Energy dissipation structure for water conveying hole

A technology for water conveyance and energy dissipation, which is applied in water conservancy projects, marine engineering, instruments, etc., can solve the problems of disrepair, long service life, and broken embankments, and achieves the effect of real-time monitoring reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

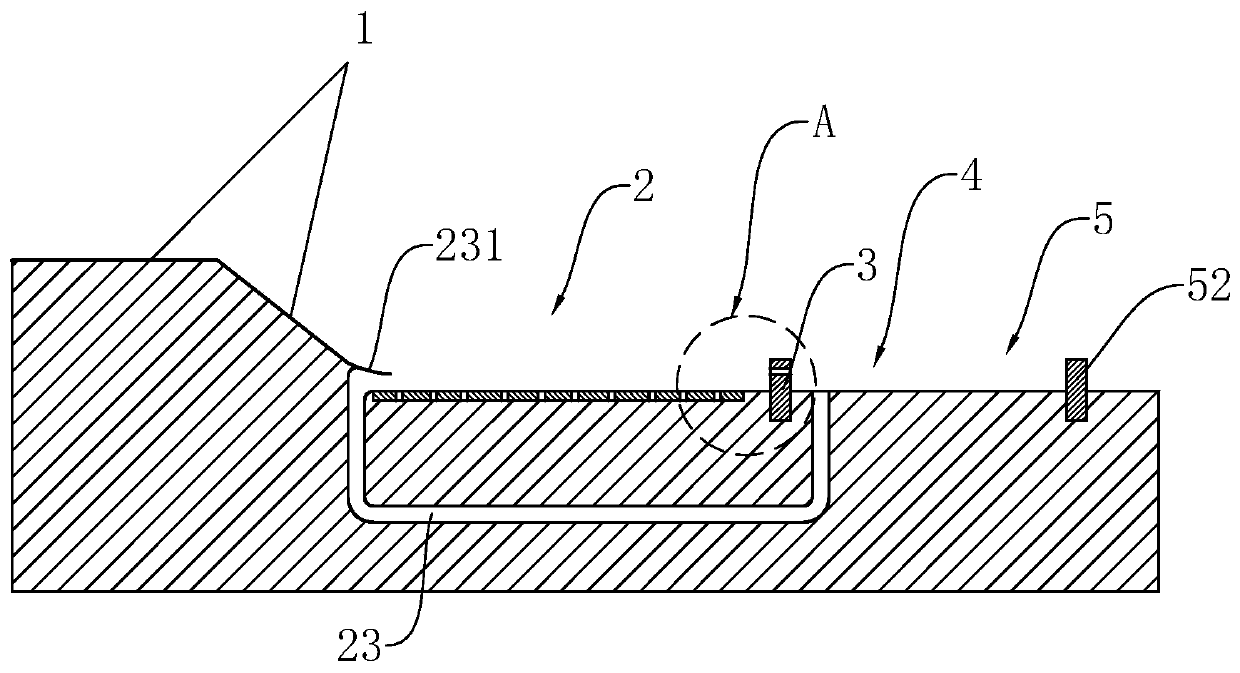

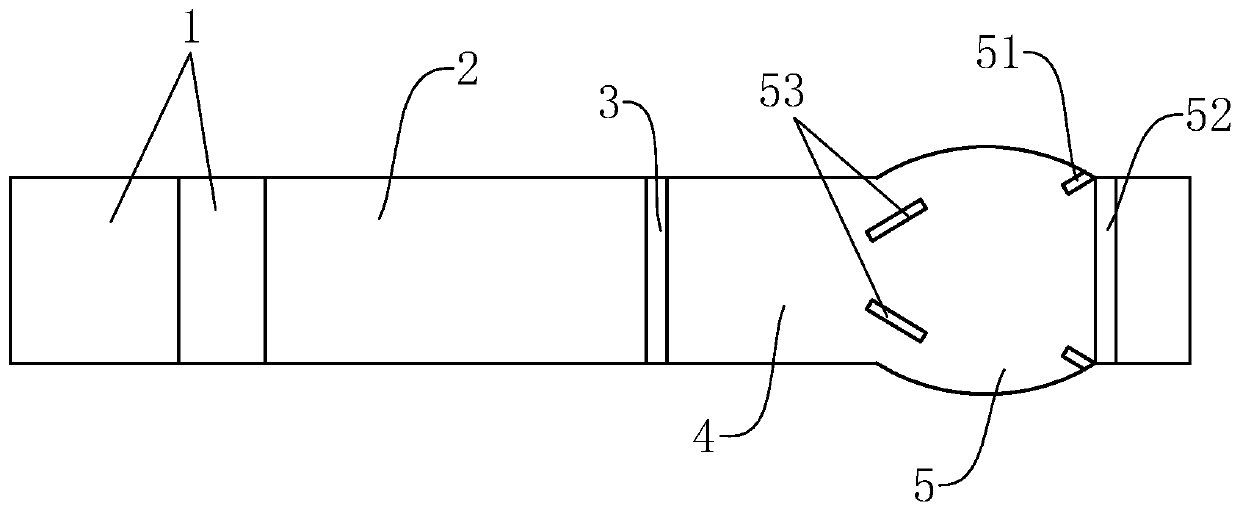

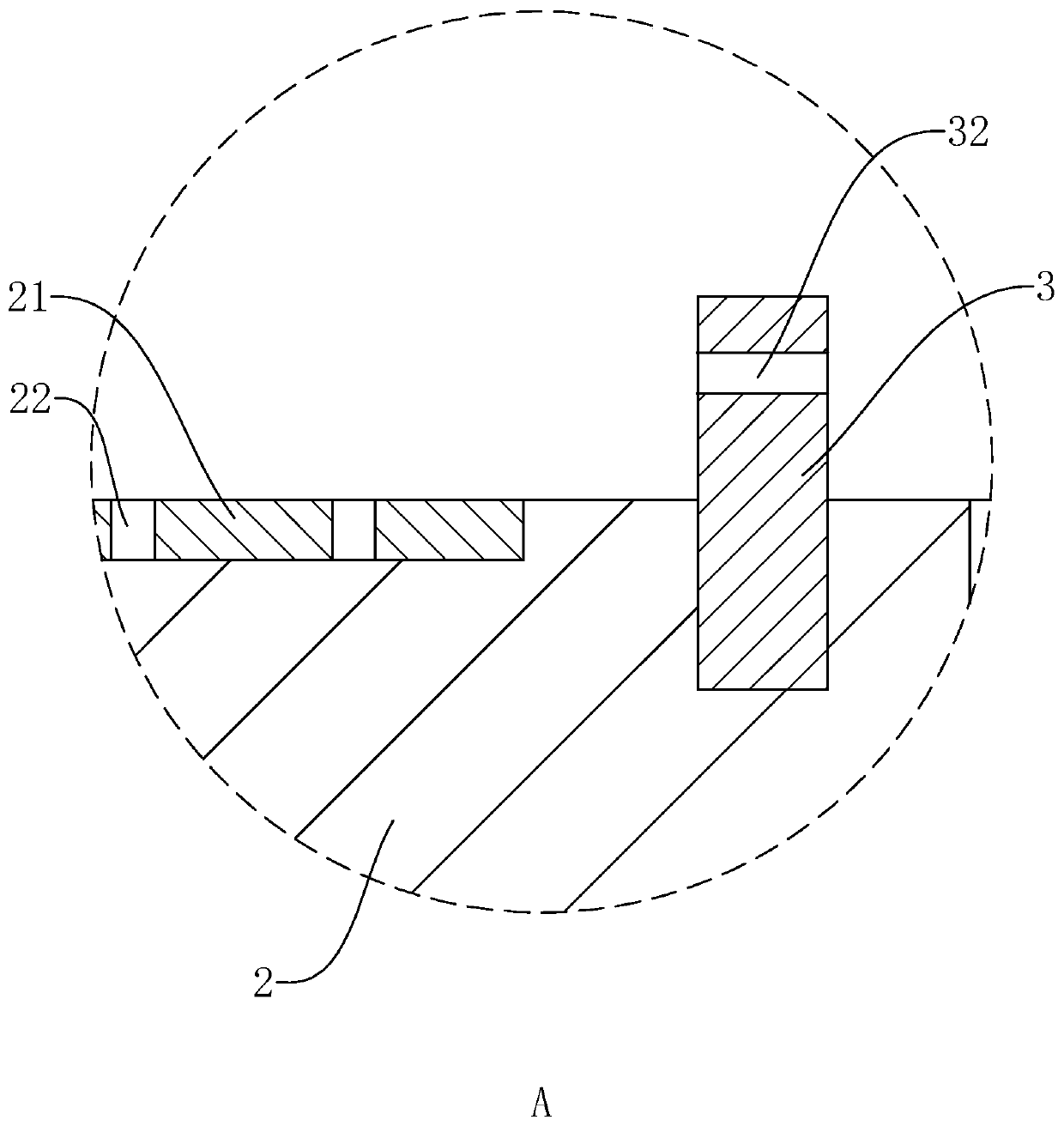

[0032] Such as figure 1 As shown, this embodiment introduces an energy dissipation structure of a water delivery tunnel, including an apron 1, a stilling basin 2, a stilling sill 3, a buffer section 4 and a second stilling basin 5 arranged sequentially from upstream to downstream, The apron 1 is located upstream of the stilling basin 2, the stilling sill 3 is located at the end of the stilling basin 2, the stilling sill 3 protrudes vertically from the bottom of the stilling basin 2, and the water first flows through the apron 1 and enters the stilling basin 2, under the blocking action of the stilling sill 3, the water flow forms a hydraulic jump upstream of the stilling sill 3, eliminating most of the water flow energy, and then enters the buffer section 4 and the second stilling pool 5, using the second stilling pool The force pool 5 performs energy dissipation for the second time, so that the water flow can flow out smoothly and slowly.

[0033] Such as figure 1 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com