A kind of preparation method of catalyst and its application

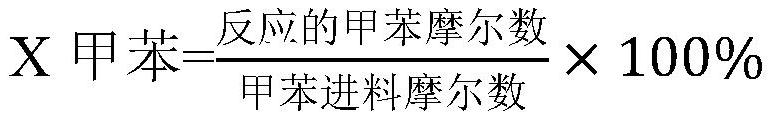

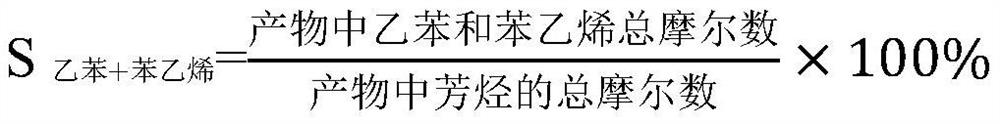

A catalyst, cesium hydroxide technology, applied in the field of catalysis, can solve the problem of low conversion rate of toluene, achieve high conversion rate of toluene, high total selectivity, and facilitate large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Example 1: Preparation of alkaline molecular sieve samples

[0074] The Nax molecular sieve of 75 g of silicon aluminum ratio (Si / Al) was taken from 0.2, 0.4 and 0.6 mol / L of CSOH solution, 3 times at 80 ° C, respectively, with deionized wash. Several times, then centrifuged, dried overnight at 100 ° C, and baked at 540 ° C for 3 h. Sample obtained with different concentrations of exchanges is A-1 # A-2 # A-3 # .

[0075] The sample number, ion exchange liquid type and concentration and ion exchange were as shown in Table 1. Element analysis of the resulting sample was analyzed by XRF element analysis, and the ion exchange was calculated based on the cation equivalent of the zeolite phase in exchange.

[0076] Table 1 Preparation conditions for alkaline molecular sieve samples

[0077]

Embodiment 2

[0078] Example 2: Preparation of Catalyst Samples

[0079] The basic molecular sieve sample A-1 obtained by preparing in Example 1 # ~ A-3 # At least one ball milling for 30 min, 60min, 90min, 120min and 150min, the obtained catalyst was recorded as CAT-1 # ~ CAT-15 # . The rotational speed of the ball mill is 550 rpm, the weight ratio of the ball and molecular sieve in the ball mill is 9: 1, and the weight ratio of deionized water to the molecular sieve is 3: 1. Samples after ball milling were dried at 100 ° C for 8 hours; then bake at 540 ° C for 3 hours.

[0080] The number of the obtained catalyst sample and the ball milling time are shown in Table 2.

[0081] Table 2

[0082]

[0083] Contraction: 1 Preparation of Catalyst Samples

[0084] The Nax molecular sieve of 25 g of silicon aluminum aluminum ratio (Si / Al) was taken, and five parts were divided into five parts by mass, and each part was grinded for 30 min, 90min, 120min and 150min. The rotational speed of the ball ...

Embodiment 3

[0088] Example 3: Evaluation of catalyst

[0089] Table 1, Table 2, and Table 3, the catalyst tables were broken and sieved to be 40-60 mesh, each of which was taken into a small fixed bed reactor, and the catalyst was filled with stone sand, the catalyst first was first in 10 ml. The / MIN flow rate is activated by 500 ° C for 1 h, then drown to the reaction temperature, pumps with high pressure constant current pumps into raw material toluene methanol, glycerol ratio, vacancy, reaction pressure, and reaction temperature, see Table 4. The product was detected by Agilent 7890B gas chromatograph, and the reaction results are shown in Table 4. Table 4 shows that the catalyst of the prior ion exchange rear ball milling is increased by the catalyst of the prior ion exchange, and the total selectivity of the toluene is increased, especially the toluene conversion is greatly improved. Ball mill increases, toluene conversion and total selectivity of ethylfinhenyrene is reduced. The ion e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com