Pressurizing hemostatic patch for transfusion

A technology of hemostatic patch and pressure plate, which is applied in the field of medical devices, can solve the problems of restricted movement of patients and medical staff, bleeding from infusion needle holes, and short pressing time, so as to improve the healing speed, prevent bleeding, and reduce bruises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

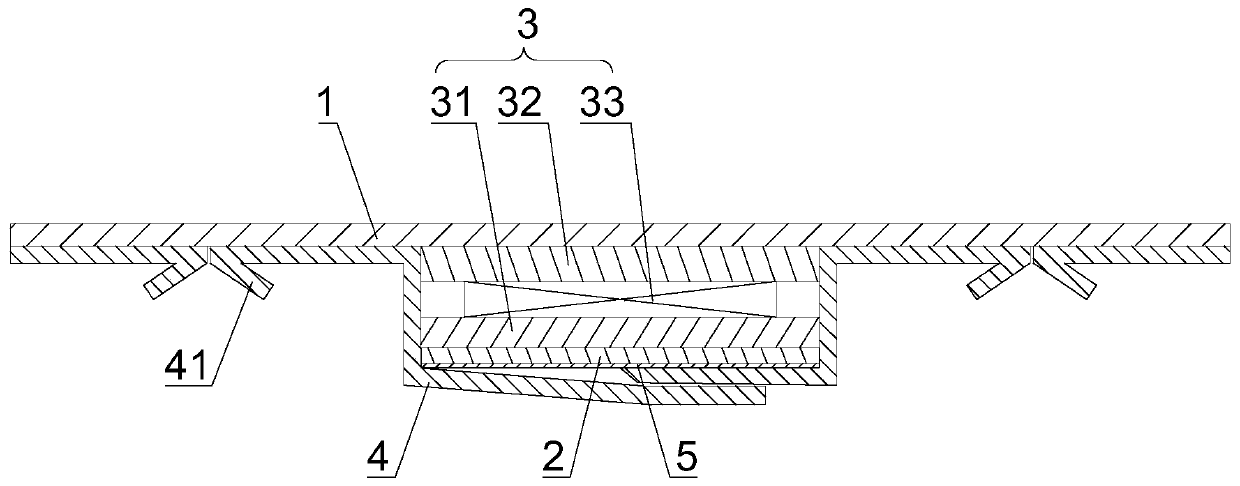

[0027] See figure 1 As shown, this embodiment provides an infusion pressurized hemostatic patch, which mainly includes a medical tape 1, a sterile anti-inflammatory block 2 and a pressurizing device 3.

[0028] The pressure device 3 includes a pressure plate 31, a pressure release plate 32, and a reset member 33. The pressure plate 31 and the pressure release plate 32 are locked to be relatively stationary by a lock structure. The reset member 33 is sandwiched between the pressure plate 31 and the pressure release plate 32. At this time, the pressurizing device 3 is in an energy storage state, and all components are made of medical materials.

[0029] The sterilization and anti-inflammatory block 2 is arranged on the outside of the pressure plate 31 and abuts against the bleeding port of the part to be hemostatic. The sterilizing and anti-inflammatory block 2 is made of medically flexible and sterile materials, which can be one or more of sterilized expanded sponge, re-foamed spong...

Embodiment 2

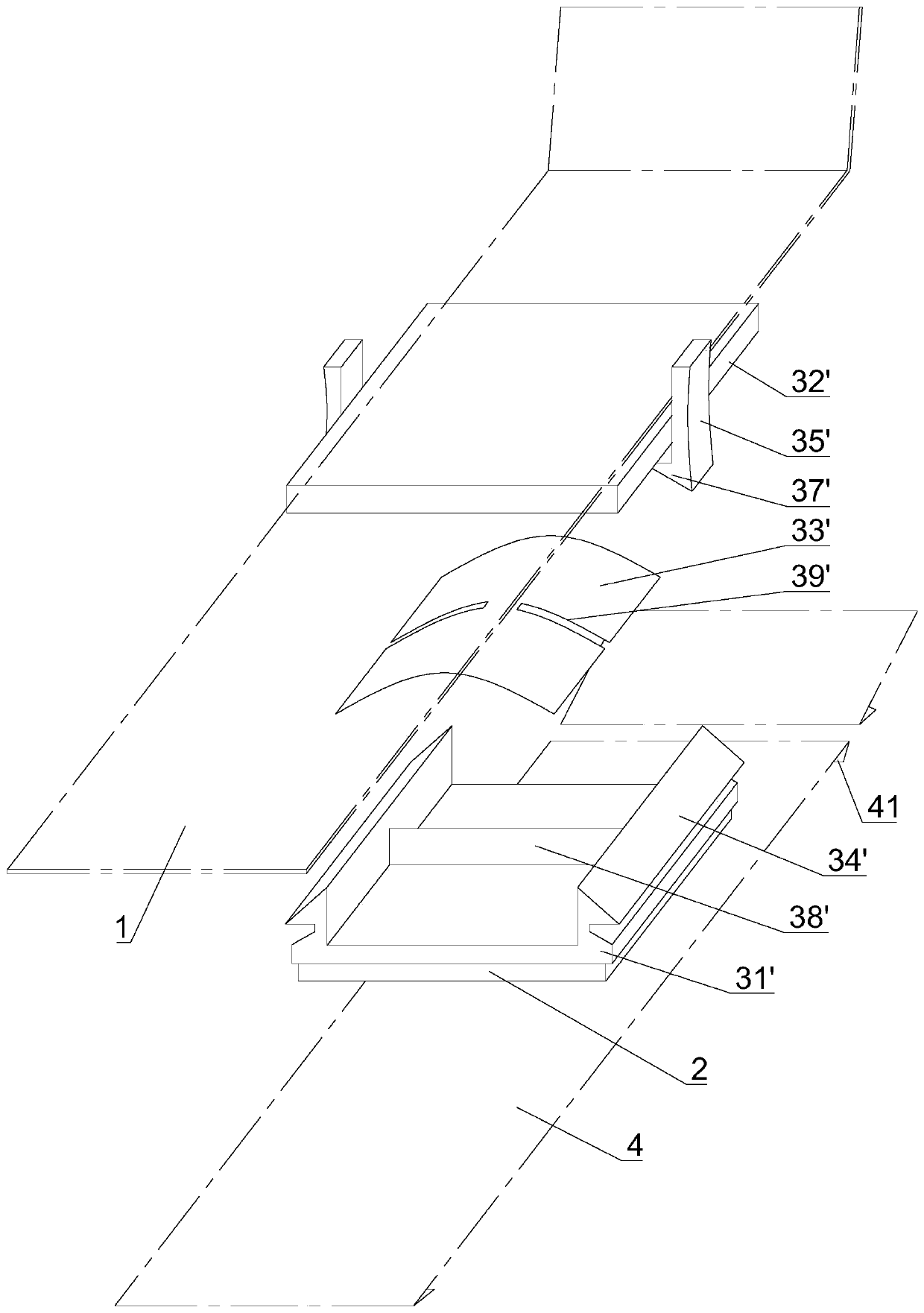

[0036] See figure 2 with 3 As shown, this embodiment provides an infusion pressurizing hemostatic patch, and the pressurizing device is further designed on the basis of Embodiment 1.

[0037] In the pressing device 3', the two sides of the pressing plate 31' protrude to form a clamping wall, the clamping wall is provided with a first hook 34', and both sides of the pressure release plate 32' are provided with decompression handles 35 ', the end of the decompression handle 35' beyond the upper surface of the release plate 32' is the pressing portion 36', and the end beyond the lower surface of the release plate 32' forms a second hook 37'. The first hook 34' and the second The hook portion 37' cooperates with the buckle to form a lock structure. After pressing the pressing portions 36' on both sides, the decompression handle 35' is elastically inclined, and the first hook portion 34' and the second hook portion 37' are separated and unlocked.

[0038] The restoring member 33' can b...

Embodiment 3

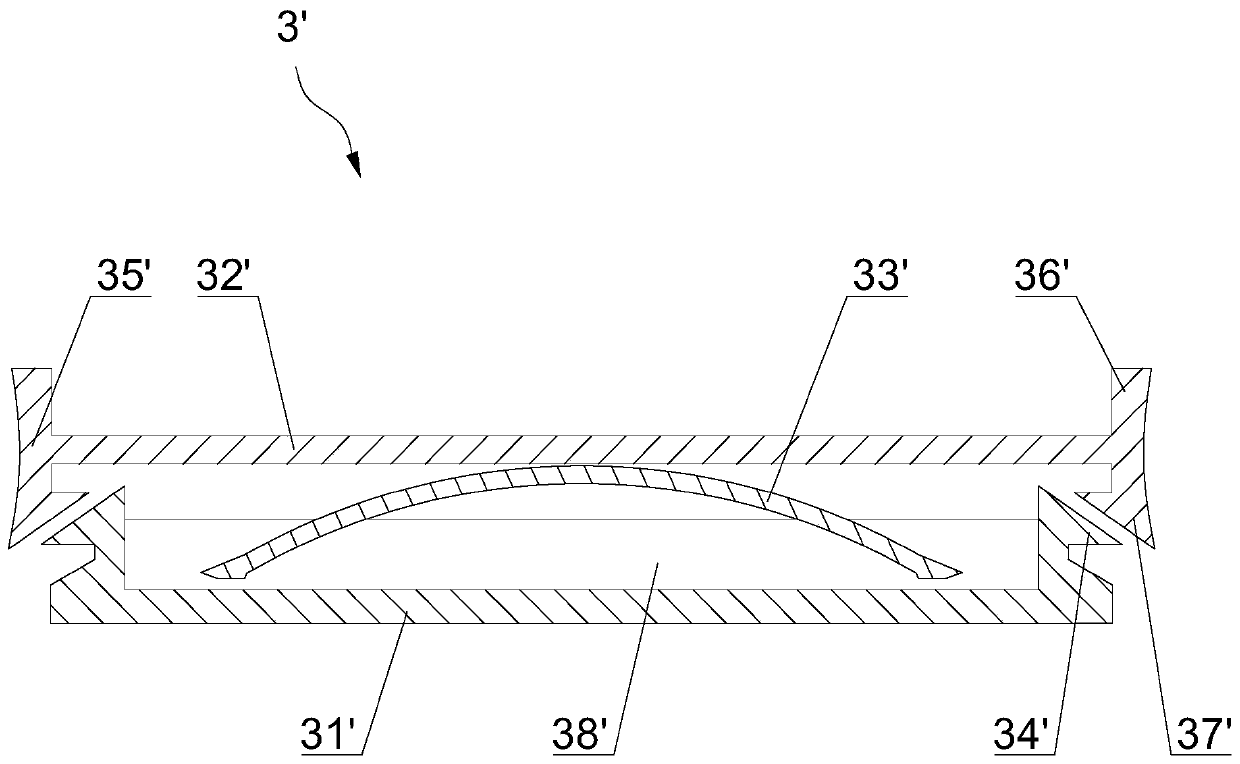

[0042] See Figure 4 with 5 As shown, this embodiment provides an infusion pressurizing hemostatic patch, and the pressurizing device is further designed on the basis of the second embodiment.

[0043] The difference from Embodiment 2 is that the resetting piece 33' here is an arched shrapnel, the dome of the arched shrapnel is fixedly connected to the pressure plate 31', and the arch edge is in contact with the pressure plate 31' and the edge is arched when stressed Deformed outwards, and the release plate 32', the decompression handle 35', and the reset piece 33' are integrally formed with medical materials, so that the setting of the limit card 38' and the limit slot 39' can be omitted, and the press pressure. The rest of the structure is the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com