Directional Solidification Device and Process Method for Improving Single Crystal Blade Deposit

A technology for directional solidification and single crystal blades, which is applied in the field of directional solidification devices for improving deposits of single crystal blades, directional solidification devices, and the production of single crystal blades. To achieve the effect of improving nucleation and competitive growth conditions, improving the quality of crystal selection, and reducing the deposition of trace components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

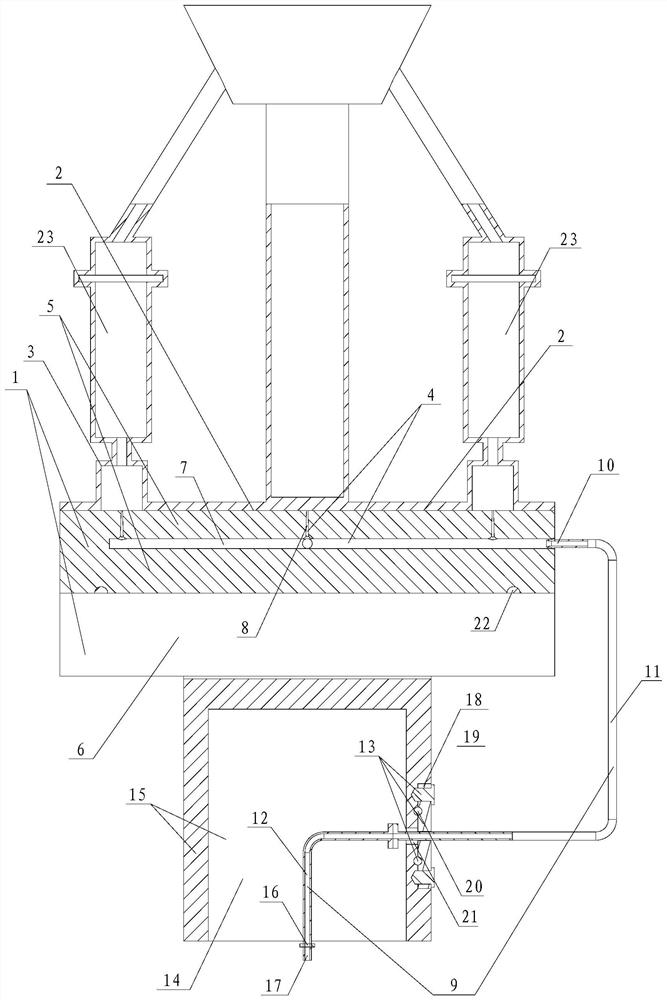

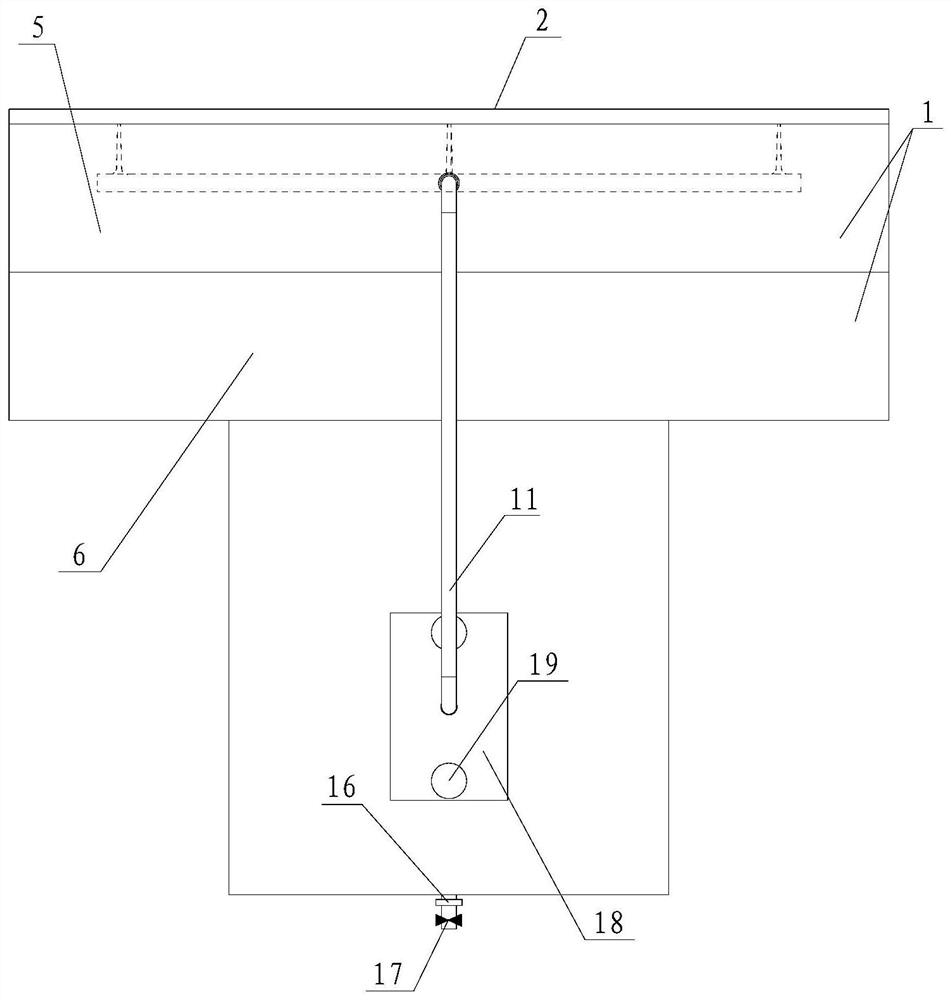

[0034] The description will be further described below in conjunction with the accompanying drawings.

[0035] The directional solidification process of single crystal blades includes the fixing, heating, and heat preservation of the formwork; the melting and casting of alloys, the drawing and cooling of blades, and other processes; Atmosphere, the volatilization of trace elements in the mold shell will be deposited in places with lower temperatures such as the water cooling plate, the bottom plate of the mold shell, and the crystal selector, which will affect the nucleation and growth of grains, resulting in defects such as miscellaneous crystals and inclusions that cause blade scrapped.

[0036] Such as figure 1 , figure 2 The shown directional solidification device for improving single crystal blade deposits includes a formwork, a water cooling plate and a drawing shaft; the formwork is fixed on the water cooling plate, and the water cooling plate is installed directly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com