Vegetable protein sausages capable of effectively reducing beany flavor and bitter flavor, and preparation method of vegetable protein sausages capable of effectively reducing beany flavor and bitter flavor

A technology of plant protein and bean flavor, which is applied in food science, food ingredients containing natural extracts, food ingredients as odor improvers, etc., can solve the problems of plant protein intestinal fishy smell and bitter taste that are difficult to remove and cover, and achieve Effect of reducing beany and bitterness, lasting fragrance and umami, and removing bitterness and beany

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

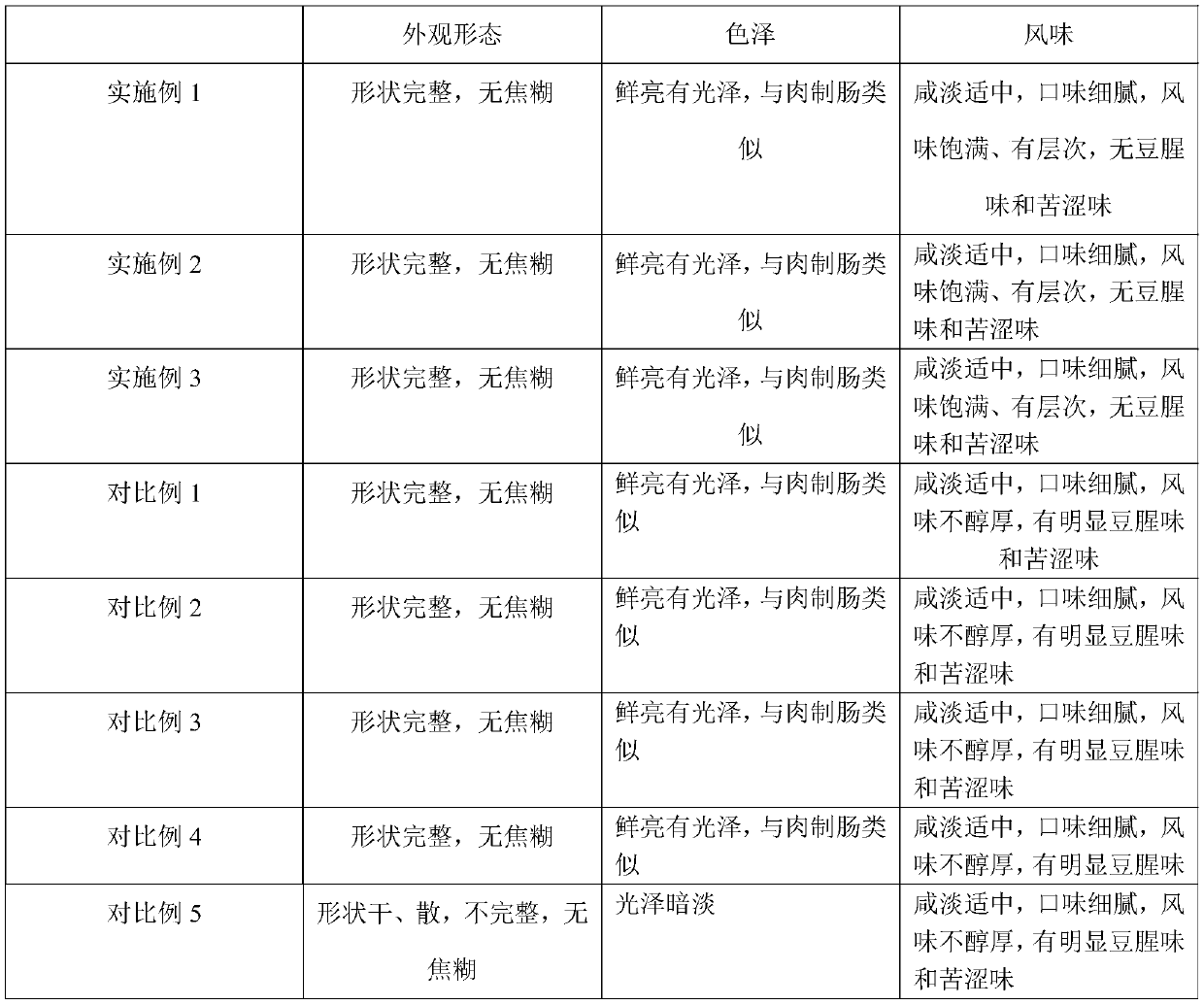

Examples

Embodiment 1

[0049] A vegetable protein intestine that can effectively reduce the beany taste and bitterness. In parts by weight, it is made from the following raw materials: 10 parts of vegetable isolate protein, 16 parts of vegetable drawing protein, 7 parts of vegetable oil, 1.2 parts of edible salt, natural Color 0.08 part, compound enzyme preparation 0.3 part, compound thickener 0.1 part, compound spice material 0.3 part, compound sweetener 2 part, compound umami flavor agent 0.3 part, food flavor 0.5 part, modified starch 10 part , 48 parts of ice water; wherein the plant protein isolate and plant silky protein are made from soybeans, peas, wheat, and rice with a mass ratio of 1:0.3:0.1:0.2; the compound enzyme preparation is Cathepsin and aminopeptidase are mixed according to a mass ratio of 1:0.5; the compound sweetener is a compound of white sugar, licorice extract and glucosyl steviol glycosides in a mass ratio of 1:0.03:0.06; The compound umami agent is prepared by mixing I+G and...

Embodiment 2

[0083] A vegetable protein intestine that can effectively reduce the beany taste and bitterness. In parts by weight, it is made from the following raw materials: 14 parts of vegetable isolate protein, 12 parts of vegetable drawing protein, 9 parts of vegetable oil, 0.8 parts of edible salt, natural 0.12 part of pigment, 0.1 part of compound enzyme preparation, 0.3 part of compound thickener, 0.1 part of compound spice, 3 parts of compound sweetener, 0.1 part of compound umami, 1.5 parts of food flavor, 7 parts of modified starch , 56 parts of ice water; wherein the plant protein isolate and plant silky protein are made from soybeans, peas, wheat and rice with a mass ratio of 1:0.2:0.2:0.1; the compound enzyme preparation is Cathepsin and aminopeptidase are mixed and prepared according to a mass ratio of 1:0.6; the compound sweetener is a compound of white sugar, licorice extract and glucosyl stevioside in a mass ratio of 1:0.02:0.1; The compound umami agent is prepared by mixin...

Embodiment 3

[0117] A vegetable protein intestine that can effectively reduce the beany taste and bitterness. It is made from the following raw materials in parts by weight: 12 parts of vegetable isolate protein, 14 parts of vegetable drawing protein, 8 parts of vegetable oil, 1 part of edible salt, natural 0.1 part of pigment, 0.2 part of compound enzyme preparation, 0.2 part of compound thickener, 0.2 part of compound spice, 2.5 part of compound sweetener, 0.2 part of compound umami, 1 part of food flavor, 9 parts of modified starch , 50 parts of ice water; wherein the plant protein isolate and plant silky protein are made from soybeans, peas, wheat, and rice with a mass ratio of 1:0.25:0.15:0.15; the compound enzyme preparation is Cathepsin and aminopeptidase are mixed and prepared according to a mass ratio of 1:0.55; the compound sweetener is compounded by mixing white sugar, licorice extract and glucosyl steviol glycoside in a mass ratio of 1:0.025:0.08; The compound umami agent is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com