A filling hydraulic forming device for special-shaped pipe fittings with variable cross-section

A technology for pressing and forming special-shaped pipe fittings, which is applied in the field of pipe forming and manufacturing. It can solve the problems of inability to actively compensate leakage, large control pressure overshoot, and component scrapping, and achieve simple and reliable structure, reduced pressure overshoot, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

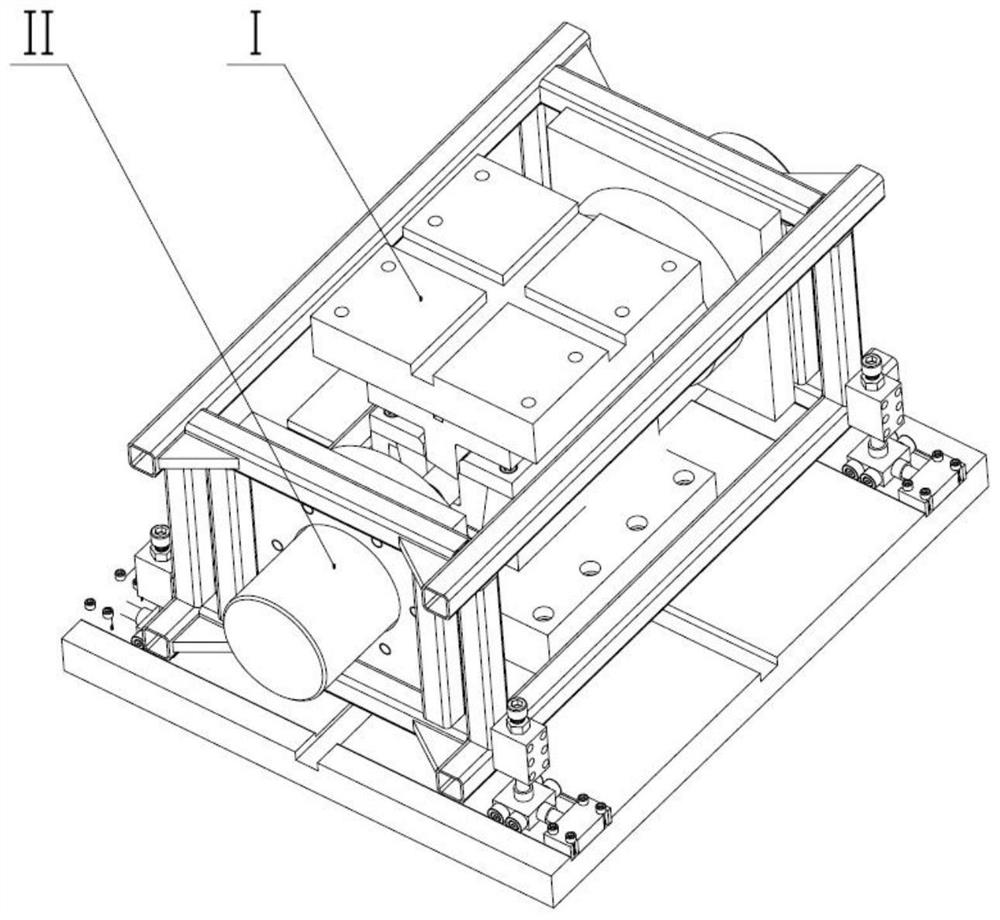

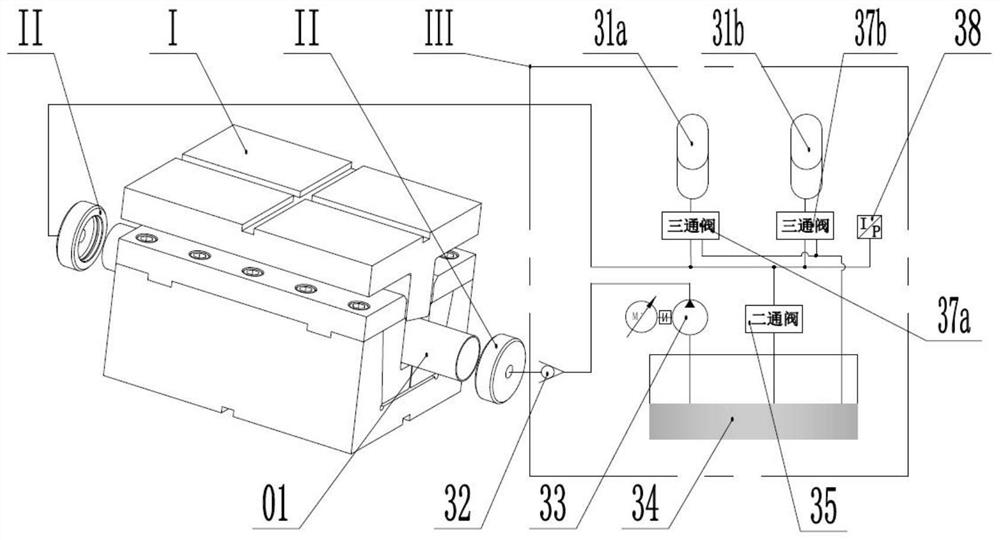

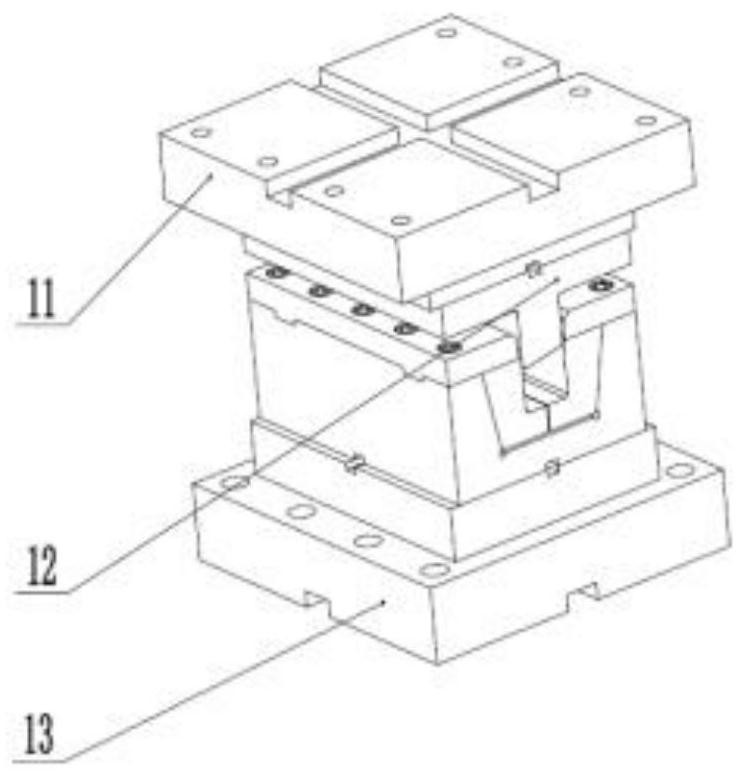

[0045] Such as Figure 1-13 As shown, this embodiment provides a hydroforming device for variable cross-section special-shaped pipe fittings, including a hydroforming mold I, a two-way follow-up sealing device II, and a medium filling and pressure control system III; the hydroforming mold I is used to place pipes and press them into shape. In this embodiment, the forming member 01 is as Figure 10-11 As shown, the preferred material of the pipe: DD14, wall thickness: 2.0mm; the two-way follow-up sealing device II is used to perform follow-up sealing on both ends of the pipe; the medium filling and pressure control system III includes a medium filling system And a pressure control system, the medium filling system is used to fill the pipe with medium, and the pressure control system is used to control the internal support pressure of the pipe.

[0046] In this implementation, if Figure 3-7 as well as Figure 13 As shown, the filling hydraulic forming mold I includes a punch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com