Pipe gallery foundation pit assembly type integral translation supporting system and construction method

A supporting system and assembled technology, applied in infrastructure engineering, excavation, artificial islands, etc., can solve the problems of low construction efficiency, achieve good construction effect, high economic and social benefits, improve support construction efficiency and excavation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

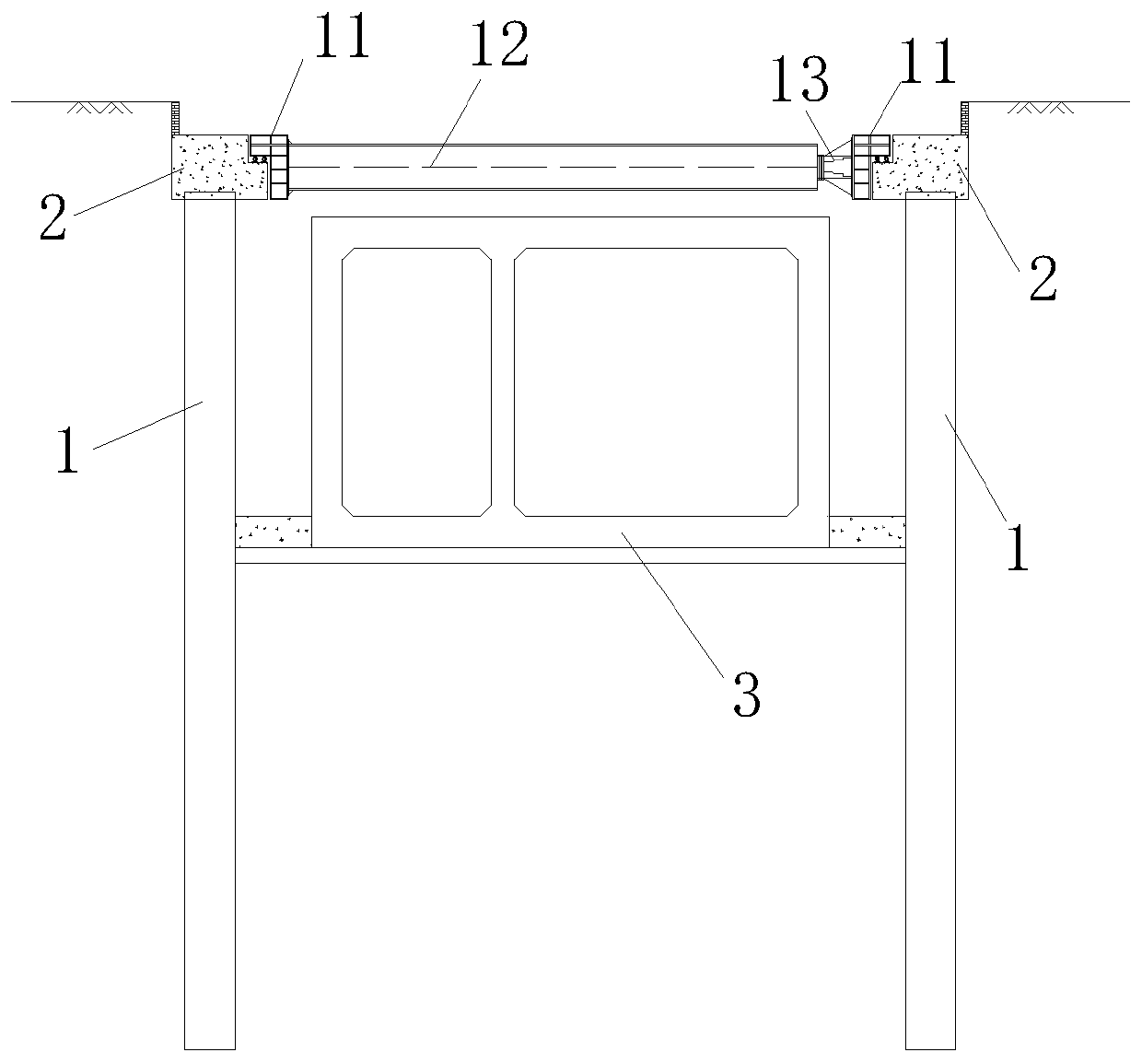

[0032] Combine figure 1 with figure 2 As shown, this embodiment provides an assembled integral translational support system for a pipe gallery foundation pit. An enclosure structure 1 is provided along the length direction on both sides of the pipe gallery foundation pit, and a top beam 2 is provided on the top of the enclosure structure 1. The pressure top beam 2 is provided with a concave platform along the length direction on the side close to the foundation pit. The supporting system includes a connecting beam 11, a steel support 12, a jack 13, a longitudinal guide rail 14 and a roller assembly 16.

[0033] Combine image 3 with Figure 4 As shown, the longitudinal guide rails 14 are arranged along the length of the concave platform, and the longitudinal guide rails 14 are provided with transverse positioning grooves 15 at intervals, and the transverse positioning grooves are used to realize the positioning of the roller assembly 16 under the pushing of the jack 13.

[0034] C...

Embodiment 2

[0042] This embodiment provides a construction method for a pipe gallery foundation pit, which adopts the assembled integral translation support system described in the first embodiment. The construction method will be further introduced below in conjunction with the drawings.

[0043] The construction method includes the following steps:

[0044] Step 1. Along the length of the pipe gallery, construct the enclosure 1 on both sides of the foundation pit and the top beam 2 with a concave platform on the top of the enclosure 1;

[0045] Step 2: Set the longitudinal guide rail 14 on the concave platform of the top beam 2; hoist the integral support frame composed of the connecting beam 11, the steel support 12, and the jack 13 in place, so that the roller assembly 16 under the flange of the connecting beam 11 is supported on On the longitudinal guide rail 14;

[0046] Step 3. Use the roller assembly 16 to move the integral support frame into position along the longitudinal guide rail 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com