A cuprous oxide film and its application in fuel cells

A cuprous oxide and fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high cost of platinum-based catalysts, hindering the commercial development and application of fuel cells, etc., and achieve easy large-scale preparation and scale Production, improved oxygen reduction efficiency, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

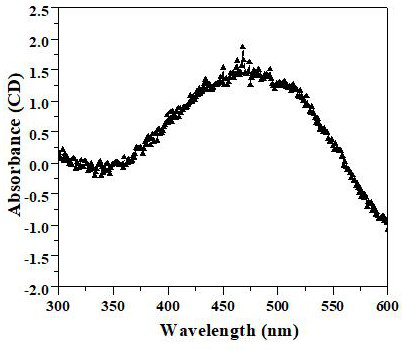

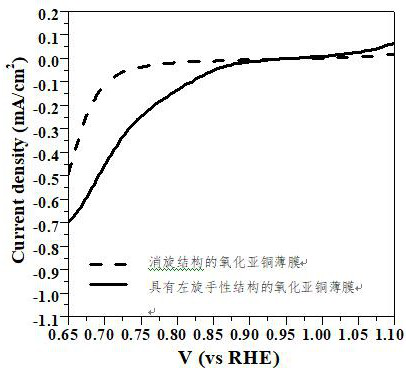

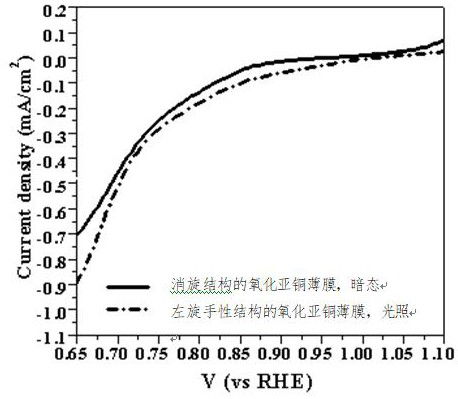

[0035] The preparation of a cuprous oxide thin film has a left-handed chiral structure, and the steps are as follows:

[0036] In the electrolyte, a saturated calomel electrode was used as a reference electrode, a platinum black electrode was used as a counter electrode, and a quartz glass sheet sputtered with a 5nm gold layer on the surface was used as a working electrode, and a constant voltage of -0.5V was applied to the working electrode to deposit Time 5min; During the deposition and growth of the film, the chiral molecules in the electrolyte induce the reactant atoms along the The preferred orientation of the crystal plane grows; after a period of deposition and growth, a cuprous oxide film with a left-handed chiral structure is obtained.

[0037] The electrolyte is L-chiral tartaric acid, CuSO 4 ·5H 2 The mixed solution of O and NaOH, the solvent is deionized water; wherein, the concentration of chiral tartaric acid is 0.2mol / L, CuSO 4 ·5H 2 The concentration of O ...

Embodiment 2

[0042] The preparation of a cuprous oxide thin film has a left-handed chiral structure, and the steps are as follows:

[0043] In electrolyte, with saturated calomel electrode as reference electrode, with platinum black electrode as counter electrode, with gold plate as working electrode, apply-0.6V constant voltage to working electrode, deposition time 20min; During the process, chiral molecules in the electrolyte induce reactant atoms along The preferred orientation of the crystal plane grows; after a period of deposition and growth, a cuprous oxide film with a left-handed chiral structure is obtained.

[0044] The electrolyte is L-chiral tartaric acid, CuSO 4 ·5H 2 The mixed solution of O and NaOH, the solvent is deionized water; wherein, the concentration of chiral tartaric acid is 0.2mol / L, CuSO 4 ·5H 2 The concentration of O is 0.2mol / L, the concentration of NaOH is 3mol / L; 4 ·5H 2 The O solution is mixed evenly so that the Cu 2+ Ions are complexed with chiral ta...

Embodiment 3

[0050] The preparation of a cuprous oxide thin film has a left-handed chiral structure, and the steps are as follows:

[0051] In electrolyte, with saturated calomel electrode as reference electrode, with platinum black electrode as counter electrode, with FTO glass as working electrode, apply-0.7V constant voltage to working electrode, deposition time 30min; During the process, chiral molecules in the electrolyte induce reactant atoms along The preferred orientation of the crystal plane grows; after a period of deposition and growth, a cuprous oxide film with a left-handed chiral structure is obtained.

[0052] The electrolyte is L-chiral tartaric acid, CuSO 4 ·5H 2 The mixed solution of O and NaOH, the solvent is deionized water; wherein, the concentration of chiral tartaric acid is 0.2mol / L, CuSO 4 ·5H 2 The concentration of O is 0.2mol / L, the concentration of NaOH is 3mol / L; 4 ·5H 2 The O solution is mixed evenly so that the Cu 2+ Ions are complexed with chiral tar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com