All-vanadium redox flow battery electrolyte formula and process for maintaining high performance of electrolyte

A technology of all-vanadium redox flow battery and electrolyte, which is applied in the field of electrolyte formula and technology of all-vanadium redox flow battery, and can solve the problems that have not yet been qualitatively and quantitatively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

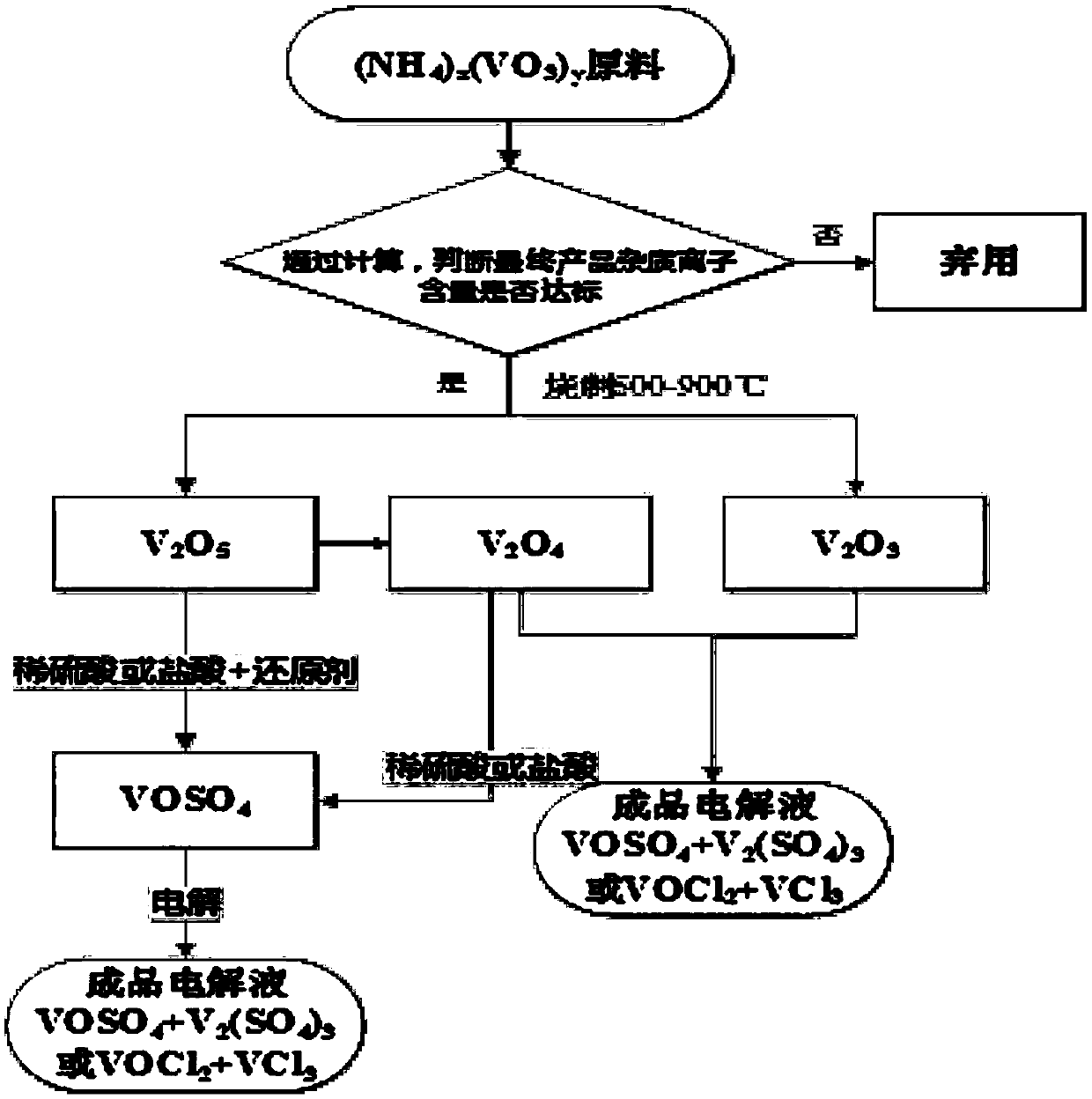

Image

Examples

Embodiment 1

[0070] The electrolyte solution was prepared and operated according to the content of the experimental sample and the control sample in the following table, and the results obtained are shown in the following table:

[0071]

[0072]

[0073] The above data and operation results show that after properly amplifying the concentration of the above six types of organic C elements, this experiment uses H 2 SO 4 The system electrolyte, 2kW battery, has experienced more than 170 cycles. Compared with the control sample, the system efficiency of the high-purity vanadium electrolyte battery has no significant change, indicating that the organic C element is properly released, and has no effect on the system discharge capacity and efficiency.

Embodiment 2

[0075] The electrolyte solution was prepared and operated according to the content of the experimental sample and the control sample in the following table:

[0076]

[0077]

[0078] The running results are shown in the table below:

[0079]

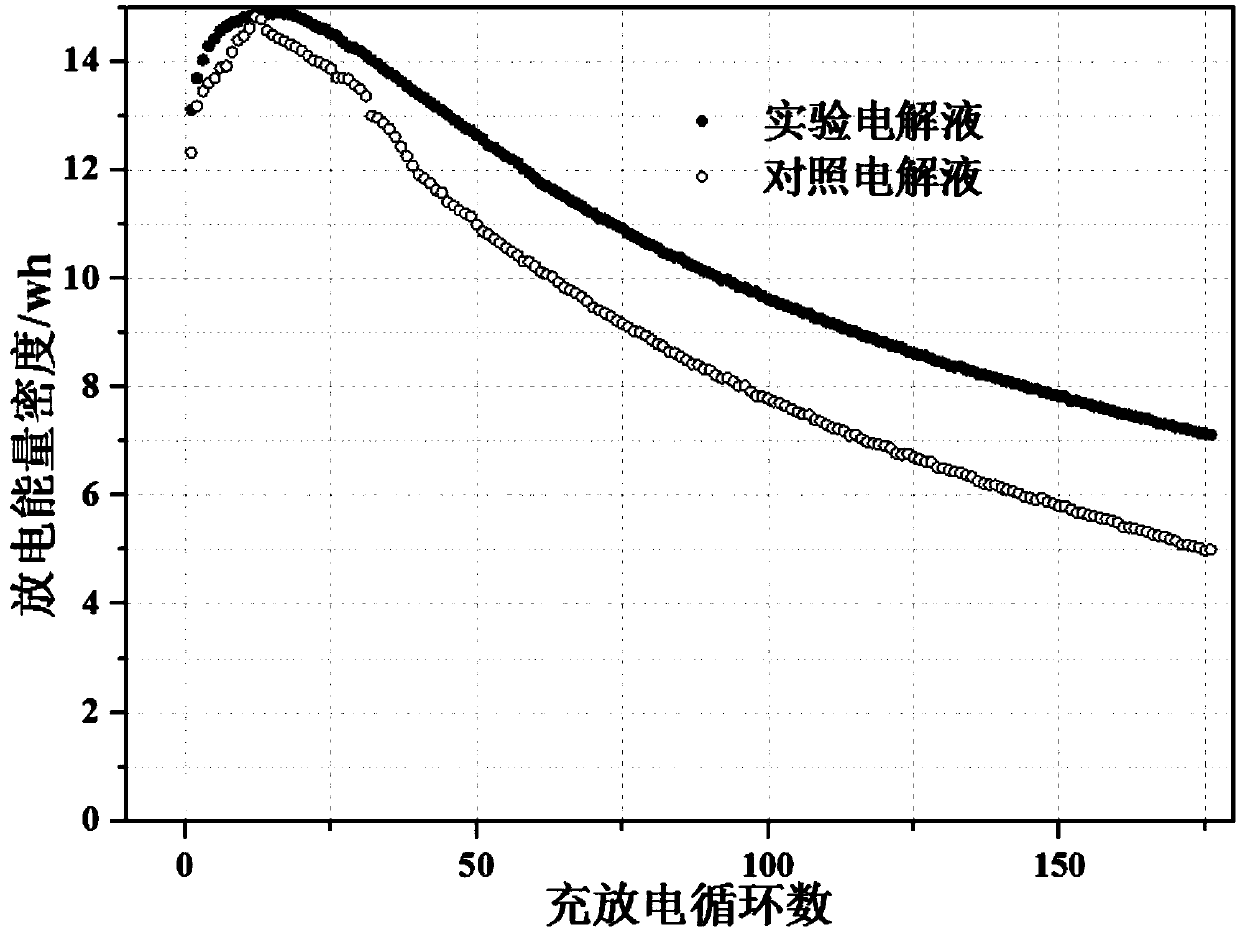

[0080] The above data and operation results show that the experimental sample H after appropriately amplifying the concentration of the above six types of organic C elements 2 SO 4 System electrolyte, compared with the control electrolyte with a large residual organic C element, using a 10kW battery, after more than 170 cycles, the system efficiency of the experimental electrolyte is better than that of the control electrolyte, and the system discharge capacity decays significantly in the experimental electrolyte better than the control electrolyte.

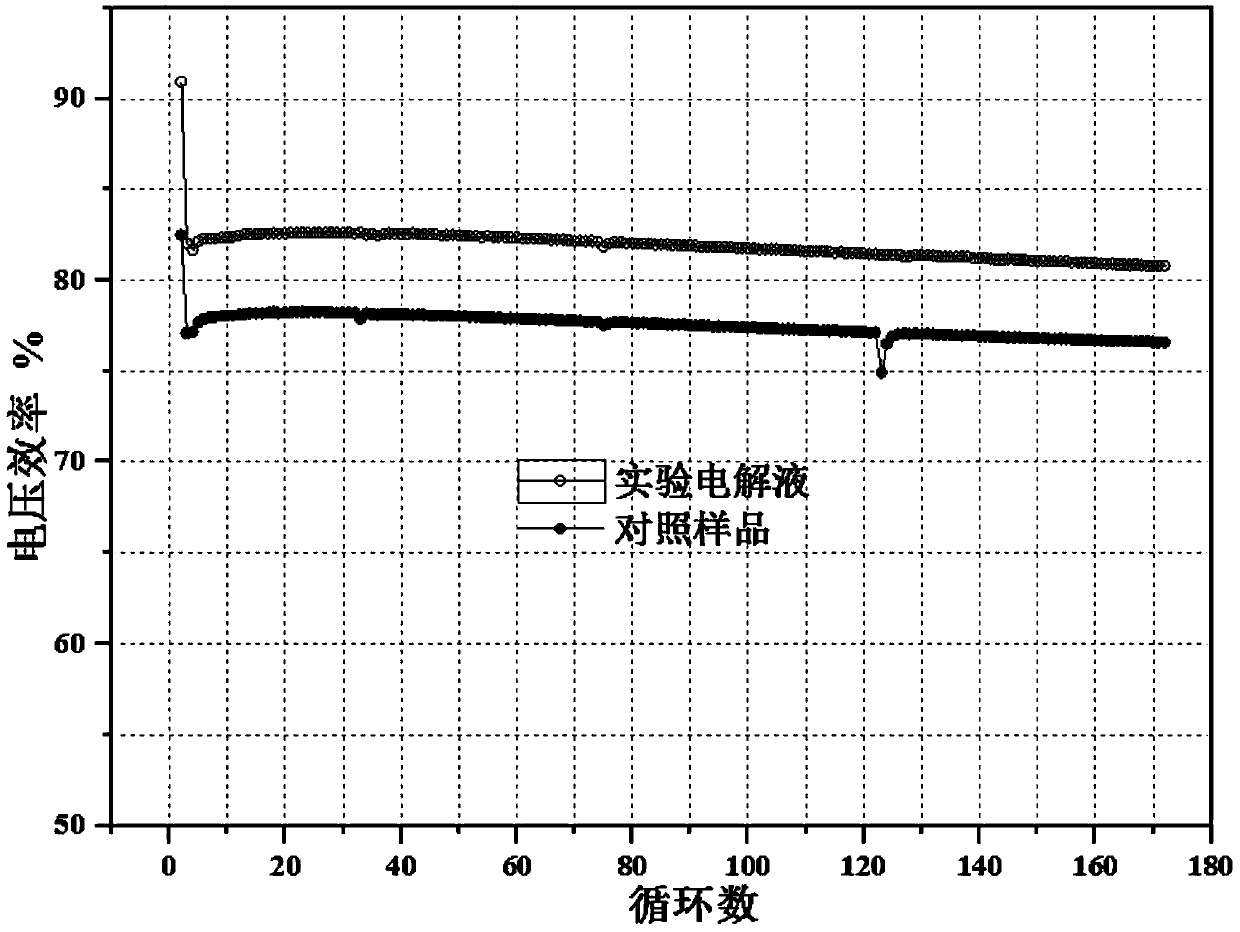

[0081] Depend on Figure 2-3 It can be seen from the middle curve that the voltage efficiency of the experimental sample electrolyte is 4 percentage points higher than that of ...

Embodiment 3

[0083] The electrolyte solution was prepared and operated according to the content of the experimental sample and the control sample in the following table:

[0084]

[0085]

[0086] The running results are shown in the table below:

[0087]

[0088] The above data and operation results show that the experimental sample H after appropriately amplifying the concentration of the above six types of organic C elements 2 SO 4 System electrolyte, compared with the control electrolyte with a large residual organic C element, using a 30kW battery, after more than 170 cycles, the efficiency of the experimental electrolyte system is significantly better than that of the control electrolyte system, and the system discharge capacity decay experiment The electrolyte was significantly better than the control electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com