Method for controlling molecular weight of dextran using composite gel microspheres

A dextran and composite gel technology, which is applied in the field of composite gel microspheres to control the molecular weight of dextran, can solve the problems of expanding the molecular weight distribution range of products, increasing the residence time of enzymes, and high viscosity of fermentation broth, so as to achieve controllable hydrolysis process and increase carbon source Utilization, effects of improving fermentation and purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

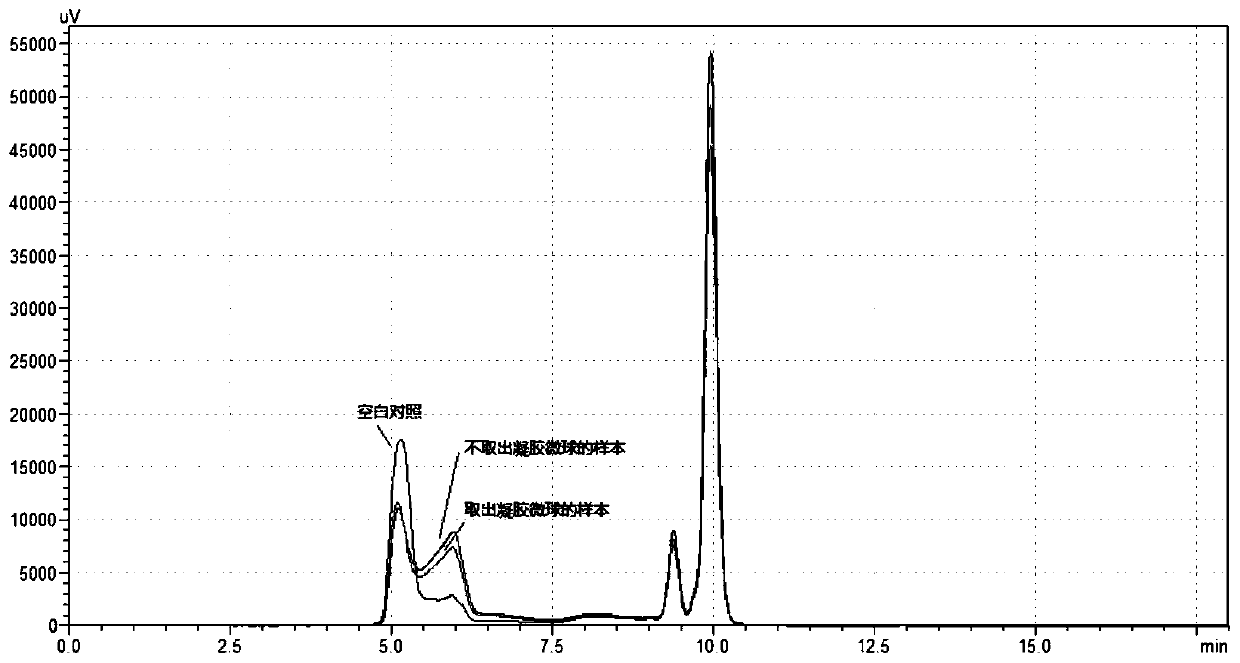

Embodiment 1

[0040] A method using composite gel microspheres to control the molecular weight of fermented dextran:

[0041] 1) Preparation of composite gel microspheres:

[0042] Sodium alginate, hydroxymethylcellulose and α-glucanase were dissolved in acetic acid-sodium acetate buffer at pH 5.6, and then the obtained sodium alginate solution, cellulose solution and α-glucan Mix the enzyme solution at a ratio of 0.2:0.4:0.015, add acetic acid-sodium acetate buffer solution to make up to the unit "1", stir for 5 minutes, then add 16% calcium chloride solution containing 0.5% glutaraldehyde dropwise, and let it stand for The gel was fixed for 45 minutes, and the microspheres were filtered out to obtain the composite gel microspheres, and the enzyme recovery rate was 90.5%;

[0043] Wherein, the viscosity of hydroxymethylcellulose is 500~3000, and the concentration of α-glucanase solution is 8000~12000 IU / mL;

[0044] 2) Prepare seed medium: sucrose 101.31 g / L, peptone 5.66 g / L, disodium h...

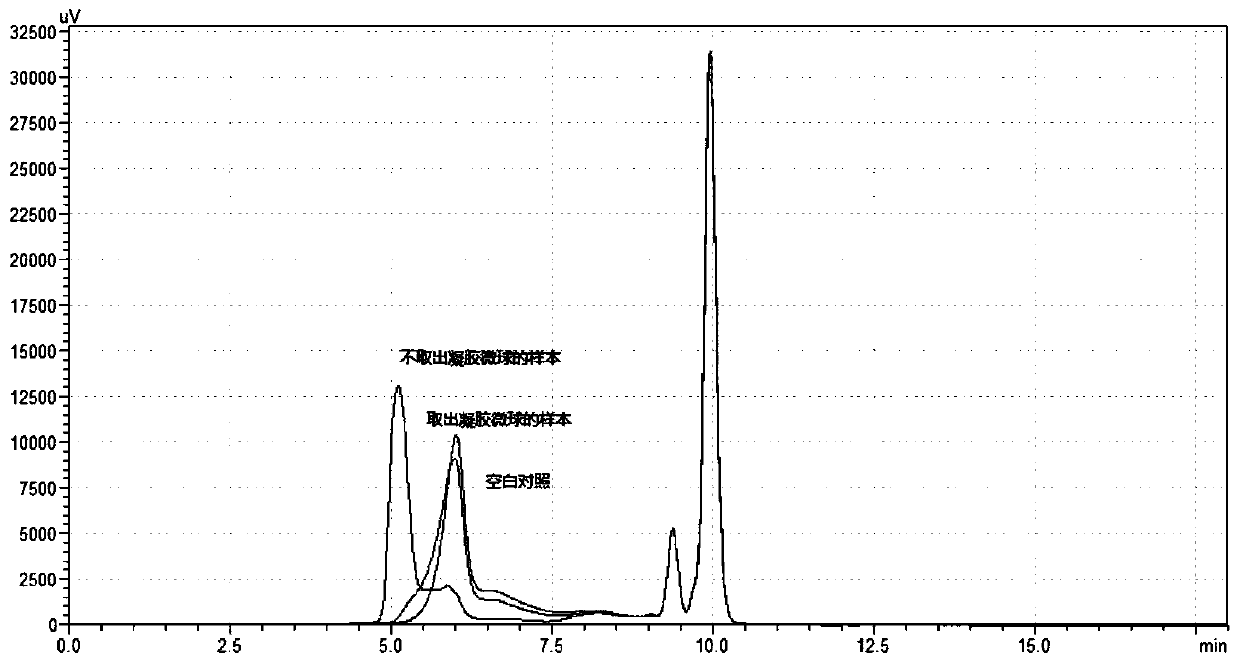

Embodiment 2

[0051] A method using composite gel microspheres to control the molecular weight of fermented dextran:

[0052] 1) Preparation of composite gel microspheres:

[0053] Sodium alginate, hydroxymethylcellulose and α-glucanase were dissolved in acetic acid-sodium acetate buffer at pH 5.6, and then the obtained sodium alginate solution, cellulose solution and α-glucan Mix the enzyme solution at a ratio of 0.25:0.5:0.05, add acetic acid-sodium acetate buffer solution to make up to the unit "1", stir for 5-15min, then add 12% calcium chloride solution containing 0.25% glutaraldehyde dropwise, static Place and fix the gel for 45min, filter and filter out the microspheres to obtain the composite gel microspheres, and the enzyme recovery rate is 93.5%;

[0054] Wherein, the viscosity of hydroxymethylcellulose is 500~3000, and the concentration of α-glucanase solution is 8000~12000 IU / mL;

[0055] 2) Prepare seed medium: 101.31 g / L sucrose, 5.66 g / L peptone, 1.11 g / L disodium hydrogen ...

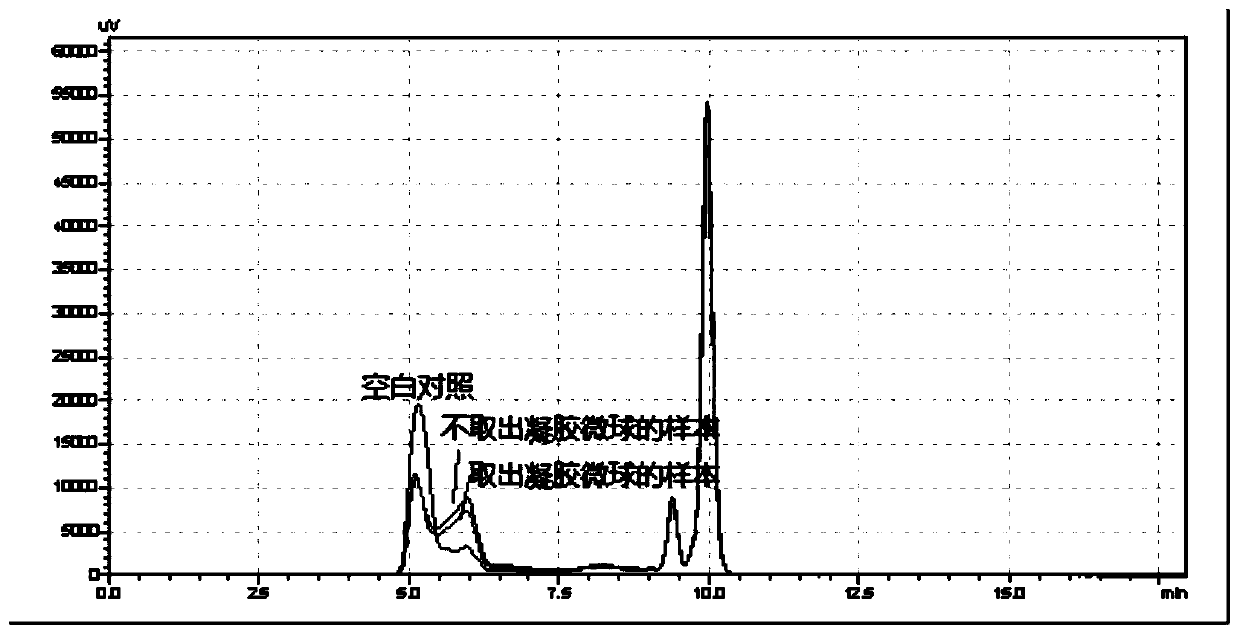

Embodiment 3

[0063] A method using composite gel microspheres to control the molecular weight of fermented dextran:

[0064] 1) Preparation of composite gel microspheres:

[0065] Sodium alginate, hydroxymethylcellulose and α-glucanase were dissolved in acetic acid-sodium acetate buffer at pH 5.6, and then the obtained sodium alginate solution, cellulose solution and α-glucan Mix the enzyme solution at a ratio of 0.2:0.5:0.025, add acetic acid-sodium acetate buffer solution to make up to the unit "1", stir for 10 minutes, then add 8% calcium chloride solution containing 0.25% glutaraldehyde dropwise, let stand The gel was fixed for 40 minutes, and the microspheres were filtered out to obtain the composite gel microspheres, and the enzyme recovery rate was 83.2%;

[0066] Wherein, the viscosity of hydroxymethylcellulose is 500~3000, and the concentration of α-glucanase solution is 8000~12000 IU / mL;

[0067] 2) Prepare seed medium: sucrose 101.31 g / L, peptone 5.66 g / L, disodium hydrogen ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com