A secondary shaping device for fiberboard composite board

A composite board and fiberboard technology, which is applied in the direction of cleaning methods using liquids, other household appliances, chemical instruments and methods, etc., can solve the problems of easy slippage, large wear and tear of glass fiber reinforced plastic gratings, and high purchase costs, so as to reduce waste of resources. , Increase the service life, the effect of high purchase cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

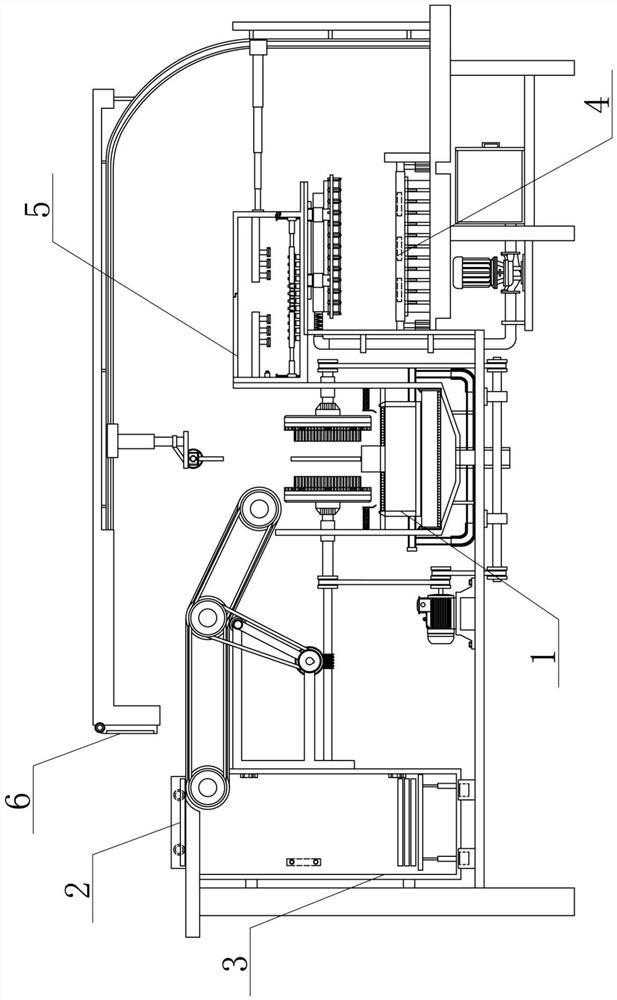

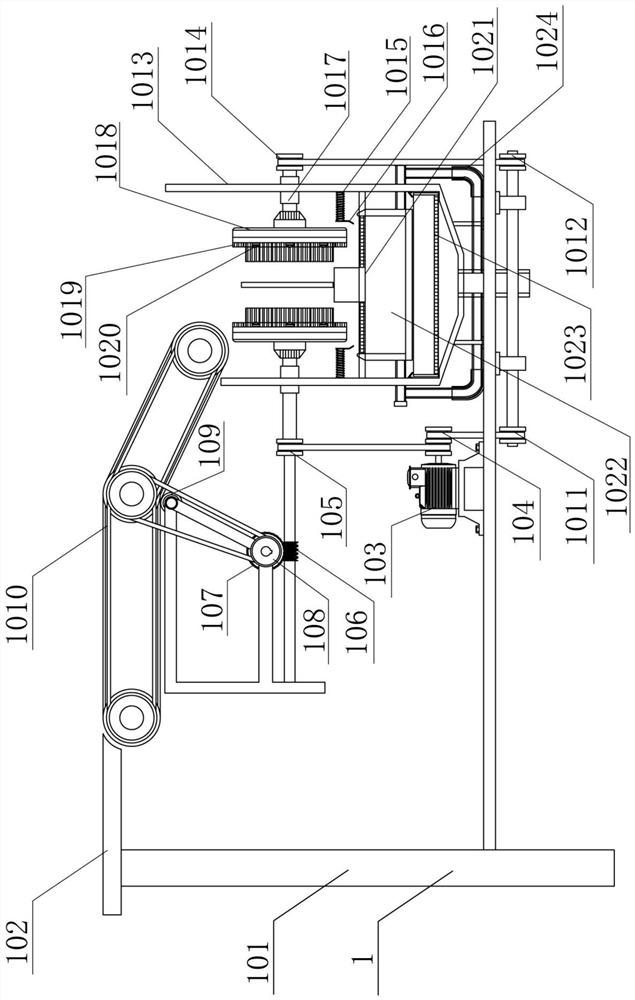

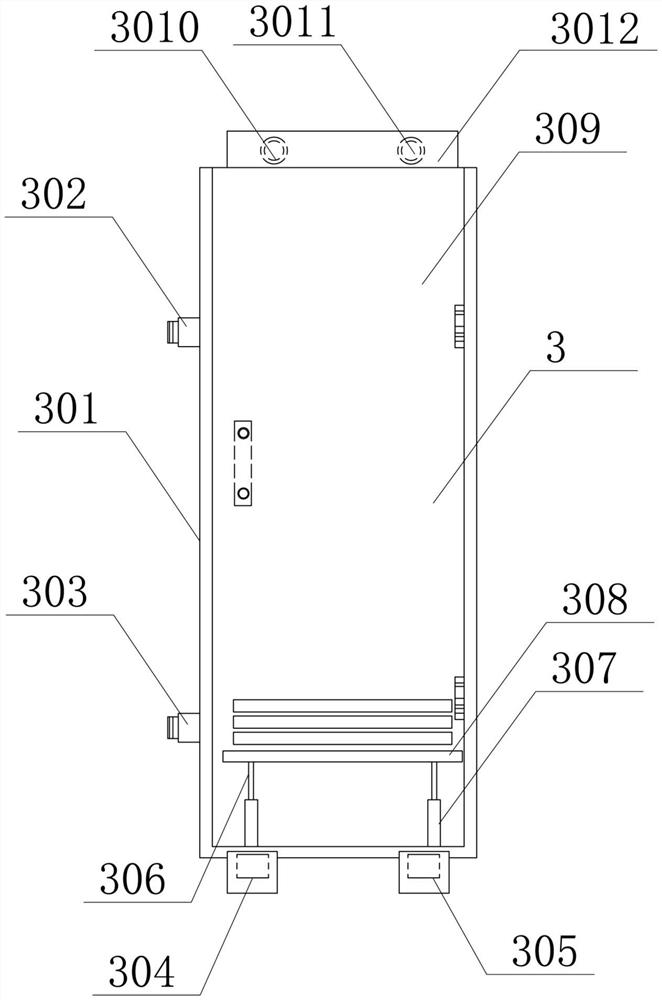

[0028] A secondary shaping device for fiberboard composite boards, including an orientation processing mechanism 1, a FRP grid plate 2, a positioning and feeding mechanism 3, a shaping mechanism 4, a shaping mechanism 5, and a control panel 6; the top of the orientation processing mechanism 1 is placed on the left side There are FRP grating plates 2; the left side of the orientation processing mechanism 1 is provided with a positioning feeding mechanism 3; the right side of the orientation processing mechanism 1 is provided with a shaping mechanism 4; the top of the right end of the orientation processing mechanism 1 is provided with a shaping mechanism 5, and 5. The bottom and the right end are all connected with the shaping mechanism 4; the left top of the shaping mechanism 4 is turned over and connected with the control panel 6.

[0029] Working principle: When using, place the secondary shaping device of fiberboard composite board in the position to be used, then connect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com