Tandem type multi-spindle machining center and numerical control machining method

A machining center, multi-spindle technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve problems such as low production efficiency, and achieve the effect of increasing output and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

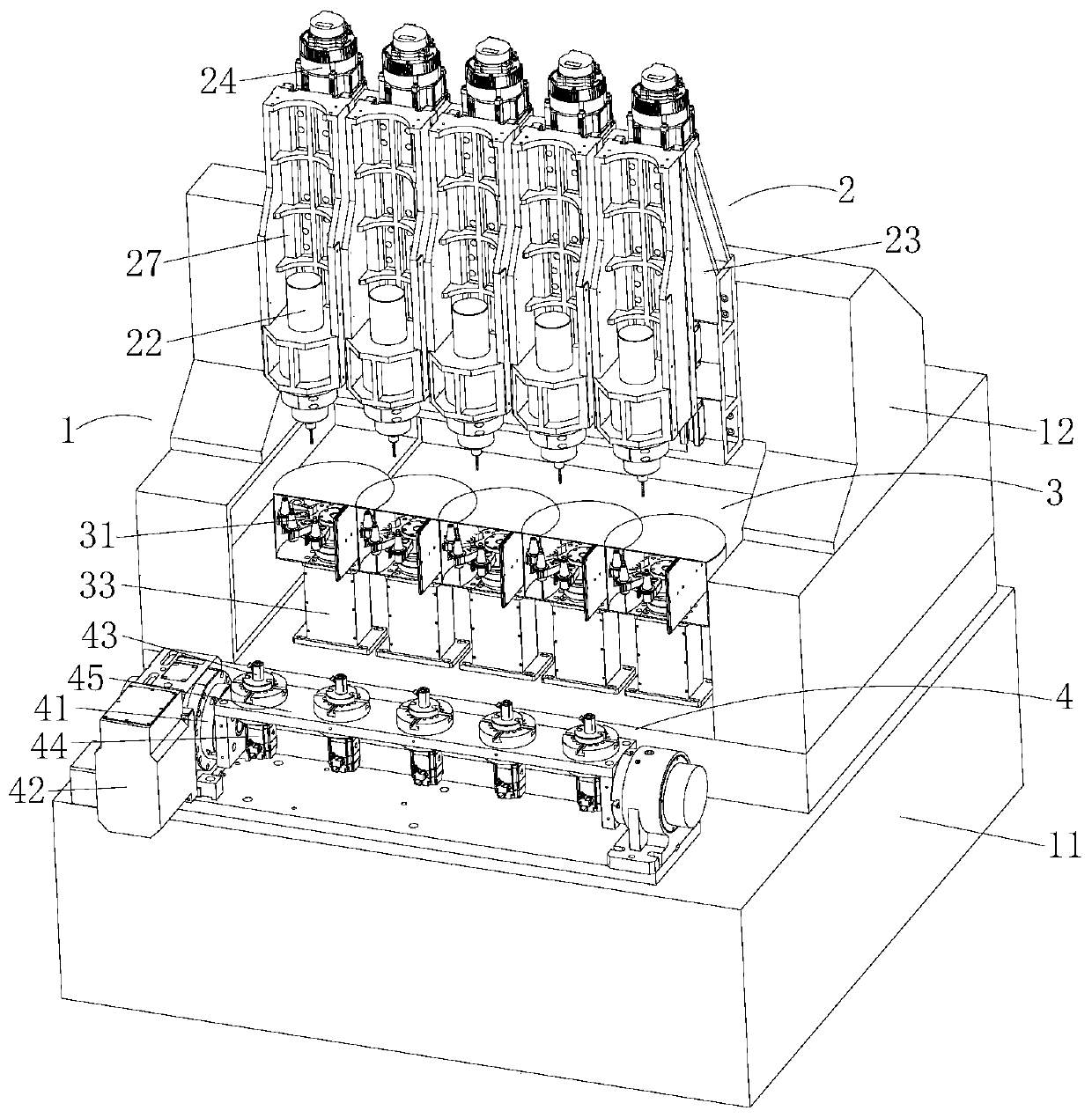

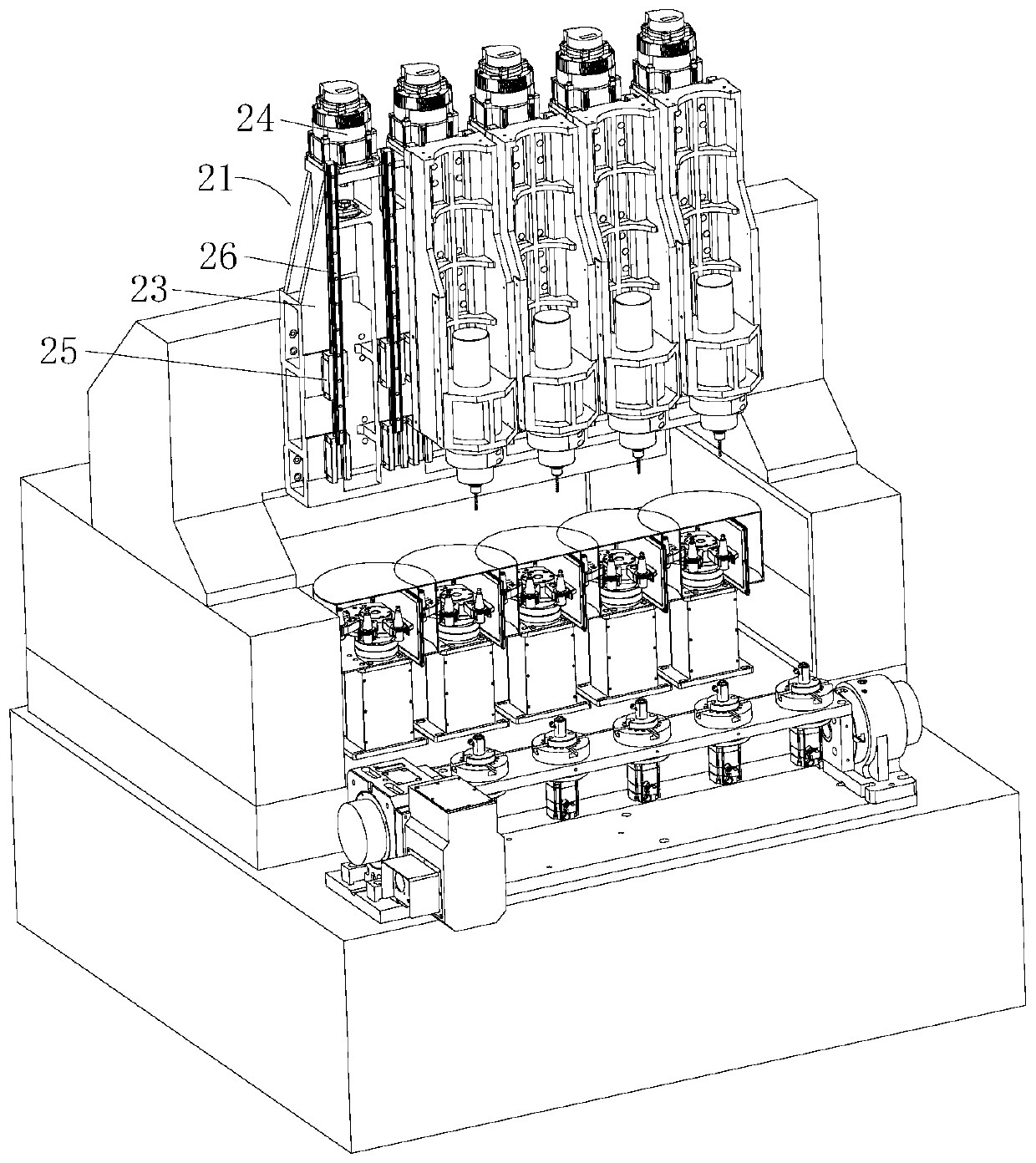

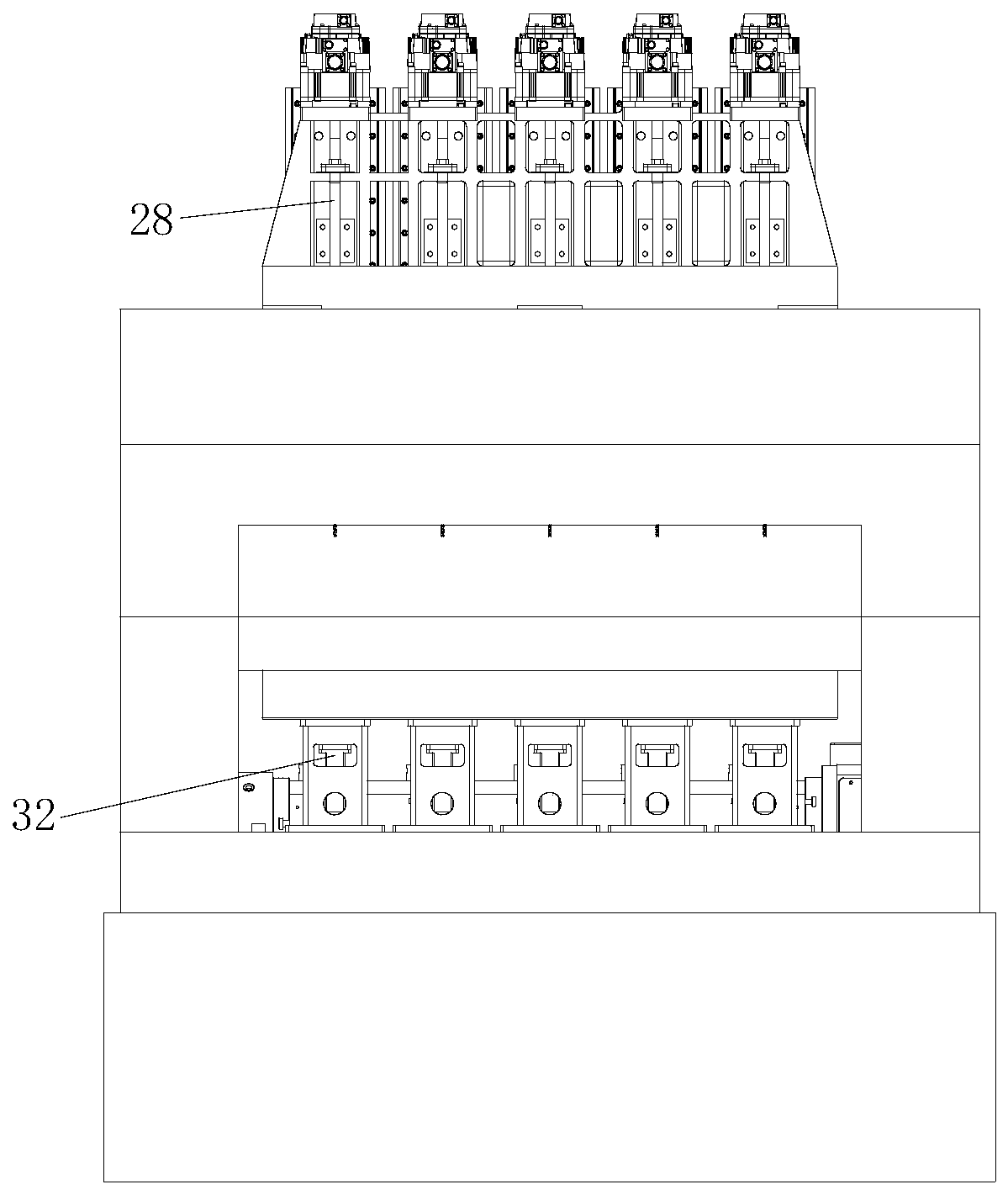

[0024] Such as Figure 1-3 As shown, a tandem multi-spindle machining center includes a frame 1, at least two spindle devices 2 installed side by side on the frame for installing fixed tools, and at least two parallel mounted on the frame 1 And with the tool magazine device 3 installed under the spindle device 2 corresponding to the spindle device 2 one-to-one, installed on the frame 1 and one-to-one with the spindle device 2, it is applied to the work of placing workpieces Table device 4. The present invention arranges a plurality of spindle devices 2, each spindle device 2 corresponds to a tool magazine device 3 and a workbench device 4, each spindle device 2 operates independently, and the equipment can process multiple workpieces at a time. After the machining process, the entire series-connected spindle device 2 can perform tool changing actions at the same time, effectively improving the output per unit time of the equipment and greatly improving production efficiency. ...

Embodiment 2

[0033] A kind of numerical control processing method, comprises the following steps,

[0034] (1) Place a plurality of workpieces to be processed on corresponding jigs 43 respectively, and the rotating shaft drive motor 42 drives the rotating shaft 41 to rotate to the corresponding position, driving the workpieces to reach the corresponding position and wait for processing;

[0035] (2) on each main shaft 22, according to machining requirement, corresponding tool is installed, and each longitudinal drive motor 24 drives corresponding main shaft 22 to move downwards simultaneously, and workpiece is processed simultaneously;

[0036] (3) After the processing is completed, the longitudinal drive motor 24 drives the corresponding main shaft 22 to move upwards simultaneously, and multiple main shafts 22 perform tool changing actions at the same time.

[0037] The present invention uses multiple spindles 22 to simultaneously process multiple workpieces such as drilling, tapping, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com