Quartz sand conveying device and method

A conveying device, quartz sand technology, applied in conveyor objects, transportation and packaging, loading/unloading, etc., can solve the problems of unstable quartz sand flow, safety risks, quartz sand pollution, etc., to ensure stability and product quality. , The effect of reducing safety risks and stabilizing delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

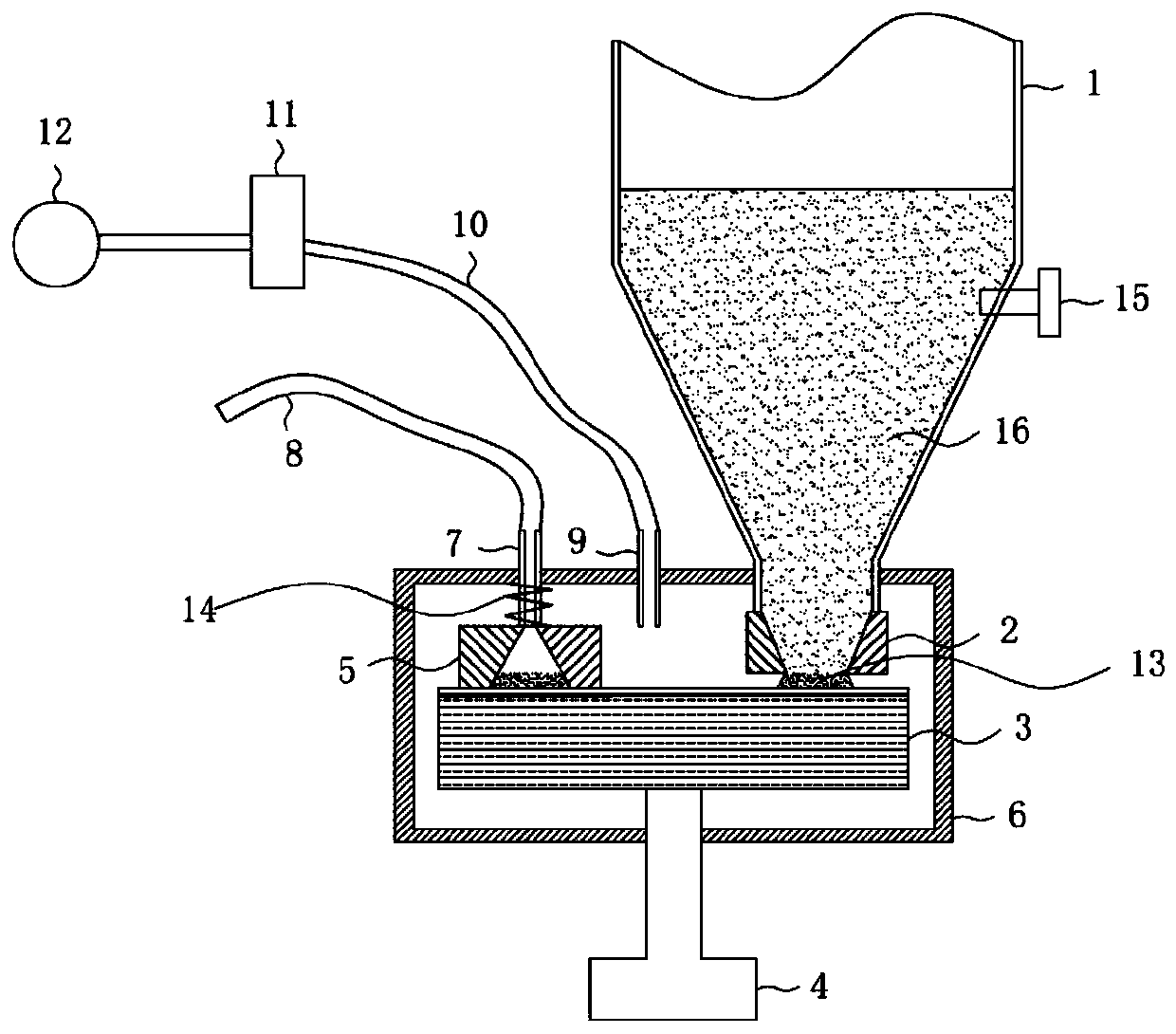

[0073] A quartz sand feeding device proposed by an embodiment of the present invention consists of a storage bin 1, a feeding block 2, a transfer plate 3, a rotary drive system 4, a blowing block 5, a sealing bin 6, a material output port 7, a material Consists of a delivery pipeline 8, a gas input port 9, a gas input pipeline 10, a flow meter 11, a pressure controller 12, and a position sensor 15. The blanking block 2, the transfer plate 3, and the blowing block 5 are located in the sealed bin 6, the storage bin 1, the rotary drive system 4, the material output port 7, the gas input port 9 and the sealed bin 6 are sealed connections, and the sealed bin 6 The gas is not connected to the outside world. Driven by the rotary drive system 4 , the transmission disc 3 can rotate along its own rotating shaft. The blanking block 2 is fixed above the conveying tray 3, the outlet of the blanking block 2 maintains a fixed gap with the conveying tray 3, and the blanking block 2 is connec...

Embodiment 2

[0078] A quartz sand feeding device proposed by an embodiment of the present invention consists of a storage bin 1, a feeding block 2, a transfer plate 3, a rotary drive system 4, a blowing block 5, a sealing bin 6, a material output port 7, a material Consists of a delivery pipeline 8, a gas input port 9, a gas input pipeline 10, a flow meter 11, a pressure controller 12, a pressurizing device 14, and a position sensor 15. The blanking block 2, the transfer plate 3, and the blowing block 5 are located in the sealed bin. The storage bin 1, the rotary drive system 4, the material output port 7, the gas input port 9 and the sealed bin 6 are hermetically connected, and the gas in the sealed bin 6 Not connected with the outside world. Driven by the rotary drive system 4 , the transmission disc 3 can rotate along its own rotating shaft. The blanking block 2 is fixed above the conveying tray 3, the outlet of the blanking block 2 maintains a fixed gap with the conveying tray 3, and ...

Embodiment 3

[0084] A quartz sand feeding device proposed by an embodiment of the present invention consists of a storage bin 1, a feeding block 2, a transfer plate 3, a rotary drive system 4, a blowing block 5, a sealing bin 6, a material output port 7, a material Consists of a delivery pipeline 8, a gas input port 9, a gas input pipeline 10, a flow meter 11, a pressure controller 12, and a position sensor 15. The blanking block 2, the transfer plate 3, and the blowing block 5 are located in the sealed bin. The storage bin 1, the rotary drive system 4, the material output port 7, the gas input port 9 and the sealed bin 6 are hermetically connected, and the gas in the sealed bin 6 Not connected with the outside world. Driven by the rotary drive system 4 , the transmission disc 3 can rotate along its own rotating shaft. The blanking block 2 is fixed above the conveying tray 3, the outlet of the blanking block 2 maintains a fixed gap with the conveying tray 3, and the blanking block 2 is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com