A processing equipment for the production of FRP wall panels

A kind of processing equipment and FRP technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of difficulty in ensuring the uniformity of brushing, affecting the quality of FRP wall panels, and low processing efficiency, so as to achieve the improvement effect. The effect of reducing processing time and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

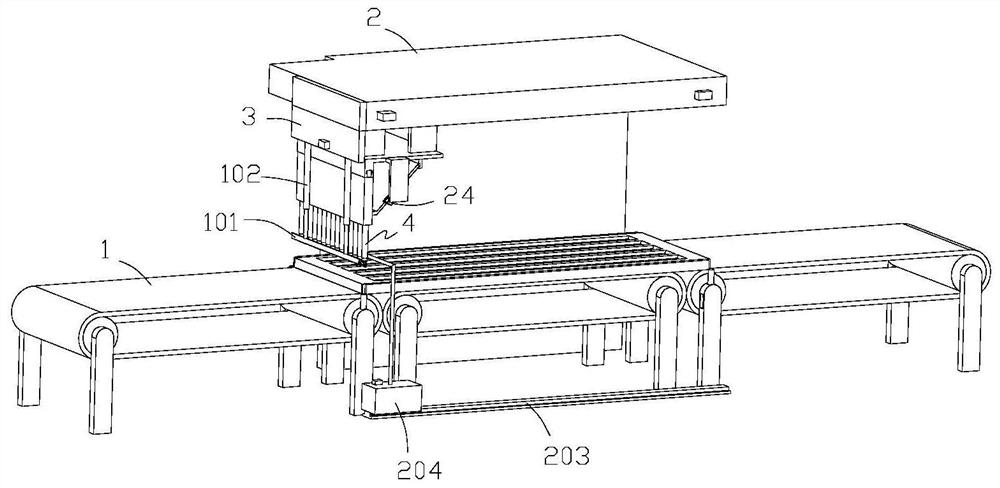

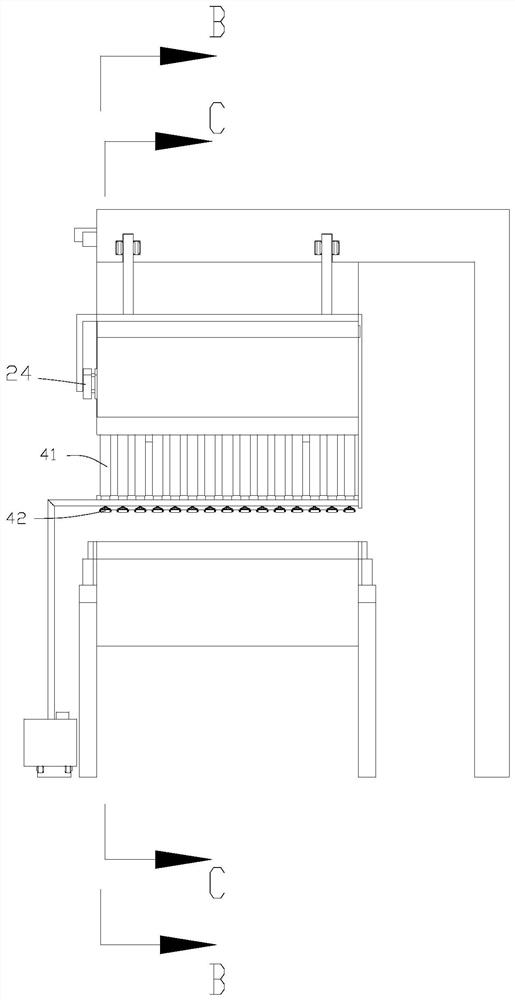

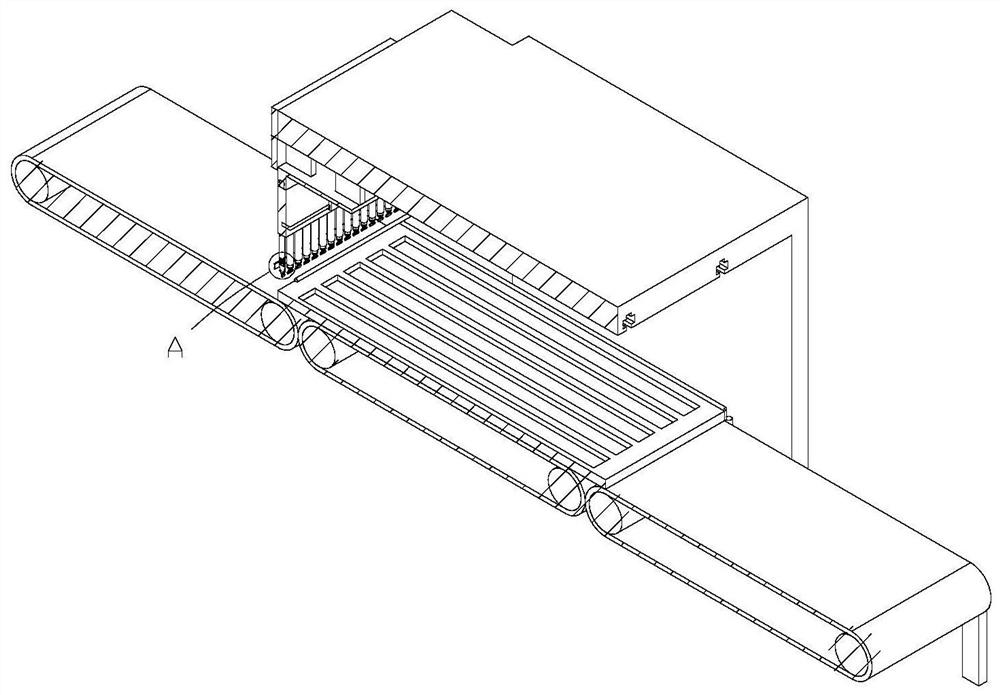

[0035] Such as Figure 1-15 As shown, a processing equipment for the production of FRP wallboards includes a conveyor belt 1 for conveying wallboards to be processed, a material pressing device, a gluing device and a positioning device, and the material pressing device is used to At least one end of the glass fiber cloth to be processed is pressed tightly on the wallboard, and the glue coating device is used to apply gel coat resin to the glass fiber cloth covered on the wallboard; specifically, the glue coating device includes a bracket 2, The gluing part and the gluing part that can reciprocate relative to the support along the length direction of the support, wherein the gluing part includes a mounting seat 3, a plurality of gluing parts 4 arranged on the mounting seat, and an electric track is provided on the support , the mounting base is connected to the electric rail through two hydraulic rods, and then the electric rail can drive the mounting base to move in the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com