Stress-free clamping method for datum plane machining of open thin-walled part

A thin-walled parts, stress-free technology, applied in metal processing equipment, metal processing machinery parts, clamping, etc., can solve processing and other problems, achieve the effect of improving rigidity, ensuring processing accuracy, and suppressing milling chatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

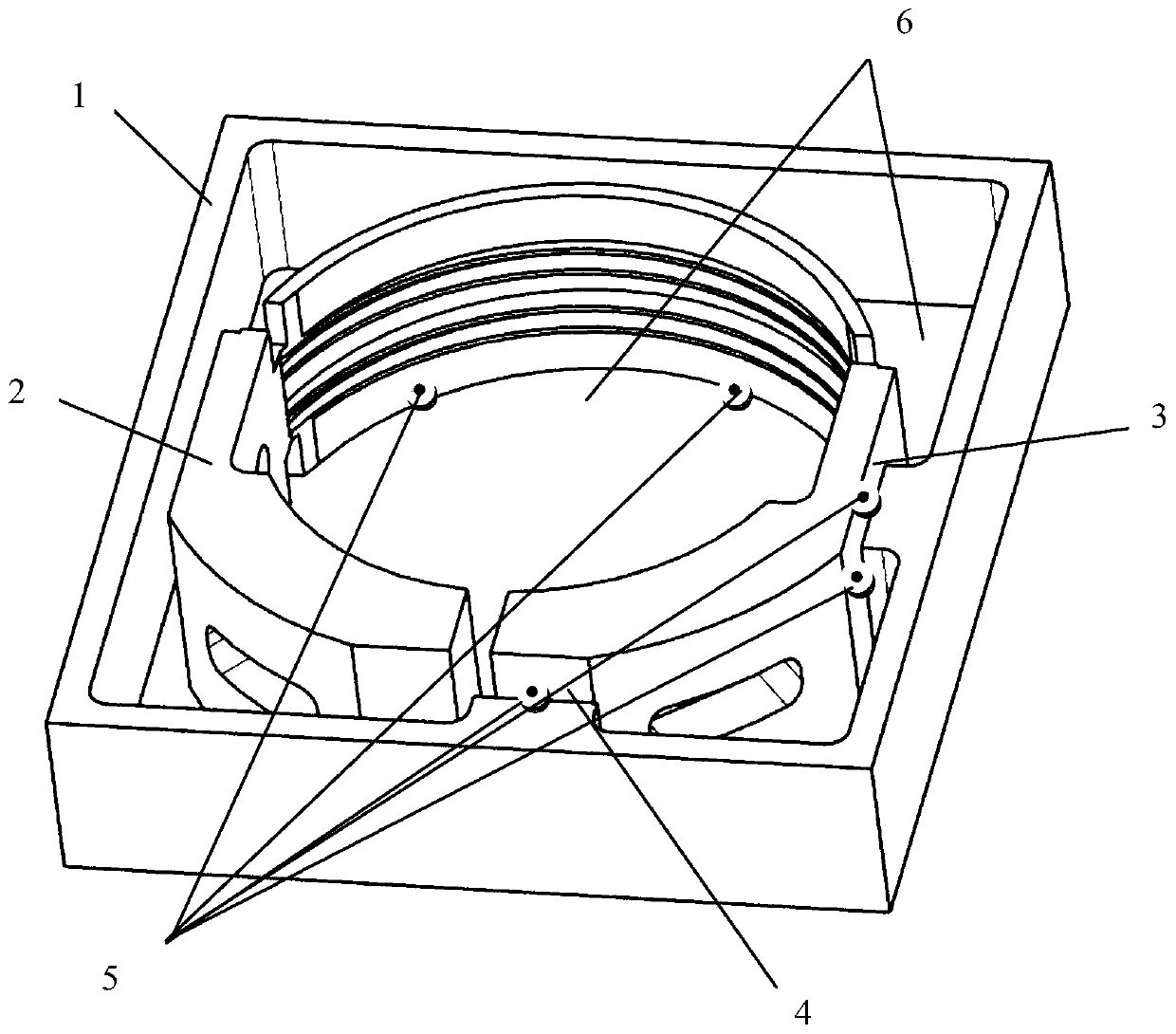

[0023] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0024] Technical scheme of the present invention is as follows:

[0025] 1) Clamping elements

[0026] The invention includes the following clamping elements: base, hot-melt glue, and low melting point alloy.

[0027] 2) Clamping principle

[0028] The base is the basic element of the clamping method, and it is the intermediate body between the open thin-walled parts and the vise fixture of the machine tool. Its main function is to provide reference positioning and workpiece support for the open thin-walled parts, and at the same time as a filling pool for low melting point alloys;

[0029] Hot melt adhesive is an important element in the clamping method. It is used to limit the position of the open thin-walled parts in the base, and prevent the impact and flow of the low-melting alloy solution from causing the parts to be out of position, which in turn causes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com