Miniature high-speed optical fiber embedded centrifugal overload and vibration composite testing device

A test device and embedded technology, which is applied in vibration test, measuring device, machine/structural component test, etc., can solve the problems of large size, large installation space requirement, and large number of optical fiber channels, etc., to achieve small size and reduce occupancy The effect of less space and less signal connection lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing:

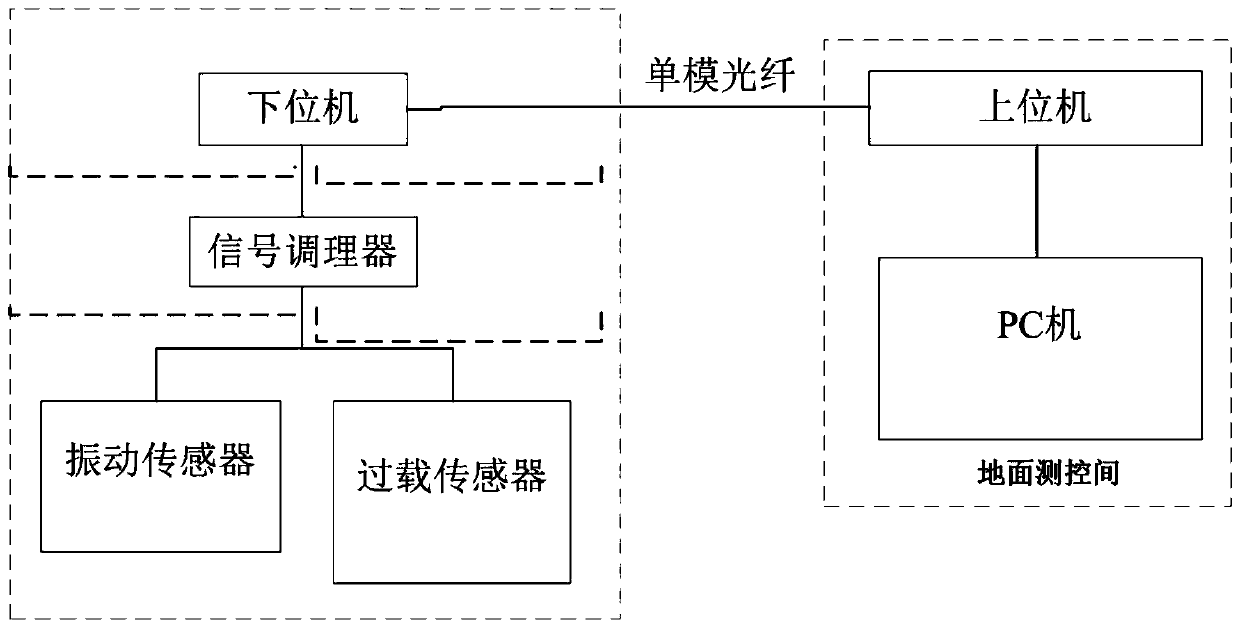

[0039] Such as figure 1 as shown,

[0040] A miniaturized high-speed optical fiber embedded centrifugal overload and vibration composite test device, including:

[0041] Vibration sensor; the vibration sensor is used to pick up the structural vibration signal of the test piece; the vibration sensor adopts a general-purpose ICP vibration acceleration sensor, the driving current is 2mA-20mA, and the power supply voltage is DC 18V-20V, which is used to pick up the structural vibration response signal of the test piece ;

[0042]The overload sensor 4; the overload sensor 4 is used for picking up the centrifugal overload signal; the vibration sensor and the overload sensor 4 are installed on the tested test piece;

[0043] Signal conditioner 3; the signal conditioner 3 is installed in the centrifuge basket and rotates together with the centrifuge basket, and the signal condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com