Heat insulation PVC wallboard and production process thereof

A technology for thermal insulation and wallboard, applied in the field of wallboard, can solve the problems of poor thermal insulation of PVC wallboard, unfavorable environmental protection and energy saving, etc., and achieve the effect of long life and long durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

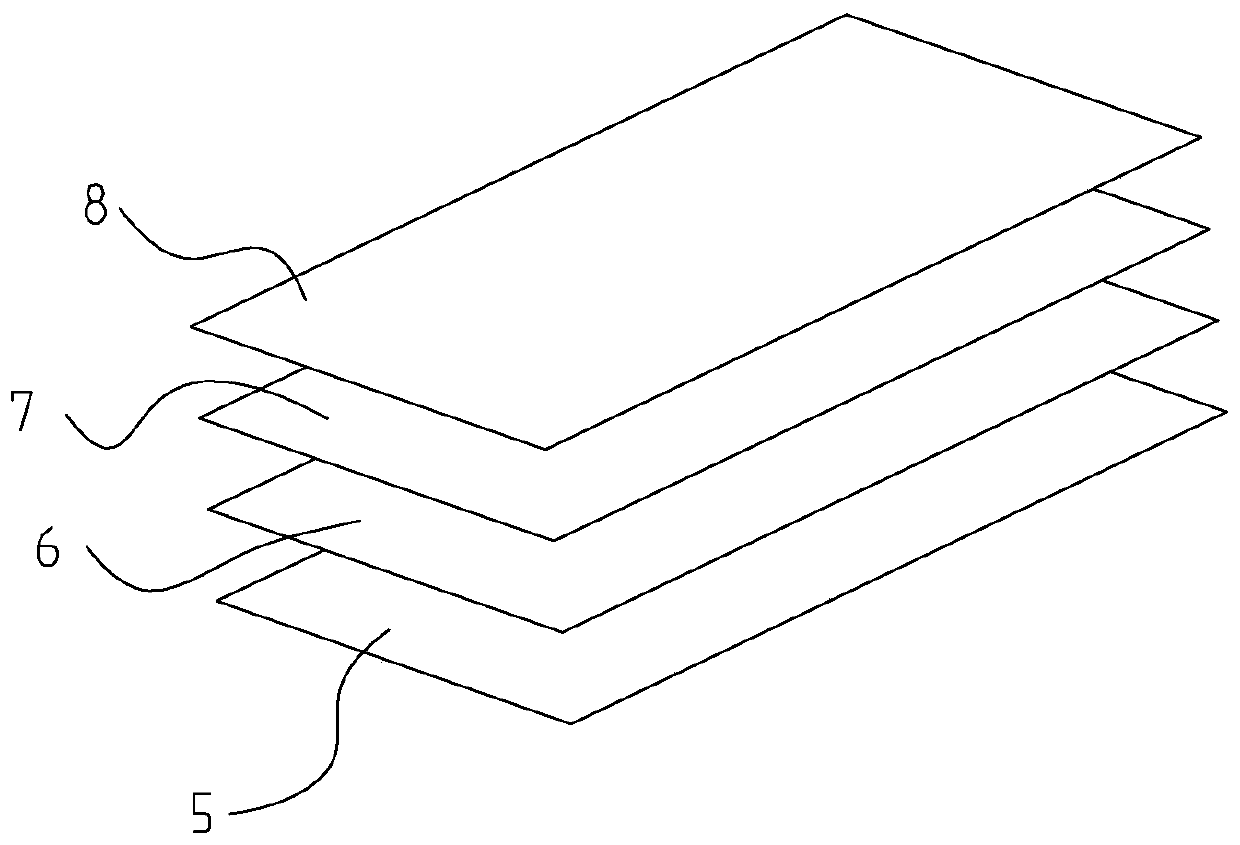

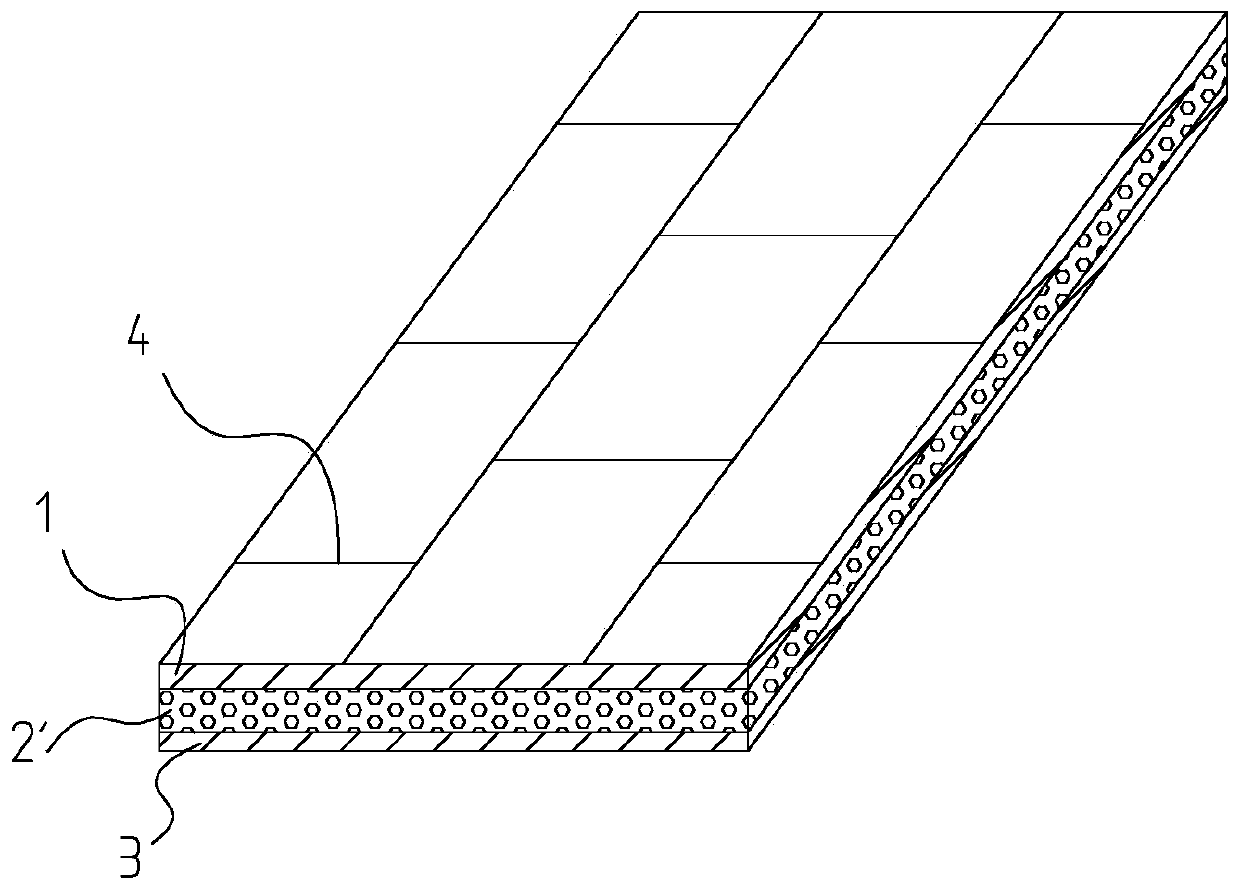

[0033] A thermal insulation PVC wallboard, characterized in that it includes a first substrate 1 and a second substrate 3, an insulating layer 2 is provided between the first base 1 and the second substrate 3, the first substrate 1 and the second substrate 3 The second substrate 3 is bonded and fixedly connected to both sides of the thermal insulation layer 2, adding a thermal insulation layer between the first substrate and the second substrate can play the role of thermal insulation; the upper surface of the first substrate 1 is provided with There is a printing layer 5, the upper surface of the printing layer 5 is provided with a foam layer 6, the upper surface of the foam layer 6 is provided with a protective layer 7, and the upper surface of the protective layer 7 is provided with a glass fiber reinforced plastic paint layer 8, the second A substrate serves as the outermost layer of the wallboard, and its surface is optimized for long-term durability and longer life.

[0...

Embodiment 2

[0038] The difference from Example 1 is that the thermal insulation layer 2 is a honeycomb panel. After the honeycomb panel is used, the wall panel has good thermal insulation performance, and the strength of the wall panel is also greatly enhanced, so that it has more excellent bending resistance. folding performance.

Embodiment 3

[0040] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the outer surface of the second substrate 3 is provided with a fluff layer 9, and there is an adhesive layer between the fluff layer 9 and the outer surface of the second substrate 3. 31. There are many gaps in the fluff layer, on the one hand, it can block the conduction of heat from the indoor to the second substrate or from the outside to the indoor through the second substrate; on the other hand, it can play a certain effect of sound insulation and noise reduction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com