceration, extract all grape juice A and store in a 3-10°C freezing tank, squeeze the solid part, and obtain grape juice B and solid residue after pressing.

[0051] This embodiment obtains 3.2t of grape juice, 1.8t of grape juice B, and 2.6t of solid residue.

[0052] c. Pump grape juice B into the fermentation tank, add yeast at a concentration of 20mg / L, control the fermentation temperature at 18-20°C, periodically circulate ventilation and oxygen supply, and m...

Embodiment 3

[0058] a. Select 7 tons of fully mature Merlot grapes and 1 tg of Muscat grapes, destem, grain sort, and crush to obtain grape must, control the destemming rate to greater than 90%, and the crushing rate to greater than 70%. Add sulfur dioxide and 25mg / L pectinase to the grape must, detect the free sulfur dioxide content in the grape must, keep it at 50mg / L, circulate evenly, soak at 3-10°C for 3 days, the sugar content of the grape must 220g / L.

[0059] b. Obtain grape juice A and solid part after maceration, extract all grape juice A and store in a 3-10°C freezing tank, squeeze the solid part, and obtain grape juice B and solid residue after pressing.

[0060] In this embodiment, 3.6t of grape juice A, 1.6t of grape juice B and 2.4t of solid residue were obtained.

[0061] c. Pump grape juice B into the fermentation tank, add yeast at a concentration of 20mg / L, control the fermentation temperature at 18-20°C, periodically circulate ventilation and oxygen supply, and measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com