An automatic heat insulating glass side edge sealing equipment

A technology of edge sealing equipment and heat insulating glass, which is applied to the device and coating of the surface coating liquid, which can solve the problems of uneven coating uniformity and low efficiency, and achieve the effect of avoiding uneven coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

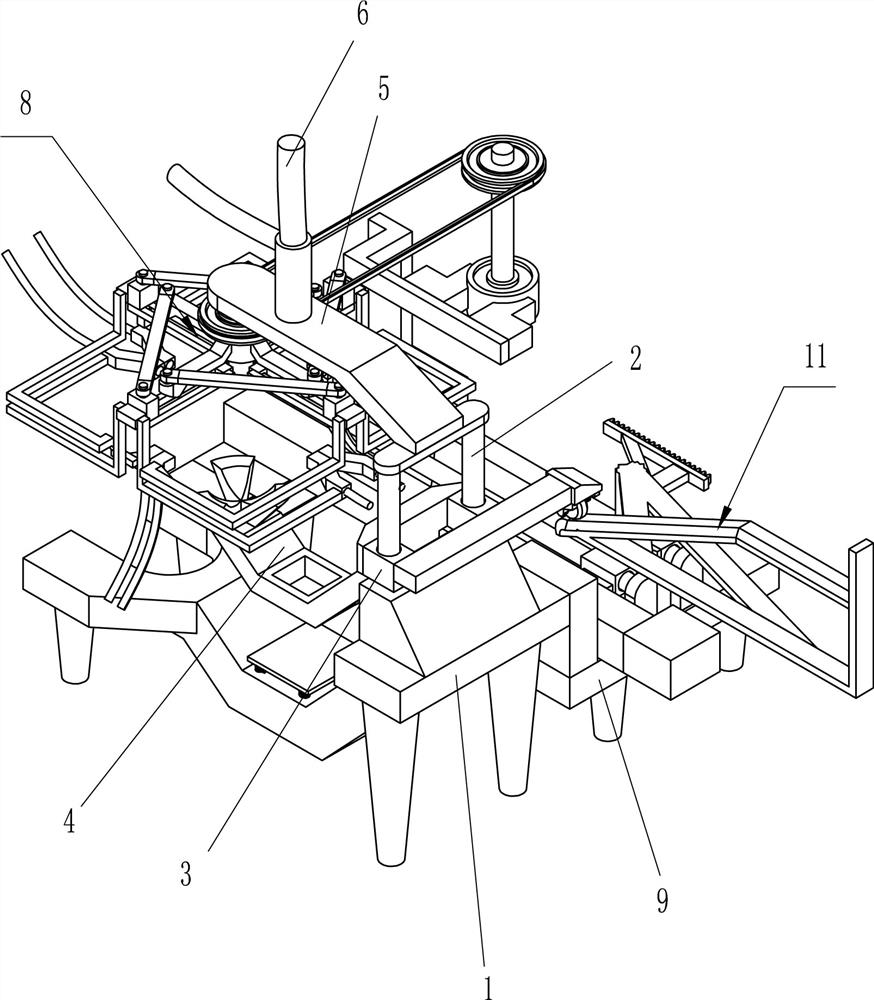

[0025] An automatic heat insulating glass side edge sealing equipment, such as Figure 1-3 As shown, it includes a mounting frame 1, a first guide rail 2, a first guide sleeve 3, a placement frame 4, a connecting plate 5, an external connection pipe 6, a fixing rod 7, a gluing device 8, a bracket 9 and a pushing device 10, and the placement frame 4 is used to place the insulating insulating glass, the external connection pipe 6 is used to connect the external glue and supply glue to the equipment, the gluing device 8 is used to apply glue to the side of the glass, and the pushing device 10 is used to drive the gluing device 8, specifically for:

[0026] One side of the mounting bracket 1 is connected with a first guide rail 2, the first guide rail 2 is slidably connected with a first guide sleeve 3, one side of the first guide sleeve 3 is connected with a placement frame 4, and the placement The frame 4 is located above the mounting frame 1, one side of the placing frame 4 is...

Embodiment 2

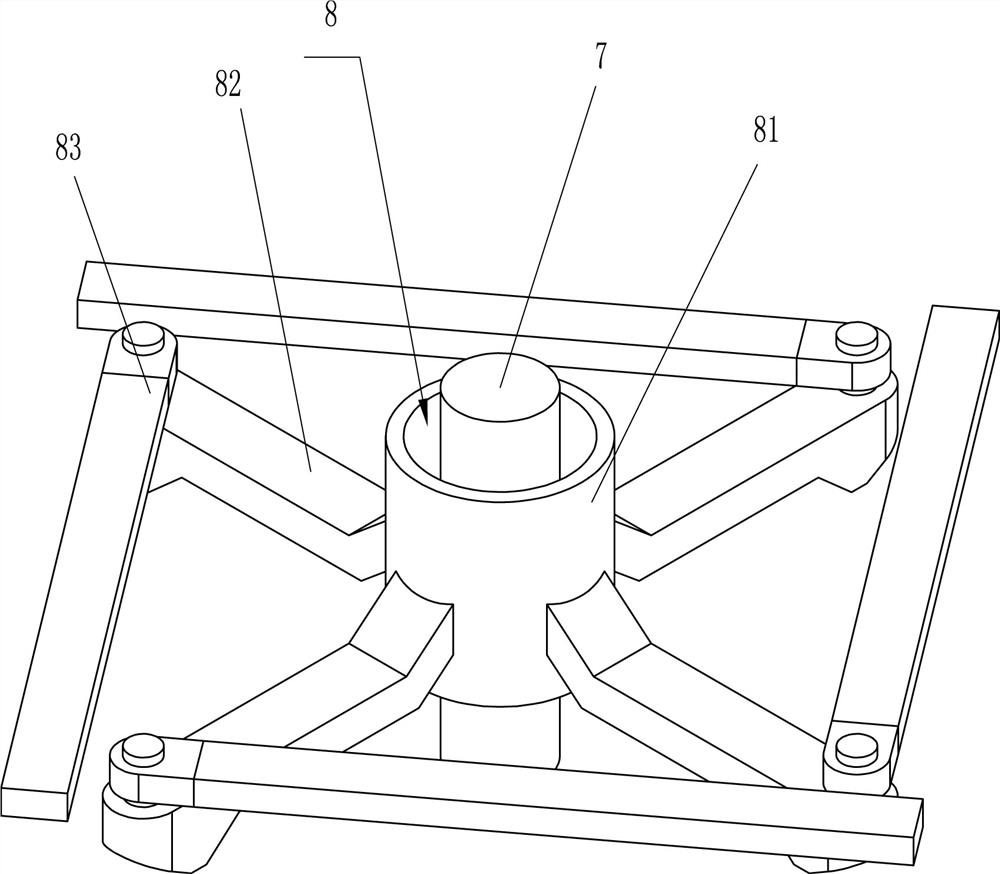

[0029] On the basis of Example 1, such as Figure 4-5 As shown, the gluing device 8 includes a rotating ring 81, a rotating arm 82, a push rod 83, a second guide rail 84, a second guide sleeve 85, a moving rod 86, a connecting block 87, a connecting rod 88, and a glue outlet 89 And the flexible pipe 810, the rotating ring 81 is used to be driven and rotated by the pushing device 10, the rotating arm 82 can rotate, the push rod 83 is used for pushing, and the moving rod 86 is used to be pushed by the rotating arm 82 and the push rod 83 to make a linear movement, connecting The rod 88 is used for linear movement, the glue outlet head 89 is used for applying glue to the side of the glass, and the hose 810 is used for conveying glue, specifically:

[0030] The fixed rod 7 is rotatably connected with a rotatable ring 81, the rotatable ring 81 is connected with the pushing device 10, four sets of rotatable arms 82 are arranged on the outside of the rotatable ring 81, and the upper s...

Embodiment 3

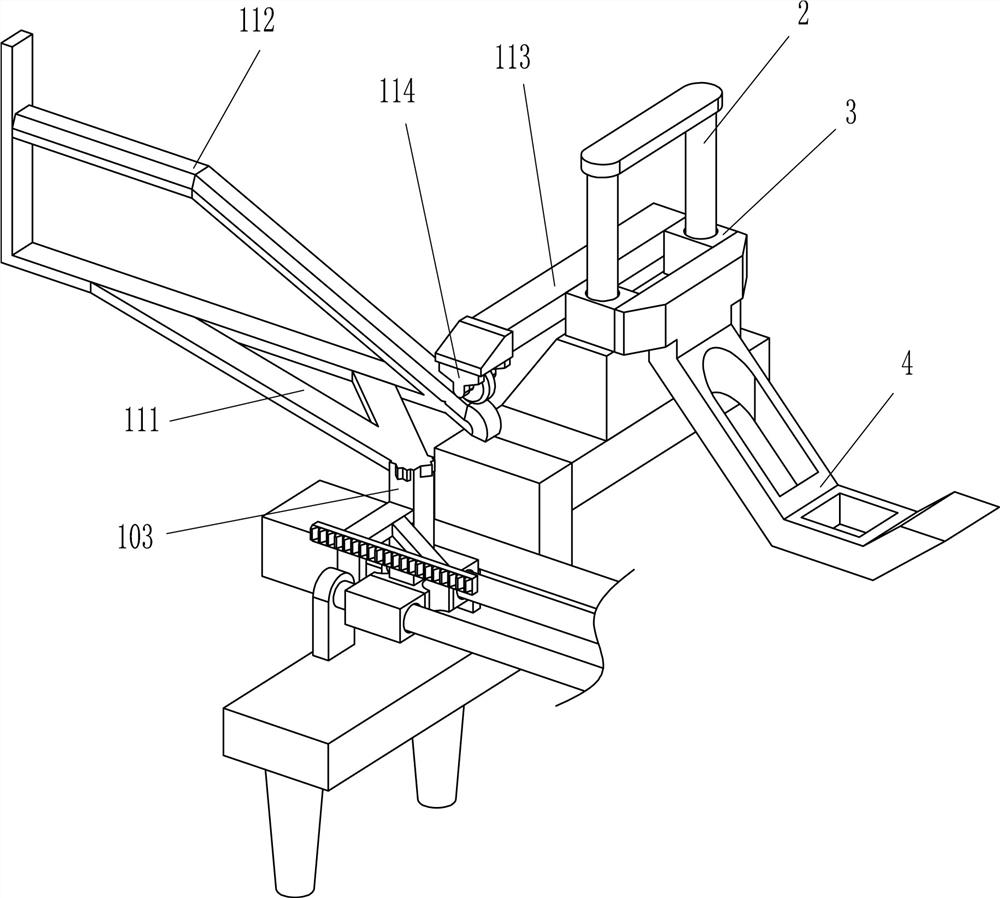

[0037] On the basis of Example 2, such as Figure 7 As shown, a lifting device 11 is also included, and the moving block 103 is provided with the lifting device 11. The lifting device 11 includes a fixed frame 111, a moving track 112, an extension rod 113 and a roller 114, specifically:

[0038] The upper side of the moving block 103 is connected with a fixed frame 111, the fixed frame 111 is connected with a moving track 112, and the side of the first guide sleeve 3 away from the placement frame 4 is connected with an extension rod 113, and the extension rod 113 is close to A roller 114 is connected to one side of the moving block 103 , and the roller 114 is in contact with the moving track 112 .

[0039] In the specific operation of the above embodiment, when the moving block 103 moves, the moving block 103 will drive the fixed frame 111 and the moving track 112 to move, so that the moving track 112 drives the rollers 114 moves upward, so that the roller 114 drives the exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com